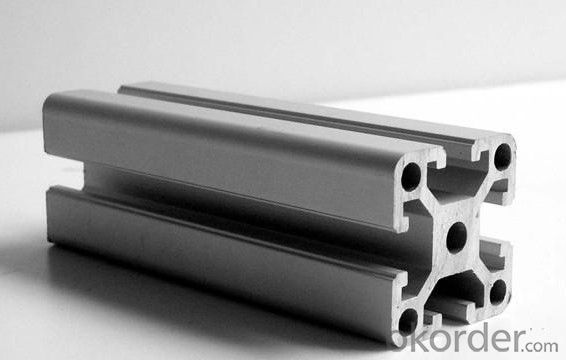

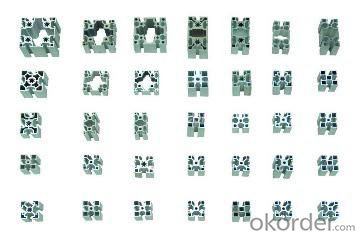

2020 T Slot Aluminum Profiles Extrusion - Aluminium Industrial Profile Hot Selling

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 0.5 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium industrial profile

used on the industrial,we extrude these profile very well.

Industial Aluminum Profile

Alloy: 6063, Temper: T5, T6.

surface:mill finished,anodized3.

widely used for building,furniture,transportation

Industial Aluminum Profile

Alloy: 6063,

Temper: T5, T6.

building,furniture,transportation,machine

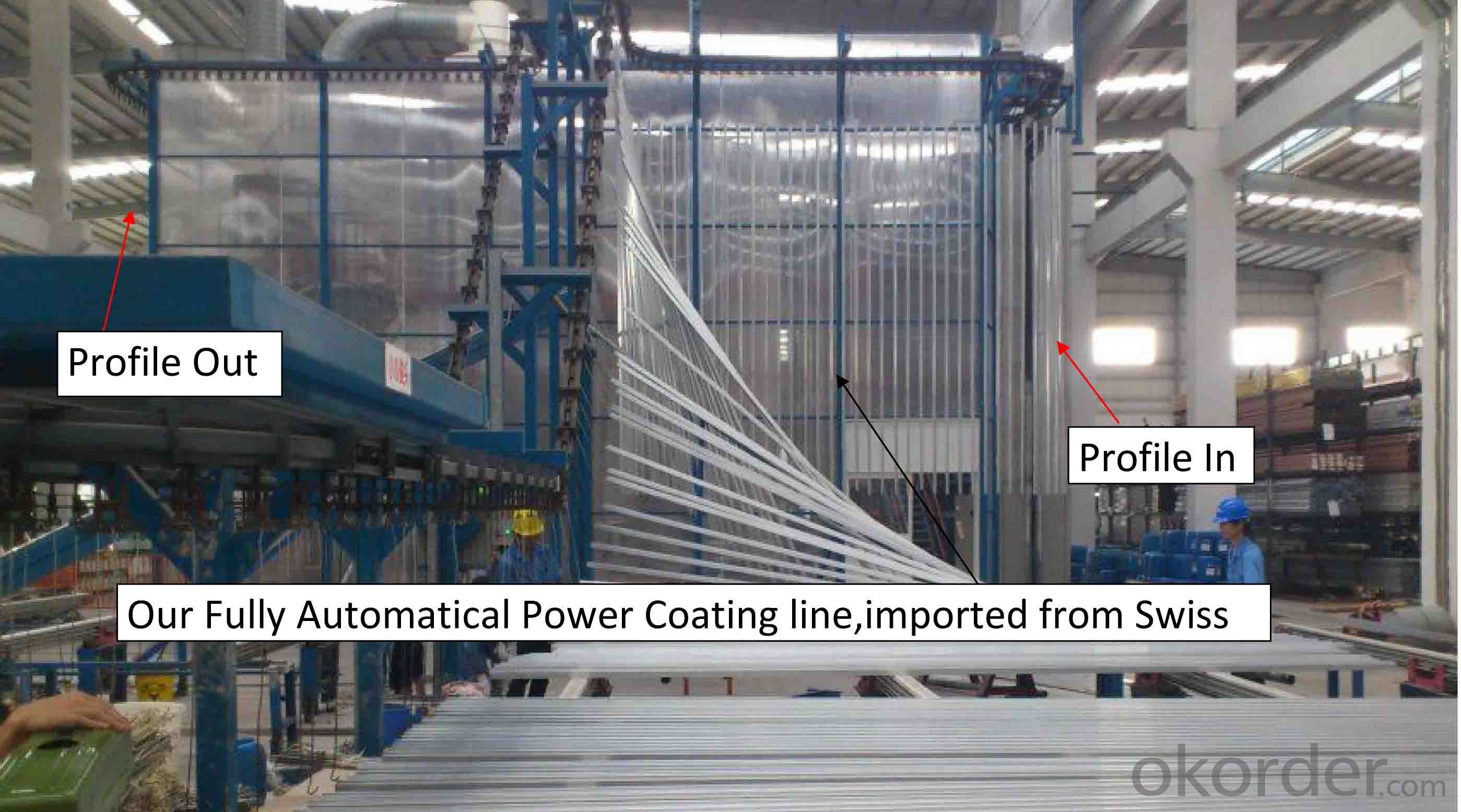

Anodized silver, anodized champagne, anodized bronze, anodized black, powder coated, electrophoresis, polished, Thermal break, wooden grain.

Length: 5.8---6 meters, depend on customers' requested.

Packing: kraft paper, carton, or on customers' requested.

Exported to different countries worldwide.

- Q: Are aluminum profiles suitable for modular construction?

- Aluminum profiles are an excellent choice for modular construction due to their many advantages. Not only are they lightweight, but they also possess considerable strength, making them perfect for supporting heavy loads in modular buildings. This structural integrity ensures the safety and stability of the entire structure. Additionally, aluminum profiles are resistant to corrosion, which is essential for modular construction projects that may face various weather conditions. This resistance enhances the durability and lifespan of the modular constructions, ultimately reducing maintenance costs in the long term. Moreover, aluminum is highly versatile and can be easily shaped and sized to meet specific design requirements. This adaptability allows architects and engineers to create innovative and functional modular structures tailored to each project's needs. Furthermore, the lightweight nature of aluminum profiles makes them easier to transport and handle during the construction process, compared to traditional building materials like steel. This lightness also helps reduce the overall weight of the modular constructions, resulting in cost savings for transportation and foundation requirements. Additionally, aluminum is a sustainable material, as it is entirely recyclable and requires less energy to produce compared to other materials. This environmentally friendly aspect aligns with the increasing demand for sustainable building practices, making aluminum profiles an ideal choice for modular construction projects. In conclusion, aluminum profiles offer numerous advantages that make them highly suitable for modular construction. Their strength, resistance to corrosion, versatility, lightweight nature, and sustainability all contribute to creating durable, customizable, and efficient modular structures.

- Q: What are the various finishes or coatings that can be applied to aluminum profiles to enhance their appearance, durability, or functionality?

- <p>Aluminum profiles can be coated with a variety of options to improve their aesthetic appeal, corrosion resistance, and performance. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; electrophoretic coating, known for its smooth finish; and thermal spraying, which involves applying a coating through a high-velocity flame. Other options are painting, which can be done in various colors, and polishing, which gives a shiny finish. Each coating option has its specific benefits and applications, depending on the requirements of the project.</p>

- Q: Can aluminum profiles be used for display cases or cabinets?

- Certainly, display cases or cabinets can make great use of aluminum profiles. These profiles are renowned for their lightweight nature, durability, and sleek, contemporary aesthetic, making them a favored option for showcasing products or housing belongings. Their versatility is further enhanced by the ease with which they can be personalized and their availability in various sizes and shapes to meet specific design needs. Moreover, these profiles possess exceptional resistance to corrosion, rendering them suitable for both indoor and outdoor applications. Additionally, their remarkable thermal conductivity can prove advantageous in regulating temperatures within display cases or cabinets. All in all, aluminum profiles offer a diverse and appealing solution for constructing display cases or cabinets.

- Q: Are aluminum profiles suitable for electrical applications?

- Yes, aluminum profiles are suitable for electrical applications. Aluminum is a lightweight, durable, and corrosion-resistant material that can effectively dissipate heat, making it ideal for electrical components such as heat sinks, enclosures, and bus bars. Additionally, aluminum profiles can be easily customized and fabricated to meet specific electrical requirements.

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum profiles used in window and door frames.

- <p>Aluminum profiles used for windows and doors can have several finishes to enhance their appearance and durability. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; thermal spraying, which applies a coating to improve resistance to wear; and electrophoretic coating, which provides a smooth, even finish. Additionally, there are finishes like polishing for a shiny look, brushing for a matte appearance, and wood grain transfer for a natural aesthetic. Each finish serves a specific purpose, from enhancing visual appeal to providing corrosion resistance and UV protection.</p>

- Q: Are aluminum profiles suitable for railway and transportation systems?

- Railway and transportation systems can greatly benefit from the use of aluminum profiles. Aluminum, being both lightweight and strong, is an ideal material for applications that demand a high strength-to-weight ratio, such as the construction of railway and transportation systems. One of the main advantages of utilizing aluminum profiles in these systems is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which effectively prevents rusting and corrosion, even in harsh environmental conditions. Consequently, this ensures the longevity and durability of the railway and transportation systems, thereby reducing maintenance requirements and costs. Furthermore, aluminum profiles offer great design flexibility. They can be effortlessly fabricated into various shapes and sizes, allowing for customization to meet the specific requirements of railway and transportation systems. This versatility allows for the creation of lightweight yet sturdy structures that can withstand the dynamic loads and vibrations experienced in transportation applications. Another advantage of aluminum profiles is their recyclability. Aluminum is one of the most recyclable materials, boasting a high recycling rate. This makes it an eco-friendly choice for railway and transportation systems, aligning with sustainable practices. Moreover, aluminum profiles possess excellent electrical conductivity and thermal properties. This makes them suitable for applications that necessitate efficient heat dissipation, electromagnetic shielding, or electrical connections in railway and transportation systems. To summarize, due to their lightweight nature, strength, corrosion resistance, design flexibility, recyclability, and electrical and thermal properties, aluminum profiles are highly suitable for railway and transportation systems. These characteristics make aluminum an ideal material for constructing transportation infrastructure that is both durable and efficient, while also being environmentally friendly.

- Q: What are the load-bearing capacities of different aluminum profile shapes?

- The load-bearing capacities of different aluminum profile shapes vary depending on various factors such as the specific alloy of aluminum used, the size and dimensions of the profile, and the specific application or use case. Aluminum profiles, also known as extrusions, come in a wide range of shapes including I-beams, T-beams, square tubes, rectangular tubes, angles, and channels. Each profile shape has its own unique load-bearing capacity due to its structural design and cross-sectional properties. For example, I-beams are known for their high load-bearing capacity due to their shape, which allows for efficient weight distribution along the flanges. They are commonly used in structural applications where heavy loads need to be supported. T-beams, on the other hand, have a load-bearing capacity similar to I-beams but with a different cross-sectional shape. They are often used in applications where a flat surface is required on one side, such as in construction or automotive industries. Square and rectangular tubes are versatile profiles that are often used in building structures, frames, and support systems. Their load-bearing capacity depends on the wall thickness and size of the tube. Angles and channels, which have a L-shaped and U-shaped cross-section respectively, are commonly used in construction and manufacturing industries. Their load-bearing capacity depends on the size and dimensions of the profile. It is important to note that the load-bearing capacities of aluminum profiles are typically provided by the manufacturer and should be consulted for specific applications. Additionally, engineering calculations and considerations such as deflection, bending moments, and safety factors should be taken into account when determining the appropriate aluminum profile shape and size for a given load-bearing requirement.

- Q: Can aluminum profiles be used in the construction of modular office spaces?

- Certainly, modular office spaces can undoubtedly utilize aluminum profiles in their construction. With their lightweight nature, durability, and exceptional structural integrity, aluminum profiles prove to be an excellent option for modular construction projects. They can be effortlessly fabricated and assembled to form a variety of components, including walls, partitions, doors, windows, and framing systems for modular office spaces. Furthermore, aluminum profiles offer immense design flexibility, enabling customization and adaptation to diverse office layouts and requirements. Moreover, they possess high resistance to corrosion, which proves particularly advantageous in office environments susceptible to moisture and humidity. In essence, aluminum profiles offer a multitude of benefits in terms of strength, versatility, and aesthetics, rendering them a favored choice for construction in modular office spaces.

- Q: What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles possess several fire-resistant properties that make them a suitable choice for various applications. First and foremost, aluminum has a high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), which means it can withstand high temperatures without melting or losing its structural integrity. Moreover, aluminum has a low ignition point, meaning it requires a higher temperature to ignite compared to other metals. This property makes it less susceptible to catching fire when exposed to heat or flames. In the event of a fire, aluminum profiles form a protective layer of aluminum oxide on their surface due to their natural oxide layer. This layer acts as a barrier, preventing the further spread of flames and inhibiting the combustion process. Additionally, the aluminum oxide layer is highly heat resistant, providing additional protection against high temperatures. Furthermore, aluminum profiles are non-combustible, meaning they do not contribute to the spread of fire. This characteristic is crucial in fire safety as it helps to contain the fire within a specific area and prevent its rapid expansion. Overall, the fire-resistant properties of aluminum profiles, including high melting point, low ignition point, the formation of a protective oxide layer, and non-combustibility, make them a reliable choice for various applications where fire safety is a concern.

- Q: Are aluminum profiles suitable for medical equipment and devices?

- Yes, aluminum profiles are suitable for medical equipment and devices. Aluminum is a versatile material that offers several advantages for medical applications. Firstly, it is lightweight, making it ideal for portable medical devices. This allows for ease of transportation, especially in emergency situations. Additionally, aluminum is corrosion-resistant, which is crucial for maintaining the sterility and cleanliness of medical equipment. The material is also durable and can withstand harsh environments and regular cleaning and sterilization procedures. Furthermore, aluminum profiles can be easily customized and fabricated into various shapes and sizes, making them adaptable for different medical device designs. Overall, the properties of aluminum make it a reliable and suitable choice for medical equipment and devices.

Send your message to us

2020 T Slot Aluminum Profiles Extrusion - Aluminium Industrial Profile Hot Selling

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 0.5 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords