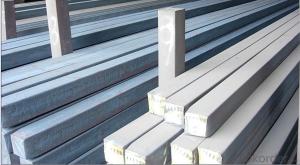

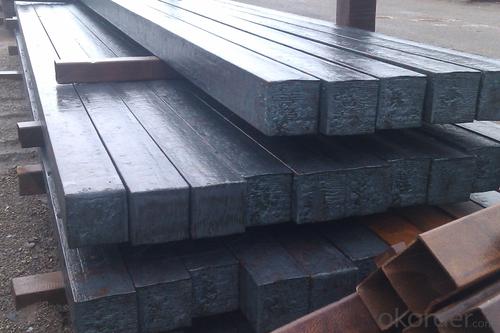

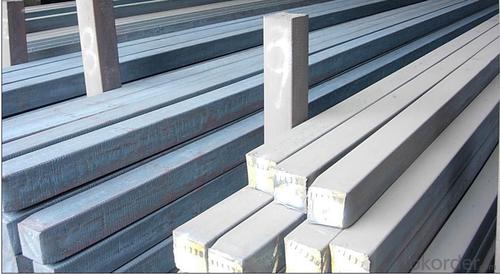

Prime Q275 120mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 120mm Square Alloy Steel Billet

Description of Prime Q275 120mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 120mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 120mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 120mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 120mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the potential applications of steel billets in the electronics aftermarket?

- Steel billets have numerous potential applications in the electronics aftermarket. One possible application is the production of electronic enclosures or casings. Steel billets can be machined and shaped into various forms and sizes to create sturdy and reliable enclosures that protect electronic components. These enclosures provide durability and protection against environmental factors such as moisture, dust, and impact. Additionally, steel billets can be used in the manufacturing of various electronic components. For example, they can be utilized to create connectors, pins, sockets, and other small parts that are essential for electronic devices. Steel's high strength and conductivity make it an ideal material for these components, ensuring reliable performance and efficient signal transmission. Furthermore, steel billets can be employed in the production of heat sinks for electronic devices. Heat sinks are crucial in dissipating heat generated by electronic components and preventing overheating, which can lead to performance issues or even component failure. Steel's excellent thermal conductivity makes it a suitable material for heat sinks, allowing efficient heat transfer and ensuring the proper functioning of electronic devices. Moreover, steel billets can be utilized in the manufacturing of racks and cabinets used for housing and organizing electronic equipment. These structures provide a safe and secure environment for storing and accessing electronic devices in various settings, such as data centers, telecommunications facilities, or server rooms. Steel's durability and load-bearing capabilities make it an ideal choice for such applications, ensuring the protection and organization of electronic equipment. In summary, steel billets have a range of potential applications in the electronics aftermarket. Whether it is in the production of enclosures, electronic components, heat sinks, or racks and cabinets, steel's strength, conductivity, durability, and thermal properties make it a versatile material for various electronic applications.

- Q: How are steel billets used in the manufacturing of electrical components?

- The advantageous properties and suitability of steel billets make them commonly used in the manufacturing of electrical components. This process begins by producing steel billets, which are solid rectangular or square bars of steel formed through casting or hot rolling. When manufacturing electrical components, steel billets act as the raw material that undergoes various processes to become specific components. An example of this is the production of transformer cores, which are essential components in electrical transformers. Transformer cores made from steel billets offer high magnetic permeability, low hysteresis loss, and low electrical conductivity, making them perfect for magnetic induction applications. To manufacture transformer cores, the steel billets are heated and then shaped into thin laminations by passing them through a series of rolling mills. These laminations are stacked together and insulated with materials like varnish or paper, creating a core that efficiently transfers electrical energy between coils. Steel billets are also utilized in the production of electrical connectors, terminals, and busbars. These components require high strength, excellent electrical conductivity, and resistance to corrosion. Steel billets can be further processed using methods like forging, machining, or extrusion to create these components. Apart from transformers and electrical connectors, steel billets can be employed in manufacturing other electrical components such as motor cores, switchgear panels, and circuit breaker parts. The versatility of steel billets allows for the production of components with various shapes and sizes, catering to the specific requirements of the electrical industry. In conclusion, steel billets play a crucial role in the manufacturing of electrical components by providing a strong, durable, and cost-effective raw material that can be shaped and processed to meet the diverse needs of the electrical industry.

- Q: What are the cost implications of using steel billets in manufacturing?

- Using steel billets in manufacturing can have several cost implications. First and foremost, the cost of steel billets themselves needs to be considered. The price of steel billets can vary depending on factors such as market demand, availability, and the grade of steel used. Therefore, fluctuations in steel prices can directly impact the cost of manufacturing. Additionally, the cost of transportation and logistics needs to be taken into account. Steel billets are heavy and bulky, requiring specialized handling and transportation methods. This can result in higher shipping costs, especially if the manufacturing facility is located far away from the source of steel billets. Furthermore, the cost of processing and shaping steel billets into the desired form for manufacturing needs to be considered. This includes expenses associated with cutting, welding, forging, and any other necessary fabrication processes. The complexity of these processes and the required machinery can have a significant impact on the overall cost of using steel billets. Another cost implication is related to the quality of steel billets. Inferior quality billets can lead to lower product quality and higher rejection rates, resulting in increased manufacturing costs. Therefore, it is important to source steel billets from reputable suppliers to ensure consistent quality and minimize the risk of defects. In terms of long-term costs, the durability and strength of steel make it an attractive choice for manufacturing. Steel is known for its longevity and resistance to wear and tear, reducing the need for frequent replacements and repairs. This can result in long-term cost savings for manufacturers. Lastly, it is essential to consider the environmental and sustainability aspects associated with using steel billets. Steel production is energy-intensive and can have a significant carbon footprint. Increasingly, manufacturers are being held accountable for their environmental impact, which can lead to additional costs in terms of compliance with regulations or implementing sustainable practices. In summary, the cost implications of using steel billets in manufacturing involve the price of the billets themselves, transportation costs, processing expenses, quality considerations, long-term durability, and sustainability factors. Careful analysis of these cost factors is crucial for manufacturers to make informed decisions and optimize their manufacturing processes.

- Q: What is the chemical composition of a typical steel billet?

- A typical steel billet is primarily composed of iron (Fe) along with small amounts of carbon (C) and other alloying elements such as manganese (Mn), silicon (Si), sulfur (S), and phosphorus (P).

- Q: What are the different methods of steel billet surface cleaning?

- Steel billet surface cleaning can be achieved through various methods, each with its own set of advantages and disadvantages. Some commonly used methods include: 1. Shot Blasting: By propelling small metallic or non-metallic particles at high speeds onto the billet surface, rust, scale, and other contaminants are effectively removed. Shot blasting is a quick and efficient method for cleaning large surfaces. However, it may result in surface roughness and may not be suitable for all types of steel. 2. Acid Pickling: This method involves immersing the steel billet in an acid solution, typically hydrochloric or sulfuric acid, to eliminate scale and rust. The acid reacts with the surface contaminants, dissolving them and leaving a clean surface. Acid pickling is particularly effective in removing stubborn scale and rust. However, it requires careful handling of corrosive acids and proper waste disposal. 3. Mechanical Cleaning: Mechanical cleaning methods utilize abrasive tools or brushes to physically scrub the billet surface. This can be done manually or with the assistance of machinery. Mechanical cleaning effectively removes loose contaminants and scale. However, it may not be suitable for heavily rusted or firmly adhered contaminants. 4. High-Pressure Water Jetting: This method employs high-pressure water jets to cleanse the billet surface. The force of the water effectively removes scale, rust, and other contaminants. High-pressure water jetting is environmentally friendly as it does not involve the use of chemicals. However, it may not be as effective in removing heavy scale or rust. 5. Ultrasonic Cleaning: Ultrasonic cleaning entails immersing the steel billet in a tank filled with a cleaning solution and subjecting it to high-frequency ultrasonic vibrations. These vibrations generate tiny bubbles in the cleaning solution, which collapse on the billet surface, effectively eliminating contaminants. Ultrasonic cleaning is highly efficient in removing even microscopic particles and can reach complex geometries. However, it may not be suitable for large-scale cleaning operations. Each method possesses its own unique strengths and limitations. The selection of a specific method depends on factors such as the type and condition of the surface contaminants, time and cost constraints, and the desired surface finish.

- Q: How are steel billets used in the production of bars and rods?

- Steel billets are an essential raw material used in the production of bars and rods. These billets, which are usually produced through a process called continuous casting, are solid blocks of semi-finished steel with a square or rectangular cross-section. To transform steel billets into bars and rods, several steps are involved. First, the billets are reheated to a specific temperature in a furnace to make them more malleable. This heating process, known as soaking, helps to homogenize the steel's composition and improve its plasticity. Once the billets reach the desired temperature, they are then passed through a series of rollers in a process called hot rolling. The rollers apply pressure to the billets, gradually reducing their cross-sectional area and elongating them into long, slender shapes. This hot rolling process helps to refine the grain structure of the steel, align its crystalline structure, and improve its mechanical properties. After hot rolling, the bars and rods are often subjected to further processes, such as cooling, straightening, and cutting. Cooling is crucial to prevent the steel from becoming too brittle, while straightening ensures the final product has the desired shape and dimensions. Finally, the bars and rods are cut into specific lengths, ready to be used in various industries such as construction, automotive, and manufacturing. In summary, steel billets form the starting point for the production of bars and rods. Through processes like reheating, hot rolling, and subsequent treatments, these billets are transformed into high-quality, durable bars and rods that are widely used in various applications.

- Q: What are the challenges faced by the steel billet industry?

- The steel billet industry encounters numerous obstacles that affect its operations and profitability. One notable challenge is the ever-changing global demand for steel products. Economic cycles exert a significant influence on the industry, directly impacting the demand for steel billets. When the economy experiences a downturn or slower growth, the demand for steel products decreases, resulting in excess inventory and reduced prices. Consequently, steel billet manufacturers face lower profit margins and struggle to sustain their operations. Additionally, the industry confronts fierce competition from other steel producers, particularly those in emerging markets. Countries like China and India have considerably expanded their steel production capacities in recent years, leading to a surplus in the global market. This oversupply drives down prices, making it arduous for steel billet manufacturers to compete on cost and maintain profitability. Moreover, the availability and pricing of raw materials pose another significant challenge for the industry. The production of steel billets necessitates a consistent supply of iron ore and other raw materials, which are susceptible to price fluctuations and disruptions in the supply chain. Any interruptions or fluctuations in the availability or cost of these raw materials can adversely affect the overall cost structure and profitability of the steel billet industry. Furthermore, environmental regulations and concerns about sustainability present an additional hurdle for the steel billet industry. Steel manufacturing is a resource-intensive process that generates substantial emissions and waste. As governments and consumers become more conscientious about environmental issues, steel billet manufacturers must invest in cleaner technologies and comply with stricter regulations. These investments can be costly and impact the industry's profitability and competitiveness. Lastly, the industry grapples with the challenge of technological advancements and innovation. To enhance production processes, improve product quality, and meet evolving customer demands, steel billet manufacturers must consistently invest in research and development. Staying abreast of the latest technological advancements necessitates significant investment, which can be particularly challenging for smaller players in the industry. In conclusion, the steel billet industry confronts various challenges, including fluctuating global demand, intense competition, raw material availability and pricing, environmental regulations, and technological advancements. Adapting to these challenges requires strategic planning, continuous improvement, and investment in innovation to remain competitive and sustainable in the market.

- Q: Can steel billets be used in the production of energy infrastructure?

- Yes, steel billets can be used in the production of energy infrastructure. Steel is a widely used material in the construction of various energy infrastructure components such as power plants, transmission towers, pipelines, and wind turbine towers. Steel billets, which are semi-finished steel products, can be further processed and shaped into the required forms for these infrastructure projects. The strength, durability, and versatility of steel make it suitable for withstanding the harsh conditions and heavy loads associated with energy infrastructure. Additionally, steel offers excellent corrosion resistance, which is crucial for infrastructure exposed to the elements. Overall, steel billets play a vital role in the production of energy infrastructure, contributing to the reliable and efficient generation, transmission, and distribution of energy.

- Q: How are steel billets used in the manufacturing of oil and gas equipment?

- The production of oil and gas equipment heavily relies on steel billets. These semi-finished steel products act as the foundation for creating various equipment used in the oil and gas industry. Steel billets are primarily used in pipe manufacturing. To withstand high pressure, extreme temperatures, and corrosive environments, oil and gas pipes require raw materials that can meet these demanding requirements. Steel billets are heated, pierced, and elongated through extrusion to form seamless pipes. Alternatively, they can be rolled and welded to create longitudinally welded pipes. Additionally, steel billets are essential in the production of valves, fittings, and flanges. Valves are critical in controlling the flow of oil and gas, while fittings connect pipes and change their direction. Flanges provide a means of connecting pipes, valves, and other equipment through bolting. All of these components require steel billets as a starting material, which are then machined, shaped, and heat-treated to meet necessary specifications. Furthermore, steel billets are utilized in the fabrication of drilling equipment and offshore structures. Drilling equipment, including drill bits, drill collars, and drill pipes, are vital for oil and gas exploration and extraction. High-quality steel billets are crucial to ensure the strength and durability of these components, which endure intense forces and harsh conditions. Offshore structures, such as platforms and rigs, also rely on steel billets to construct frameworks and support systems that withstand the challenging marine environment. In conclusion, steel billets are irreplaceable in the manufacturing of oil and gas equipment. They serve as the raw material for pipes, valves, fittings, flanges, drilling equipment, and offshore structures. By starting with high-quality steel billets, manufacturers can produce durable and reliable equipment capable of withstanding the demanding conditions of the oil and gas industry.

- Q: What is the role of steel billets in the construction of residential buildings?

- Steel billets play a crucial role in the construction of residential buildings. These long, rectangular-shaped steel bars serve as the primary raw material for the production of various structural components used in the construction process. One of the key applications of steel billets is in the fabrication of reinforced concrete structures. Reinforced concrete is widely used in building foundations, columns, beams, and slabs due to its high strength and durability. Steel billets are used to manufacture rebar, which is then embedded within the concrete to provide tensile strength and enhance the structural integrity of the building. The use of steel reinforcement ensures that the building can withstand external forces, such as wind, seismic activity, and the weight of the structure itself. Additionally, steel billets are utilized in the production of steel beams and columns. These components are essential for supporting the weight of the building and transferring loads from the upper floors to the foundation. Steel beams offer superior strength and rigidity, allowing for the construction of open, spacious interiors without the need for excessive support walls. This not only provides flexibility in design but also maximizes the usable space in residential buildings. Steel billets are also utilized in the construction of stairs, handrails, and balconies. These elements require high-strength materials to ensure the safety and longevity of the structure. Steel billets provide the necessary strength and stability to these components, allowing for safe and secure access to different areas of the building. In summary, steel billets are crucial in the construction of residential buildings as they serve as the raw material for various structural components. From reinforced concrete structures to steel beams, columns, and other architectural elements, steel billets play a vital role in ensuring the strength, durability, and overall safety of residential buildings.

Send your message to us

Prime Q275 120mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords