stainless steel sheets 304L and 316L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel sheet

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steelcoil and stainless steel tube.

A series of pictures

stainless steel sheet

1.Surface:2B/BA/4K/6K/8K

2.Thickness:0.3-3mm

3.Width:1m 1.219m 1.5m

4.Length:1.5m 6m or as your requirement

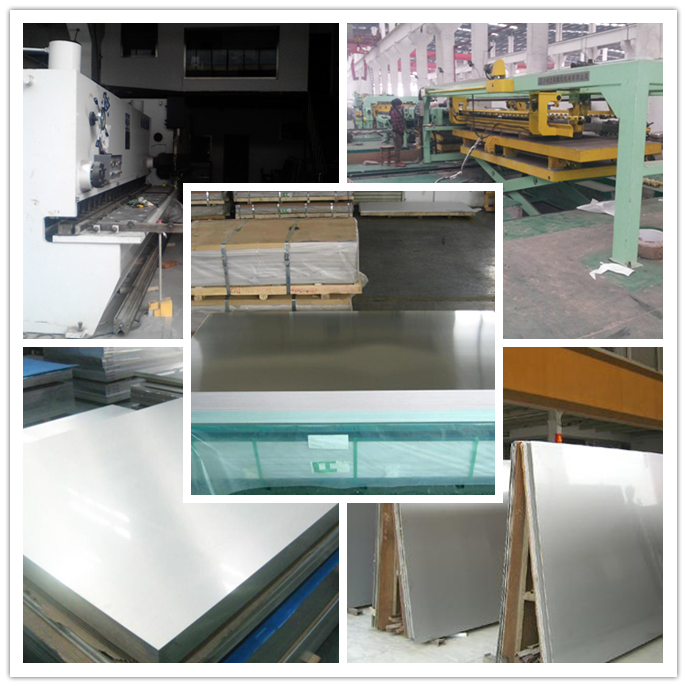

A series of picturs

A series of pictures

A series of pictures

A series of pictures

- Q: How do I prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to keep them clean and free from contaminants. Regularly cleaning the sheets with a mild detergent and water, followed by thorough drying, can help remove any corrosive agents. Additionally, ensuring proper ventilation and avoiding prolonged exposure to high humidity or stagnant conditions can minimize the risk of crevice corrosion. Applying a protective coating or using corrosion inhibitors specifically designed for stainless steel can provide an extra layer of protection against crevice corrosion.

- Q: What does "80 wire" stainless steel plate mean? How much more expensive than the average stainless steel plate?

- It's 0.08mm stainless steel!! It's so thin. It's expensive. A kilo is at least 10 yuan!!

- Q: Are stainless steel sheets non-magnetic?

- No, stainless steel sheets are not non-magnetic.

- Q: What are the different types of stainless steel sheet patterns?

- There are several different types of stainless steel sheet patterns, including plain, diamond, honeycomb, chequered, and linen. These patterns offer various aesthetic options for different applications and design preferences.

- Q: What are the different surface textures available for stainless steel sheets?

- There is a wide range of surface textures available for stainless steel sheets, catering to different aesthetic and functional needs. Let's explore some of the common options: 1. The No. 1 Finish, also known as mill finish, is the most prevalent surface texture. It is achieved through hot rolling and offers a smooth and reflective appearance. 2. The No. 2B Finish, achieved through cold rolling and annealing, has a slightly matte look with a non-reflective finish. 3. The No. 4 Finish, also called brushed or satin finish, is obtained through mechanical polishing. It showcases a brushed appearance with fine parallel lines, providing a textured and decorative touch. 4. The No. 8 Finish, also referred to as mirror or reflective finish, involves polishing the stainless steel sheet to a high shine. It boasts a glossy, mirror-like appearance that reflects light and adds a touch of luxury. 5. The Embossed Finish entails imprinting patterns or designs onto the stainless steel sheet. It can range from simple textures like diamond or linen patterns to more intricate designs, providing visual interest and enhanced grip for specific applications. 6. The Bead Blast Finish is achieved by blasting the stainless steel sheet with fine glass beads or other abrasives. It results in a uniform, matte finish with a slightly roughened texture, suitable for applications where a subdued appearance is desired. 7. The Etched Finish involves chemically etching the stainless steel sheet to create intricate patterns or designs. It offers a unique and artistic finish with detailed textures. These examples represent just a fraction of the diverse surface textures available for stainless steel sheets. Each texture possesses distinct characteristics, enabling a wide range of design possibilities across industries such as architecture, interior design, automotive, and more.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets come in various standard sizes and thicknesses that are widely used in different industries and applications. The standard sizes typically range from 4 feet by 8 feet to 5 feet by 10 feet, although custom sizes can also be obtained based on specific requirements. Regarding thicknesses, stainless steel sheets are available in several standard options, including 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). These thicknesses refer to the nominal thickness, and actual thickness may vary slightly. It is important to note that stainless steel sheets can also be obtained in metric sizes, with common thicknesses ranging from 0.5 mm to 3 mm. This allows for flexibility and compatibility with international standards and specifications. Overall, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements, ensuring wide availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: What are the different types of finishes available for stainless steel sheets?

- Stainless steel sheets come in various finishes, each with its own distinct appearance and level of protection. Some commonly used finishes include: 1. No. 1 Finish: This finish is achieved by hot rolling the stainless steel sheet, resulting in a dull and rough surface that lacks reflection. It is commonly utilized in industrial settings where appearance is not the primary concern. 2. No. 2B Finish: By cold rolling the stainless steel sheet and subsequently annealing it in a controlled atmosphere, a smooth and reflective surface is obtained. This finish is widely favored in applications that require an aesthetically pleasing appearance, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this technique involves applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is often used for architectural and decorative purposes. 4. No. 8 Finish: This highly reflective finish is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is commonly employed in applications that demand a sleek and sophisticated look, such as high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is accomplished by annealing the stainless steel sheet in a controlled atmosphere, followed by pickling or blasting to remove any oxide scale. It results in a smooth and bright surface, making it suitable for applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: By mechanically brushing the surface of the stainless steel sheet with fine abrasive belts, a subtle and textured look is achieved. This finish can be utilized for architectural and decorative purposes. 7. Embossed Finish: This finish entails imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is commonly employed in applications like elevator interiors, wall cladding, and signage. These are just a few examples of the numerous finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The selection of the appropriate finish depends on the specific application and desired appearance.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Yes, stainless steel sheets are highly suitable for food packaging equipment. Stainless steel is a popular choice in the food industry due to its numerous advantageous properties. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. This makes it safe for direct contact with food products. Additionally, stainless steel is resistant to corrosion, rust, and staining, which ensures the durability and longevity of the equipment. It is also easy to clean and sanitize, making it ideal for maintaining high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process. Furthermore, stainless steel has excellent strength and heat resistance properties, allowing it to withstand high temperatures without deforming or compromising its structural integrity. This is particularly important in food packaging equipment where heat sealing or thermal processing is involved. In conclusion, stainless steel sheets are highly suitable for food packaging equipment due to their non-reactive nature, corrosion resistance, ease of cleaning, and high strength. These qualities make stainless steel a reliable and hygienic choice for ensuring the safety and quality of food products during packaging processes.

- Q: Are stainless steel sheets suitable for architectural mesh applications?

- Architectural mesh applications greatly benefit from the use of stainless steel sheets. This material is incredibly versatile and durable, offering a multitude of advantages for architectural purposes. With its resistance to corrosion, stainless steel is indispensable for long-lasting performance in outdoor and high-moisture environments. Moreover, its exceptional strength enables it to withstand heavy loads, making it an ideal choice for structural applications. The utilization of stainless steel sheets in architectural mesh brings together functionality and aesthetics in a unique manner. This mesh can be employed in various ways, such as facades, cladding, sunshades, balustrades, and partitions. It can be woven or welded into diverse patterns and shapes, allowing for imaginative and visually appealing designs. Furthermore, stainless steel architectural mesh provides excellent transparency and airflow, making it suitable for applications requiring ventilation or light transmission. It enhances the visual appeal of a building by creating a sense of openness, while simultaneously ensuring privacy and security. Additionally, stainless steel offers a high level of customization. It can be finished in different colors and surface textures, providing architects and designers with the opportunity to achieve their desired aesthetic. Additionally, stainless steel is a sustainable material, as it is fully recyclable and has a long lifespan, minimizing the environmental impact of architectural projects. In summary, stainless steel sheets are an excellent choice for architectural mesh applications due to their corrosion resistance, strength, versatility, and aesthetic appeal. They grant architects and designers a wide range of possibilities to create visually striking and functional structures.

- Q: How do you prevent intergranular corrosion in stainless steel sheets?

- Intergranular corrosion in stainless steel sheets can be prevented through various methods such as proper selection of stainless steel grade, heat treatment, and appropriate welding techniques. 1. Stainless Steel Grade Selection: Choosing the right stainless steel grade is crucial in preventing intergranular corrosion. Grades with a low carbon content, such as 304L or 316L, are less susceptible to intergranular corrosion compared to higher carbon grades. These low carbon grades minimize the formation of chromium carbide precipitates, which are the main cause of intergranular corrosion. 2. Heat Treatment: Heat treatment processes like solution annealing and quenching can help eliminate or reduce the formation of chromium carbide precipitates. This treatment restores the stainless steel's corrosion resistance by dissolving existing precipitates and promoting the formation of a protective chromium oxide layer on the surface. 3. Welding Techniques: Careful attention must be given to welding stainless steel sheets to prevent intergranular corrosion. Processes like gas tungsten arc welding (GTAW) or laser welding that provide precise control over heat input are preferred. Additionally, using low carbon filler metals or consumables specifically designed for intergranular corrosion resistance can minimize the risk of corrosion. 4. Post-Weld Cleaning and Passivation: After welding, it is essential to thoroughly clean the welded area to remove any contaminants or oxide scales that could promote corrosion. Acid cleaning followed by passivation helps restore the protective oxide layer and enhances the stainless steel's resistance to intergranular corrosion. 5. Avoiding Sensitization: Sensitization occurs when stainless steel is exposed to high temperatures for extended periods, leading to the formation of chromium carbide precipitates. It is crucial to avoid prolonged exposure to temperatures between 450-850°C (842-1562°F) during fabrication or service to prevent sensitization and subsequent intergranular corrosion. By implementing these preventive measures, intergranular corrosion in stainless steel sheets can be effectively minimized, ensuring the longevity and performance of the material in various applications.

Send your message to us

stainless steel sheets 304L and 316L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords