0.3-3mm thickness 321 Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

1.2

Width:

1219

Length:

2000

Net Weight:

23

cold rolled 0.3-3mm thickness 321 stainless steel sheet

Product Description

1.Product Info

Item | cold rolled 0.3-3mm thickness 321 stainless steel sheet |

| Specification | Width:500mm---2000mm |

| Thickness:0.3mm---120mm(or as your requirement) | |

| Length:1000mm----6000mm | |

| Application | Petroleum,Chemical enginnering,Pharmaceutical ,Paper--making,Food,Nuclear power and other industries. |

| Package | Standard seaworthy package(wooden boxes package,and other package or as your requirement). |

| Delivery time | 7----10working days after the order received. |

| Delivery terms | FOB,CFR,CIF,CNF etc. |

| Brand name | TISCO,LISCO,ZPSS,BAOSTEEL. |

| Standard | JIS,AISI,ASTM,DIN,EN,GB. |

2.surface treatment

| Surface finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| No.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

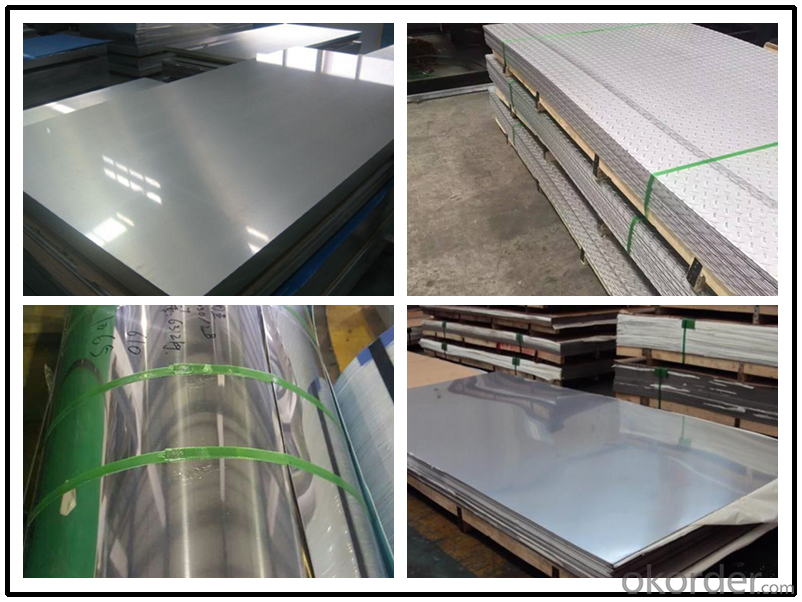

3.product pictures show

Packaging & Shipping

1.Package :Standard seaworthy package(wooden boxes package and other package or as your requirements).

2.Shipping:We will arrange the shipment within 7---10 working days after we get the order.

Detailed Images

Packaging & Shipping

Application

- Q: Several processing techniques of colored stainless steel

- 1, water plating (mainly black, note 304 plating water plating, color instability, slightly blue, mirror surface is particularly obvious, treatment method for high temperature without fingerprint processing, but the surface will be brown)2, electroplating - PVD vacuum plasma plating (can be plated sapphire blue, black, coffee, seven color, zirconium, gold, bronze, bronze, rose, champagne, golden, light green)

- Q: Are stainless steel sheets suitable for outdoor signage?

- Yes, stainless steel sheets are suitable for outdoor signage. Stainless steel is a popular choice for outdoor applications due to its durability, corrosion resistance, and aesthetic appeal. It is highly resistant to rust and can withstand harsh weather conditions, making it ideal for outdoor signage that needs to withstand exposure to rain, sunlight, and extreme temperatures. Additionally, stainless steel sheets can be easily customized and fabricated to create various designs and shapes, making it a versatile material for outdoor signage. Its sleek and polished finish also adds a professional and modern look to any signage. Overall, stainless steel sheets are a reliable and long-lasting option for outdoor signage.

- Q: Why do galvanized and stainless steel sheets buy more expensive than thin ones?

- Galvanized sheet refers to the surface coated with a layer of zinc steel plate. Zinc plating is an economical and effective method of corrosion protection, and about half of the world's zinc production is used in this process.

- Q: Are stainless steel sheets resistant to scaling?

- Yes, stainless steel sheets are highly resistant to scaling. Due to their chromium content, they form a protective layer that prevents oxidation and scaling even at high temperatures.

- Q: Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are generally resistant to pitting and crevice corrosion. Stainless steel is known for its high corrosion resistance due to the presence of chromium, which forms a passive oxide layer on the surface of the material, protecting it from corrosion. This oxide layer acts as a barrier, preventing the penetration of corrosive substances that could cause pitting and crevice corrosion. However, it is important to note that the resistance to pitting and crevice corrosion can vary depending on the specific grade of stainless steel and the environmental conditions in which it is exposed. Some grades of stainless steel, such as 316 or 317, have enhanced resistance to these types of corrosion. In addition, certain aggressive environments, such as those with high chloride concentrations or acidic conditions, can still pose a risk to stainless steel and may require the use of more corrosion-resistant grades or additional protective measures. Overall, stainless steel sheets are highly resistant to pitting and crevice corrosion, but the specific grade and environmental factors should be considered for optimal performance.

- Q: What does stainless steel plate mean?

- The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and the internal structure of the alloy, and the main role is chromium. Chromium has high chemical stability, can form a passive film on the steel surface, so that the metal is isolated from the outside, protect the steel plate from oxidation and increase the corrosion resistance of the steel plate. When the passive film is destroyed, the corrosion resistance will decrease.

- Q: Are stainless steel sheets suitable for high-temperature applications?

- Stainless steel sheets are well-suited for high-temperature applications. Renowned for their outstanding heat resistance properties, stainless steel proves to be an optimal material for utilization in environments with elevated temperatures. It possesses the ability to endure extreme heat while retaining its strength and structural integrity, rendering it exceptionally resilient and dependable. Industries such as aerospace, automotive, and manufacturing frequently employ stainless steel sheets, as they commonly encounter high temperatures. Furthermore, stainless steel sheets exhibit minimal thermal expansion, ensuring that their shape and dimensions remain intact even when exposed to varying temperatures. Consequently, stainless steel sheets are the preferred choice for applications in which dimensional stability is of utmost importance. All in all, stainless steel sheets are an appropriate alternative for high-temperature applications due to their exceptional heat resistance, durability, and dimensional stability.

- Q: What are the different types of stainless steel sheet finishes for sanitary applications?

- There are several types of stainless steel sheet finishes commonly used for sanitary applications, including #4 brushed finish, #8 mirror finish, and bead blast finish. The #4 brushed finish provides a smooth and uniform appearance with a slight texture, making it resistant to scratches and easy to clean. The #8 mirror finish is highly reflective and has a polished surface, making it aesthetically appealing and suitable for applications where hygiene is crucial. The bead blast finish has a matte texture with a uniform grain, offering a non-reflective surface that is resistant to fingerprints and often used in high-traffic areas.

- Q: Are stainless steel sheets resistant to acids?

- Yes, stainless steel sheets are resistant to acids. Stainless steel is known for its corrosion resistance, and this resistance extends to acids as well. The chromium content in stainless steel forms a protective layer, known as a passive film, that prevents the metal from reacting with acids. This passive film acts as a barrier, making stainless steel sheets highly resistant to a wide range of acids, including both organic and inorganic acids. However, it is important to note that the level of resistance can vary depending on the grade and composition of the stainless steel. Some grades, such as 304 and 316, are particularly resistant to acids, making them suitable for various applications in industries such as chemical processing, food processing, and pharmaceuticals. Nonetheless, even with their resistance to acids, stainless steel sheets may still be susceptible to certain aggressive acids or prolonged exposure to highly corrosive environments. Therefore, it is essential to consult with experts and choose the appropriate grade of stainless steel for specific acid-resistant applications.

- Q: How do I determine the size and dimensions for stainless steel sheets?

- To determine the size and dimensions for stainless steel sheets, you need to consider a few factors. Firstly, think about the specific application or project for which you need the stainless steel sheets. This will help you determine the required size and dimensions based on the purpose and function of the sheets. Next, consider the specific dimensions you need in terms of length, width, and thickness. Stainless steel sheets are typically available in standard sizes, so it's important to know the required measurements beforehand. You can also consult with suppliers or manufacturers who specialize in stainless steel sheets. They can provide guidance and assistance in determining the appropriate size and dimensions based on your specific requirements. Additionally, they may have a range of sizes available in stock that can be tailored to meet your needs. Furthermore, it's crucial to consider any additional factors that may affect the size and dimensions of the stainless steel sheets. This includes factors such as weight restrictions, installation requirements, and compatibility with other components or materials. Overall, determining the size and dimensions for stainless steel sheets requires careful consideration of the application, specific measurements, and consultation with experts in the field.

Send your message to us

0.3-3mm thickness 321 Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords