Aluminum Profiles Extrusion 6081-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

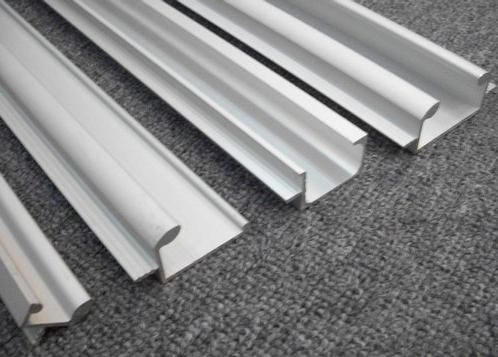

1 Specifications of Aluminum Profiles 6081-T5

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6081-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles 6081-T5

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles 6081-T5

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: Explain how aluminum profiles contribute to the energy efficiency of a building.

- <p>Aluminum profiles significantly enhance the energy efficiency of a building through several mechanisms. They are lightweight yet strong, reducing the overall weight of the structure and the energy required for construction. Their excellent thermal conductivity allows for efficient heat transfer, which can be managed with proper insulation to reduce heat loss. Aluminum profiles also facilitate better window and door sealing, minimizing drafts and heat leakage. Additionally, their high reflectivity can help in reflecting solar heat, reducing the need for cooling. Lastly, aluminum profiles can be used in the construction of solar panels and other renewable energy systems, further contributing to a building's energy efficiency.</p>

- Q: T6 should be 140MPa, while the aluminum profile specification should be 150MPa. Should that be the standard?Code for design of glass curtain wall... And the calculation formula of bolt connection, what is the compressive strength value of aluminum profile?Prawns help you, 3Q~

- Personal advice: 1. The degree of occlusion is enhanced by the gauge before stretching. Up and down / adjust the bearing, to prevent the deviation caused by the above results of the bearing.Check steel raw material is a batch product manufacturer. The factory certificate is the same.

- Q: This question asks about the effects of utilizing aluminum profiles in the construction industry on the environment.

- <p>The environmental impacts of using aluminum profiles in construction are multifaceted. On the positive side, aluminum is lightweight and strong, reducing the amount of material needed and potentially decreasing energy consumption in transportation. It is also recyclable, which can reduce waste and the need for raw material extraction. However, the production of aluminum requires significant energy, often from non-renewable sources, contributing to carbon emissions. Additionally, while recycling reduces environmental impact, it still consumes energy and can generate waste. The longevity and durability of aluminum can lead to less frequent replacement, reducing construction waste, but improper disposal can lead to pollution. Overall, the environmental impact depends on the balance between these factors and the specific practices of aluminum production and use in construction.</p>

- Q: This question asks about the variety of dimensions and forms that aluminum profiles can come in.

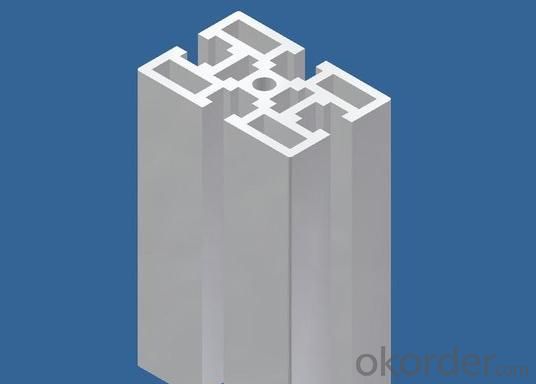

- <p>Aluminum profiles are available in a wide range of sizes and shapes to suit various applications. Common shapes include rectangular, square, circular, and special profiles like angles, channels, and tees. Sizes can vary from thin strips to thick bars, with specific dimensions tailored to the needs of the project. The profiles can be flat, hollow, or have complex cross-sectional geometries. They are also available in different surface finishes, such as anodized, painted, or powder-coated, to enhance their appearance and durability. The selection of aluminum profiles depends on the structural requirements, design specifications, and the industry they are intended for, such as construction, automotive, or aerospace.</p>

- Q: Ask you, China aluminum plate production factory, supply distribution in the provinces in which the details, please.

- A large share of the domestic market, mainly in Shanghai, Guangdong, Chongqing and other provinces and cities, the other areas are relatively small.From the regional distribution, aluminum production in East China is the highest, followed by South Central China. The provinces and municipalities in Jiangsu, Zhejiang, Guangdong and Chongqing have the highest output.Fengcheng global resource recycling technology development Co., Ltd.

- Q: How can I distinguish the aluminum profiles in the building and the aluminum in the industry?

- Door frames, aluminum profiles and doors and windows, aluminum profiles are in the building. Your picture is a line of scaffold material, usually in industrial material.

- Q: The question asks if aluminum profiles can be tailored to fit particular specifications or needs.

- <p>Yes, aluminum profiles can be customized to meet specific requirements. This customization can include altering the length, shape, thickness, and surface treatment of the profiles to fit the needs of various applications. Manufacturers often offer a range of standard sizes and finishes, but they can also create bespoke profiles through processes like extrusion, cutting, and bending. Customization allows for the creation of precise fits and functional designs tailored to individual projects, enhancing both aesthetics and performance.</p>

- Q: Are aluminum profiles resistant to chemicals or solvents?

- Yes, aluminum profiles are generally resistant to chemicals and solvents. Due to their natural oxide layer, they exhibit good corrosion resistance and can withstand exposure to many common chemicals and solvents without significant degradation or damage. However, it is important to note that the specific resistance may vary depending on the type of chemical or solvent involved, concentration, temperature, and exposure duration.

- Q: What are the different assembly options available for aluminum profiles?

- Depending on specific requirements and applications, there are various assembly options available for aluminum profiles. Here are some commonly used methods: 1. For a strong and secure connection that allows frequent disassembly or adjustment, mechanical fastening is preferred. This involves using screws, bolts, or rivets to join aluminum profiles together. 2. When maximum strength and rigidity are needed, welding is an ideal choice. Aluminum profiles can be welded using techniques such as TIG or MIG welding, resulting in a seamless and strong joint. 3. Adhesive bonding is suitable for lightweight applications or when aesthetics are important. It provides a clean and seamless appearance without visible fasteners, although it may not be as strong as mechanical fastening or welding. 4. Aluminum profiles often have T-slot designs that allow the use of connecting elements like T-nuts, connectors, and brackets. These elements can be easily inserted into the slots and tightened to create a secure and adjustable joint, making it useful for flexible and easily reconfigurable applications. 5. Corner brackets are specifically designed to connect aluminum profiles at right angles. They can be easily attached using screws or bolts, providing a strong and rigid joint. They are commonly used in frame construction or for creating corners in structural applications. 6. Some aluminum profiles feature interlocking systems that eliminate the need for additional fasteners or connectors. These systems utilize specially designed shapes or grooves that fit together, ensuring a secure connection. They are often used in modular structures or systems that require quick assembly and disassembly. Ultimately, the choice of assembly method for aluminum profiles depends on factors such as strength requirements, aesthetics, ease of assembly, and the specific application or industry. Careful consideration of these factors is important when selecting the most suitable assembly option for a given project.

- Q: What are the different types of surface coatings for aluminum profiles?

- There are several different types of surface coatings for aluminum profiles, including anodizing, powder coating, liquid coating, and electroplating.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1991 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Profiles Extrusion 6081-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords