316l 0.8mm Sheet Stainless Steel with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM International Corporation

CNBM International Corporation

Stainless steel

CNBM began to domestic trade since 70S,now we also sell stainless steel aborad.

We are the agent of TISCO,BAOSTEEL,LISCO,JISCO,ZPSS.

Our main products are stainless steel inox sheet/plate,coil/roll,strip,bar,angle,pipe and tube.

Grade-- 201,202,304,304L,316,316L,310S,309S,301,321,904L,410,420,430,409.

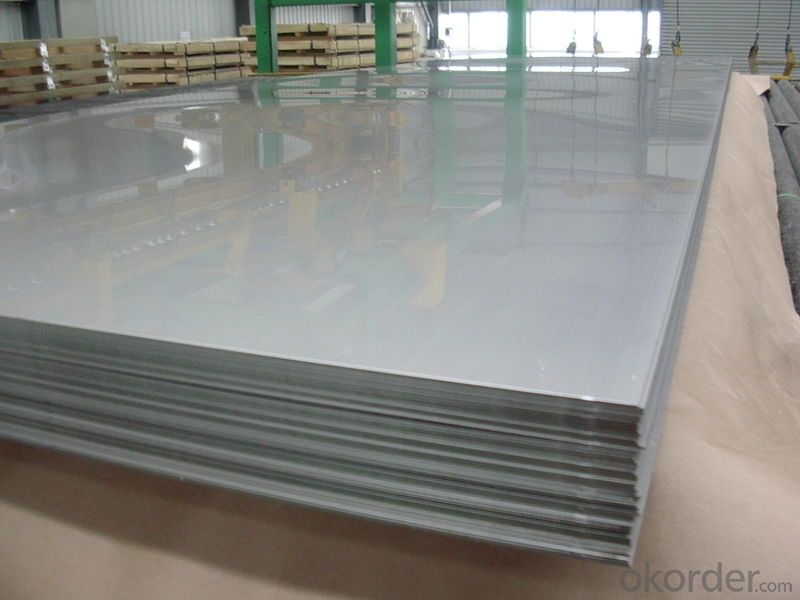

Surface--2B,BA,No.4/HL/Hairline/brushed/satin,8K/No.8/mirror,SB,gold,etch,No.1,polish.

Thickness--0.2-6mm for cold rolled; 3-150mm for hot rolled.

Width:10mm-2000mm for coil.

Standard size --1000×2000mm,1219×2438mm=4ft×8ft=1220×2440mm,

1250×2500mm,1500×3000/6000mm,1524×6096mm.For sheets/plates.

Certificate--ISO,BV,SGS,TUV,IQI or other third inspections.

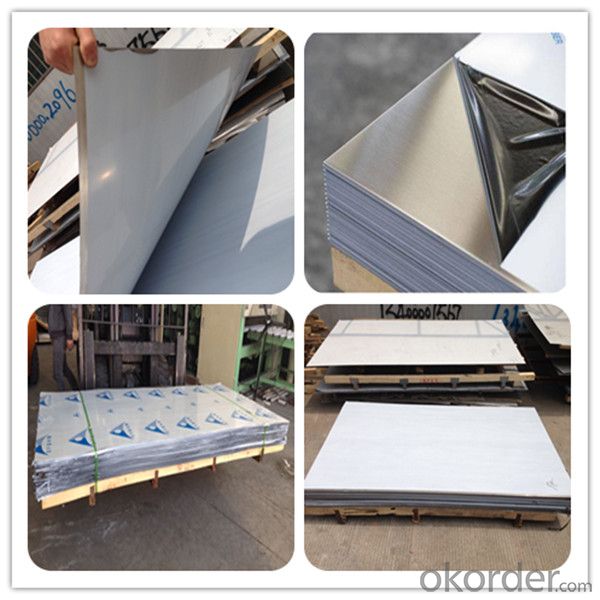

Package--wooden pallets with fimugated,iron pallets,water proof papers,

interleaved paper,pvc film,20'GP or 40'GP container.

Product Description

Description of 316l 0.8mm sheet stainless steel

1 | Product Name | 316l 0.8mm sheet stainless steel |

2 | Material | ASTM 301, ASTM304,ASTM304L, ASTM 316, ASTM316Ti,ASTM309S, ASTM310S, ASTM321, ASTM347H,ASTM A317,ASTMA317L, ASTM409,ASTM409L,ASTM410,ASTM420,ASTM430 ASTM 201,ASTM202, |

3 | Technique | Cold Rolled Stainless Steel plate Cold Drawn Stainless Steel plate Hot Rolled Stainless Steel plate |

4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

5 | Thickness | 0.2-6.0mm for cold rolled 3.0-300mm for hot rolled |

Width | 600-3000mm | |

Length | Any, as your requirement | |

6 | Surface Treatment | No.1, NO.4 ,2B, BA, Hair Line,8K,Brush,Embossed and Mirror Finish or as your demand |

7 | Packing | Standard export packing-For stainless steel sheet 1.surface polish 2. bundle package 3. wooden case , wooden pallet package 4:container or bulk 5. special according to customer request |

8 | Delivery | Normally according to the order quantity or upon negotiation |

9 | Price Item | FOB,CFR,CIF Or as negotiated |

10

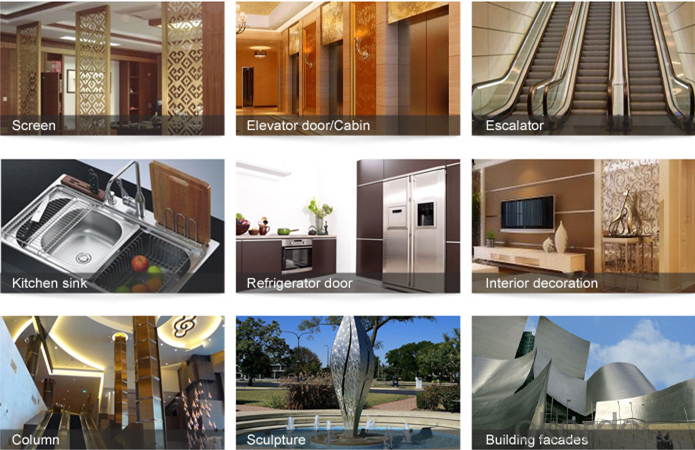

| Application | Stainless Steel plate are widely used in below fields: 1: Construction feild,shipping building industry 2: Petroleum and Chemical Industries 3: Food and Machenical Industries 4: Boiler Heat Exchange 5: Machinery and Hardware Industries |

Production of Wuxi 316l stainless steel price per ton

Mechanical property of 316l 0.8mm sheet stainless steel

| Tensile Strength | σb (MPa)≥520 |

| Offset Yield Strength | σ0.2 (MPa)≥205 |

| Elongation | δ5 (%)≥40 |

| Hardness | ≤187HB;≤90HRB;≤200HV |

| Density(20℃,g/cm3) | 7.98 |

Chemical composition of 316l 0.8mm sheet stainless steel

| 316 | C | Si | Mn | P | S | Ni | Cr | Mo |

| % | ≤0.08 | ≤1 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.00-3.00 |

Maintenance of 316l 0.8mm sheet stainless steel

Regular cleaning and maintenance

Pay attention to prevent the occurrence of the phenomenon of surface scratches

Use soap, weak detergent or warm water to remove surface dust, dirt

In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

Use neutral detergent or ammonia solution in addition to surface oil

With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packaging & Shipping

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

After-sale service:

CNBM provides the services and support you need for every step of our cooperation.

We’re the business partners you can trust; you can relax and get on with doing business.

For any problem, please kindly contact us at any your convenient time,

we’ll reply you in our first priority within 24 hours

Application

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different types of stainless steel sheet surface treatments available?

- There is a wide range of surface treatments available for stainless steel sheets, each with its own distinct benefits and appearances. Some of the most commonly used treatments are: 1. No.1 Finish: This finish is ideal for industrial purposes and is achieved through hot-rolling, annealing, and pickling. It has a rough texture with visible grain lines. 2. No.2B Finish: Also known as a bright, cold-rolled finish, this treatment provides a smooth and reflective surface with a moderate level of gloss. It is obtained through annealing and pickling. 3. No.3 Finish: By using progressively finer abrasive materials, a finely polished surface is achieved. It has a semi-reflective appearance and is often used for decorative applications. 4. No.4 Finish: Similar to the No.3 finish, but with a higher level of polish, this treatment gives the stainless steel sheet a satin-like appearance. It is commonly used in architectural and kitchen equipment applications. 5. BA (Bright Annealed) Finish: This treatment results in a mirror-like, highly reflective finish. It is achieved by annealing the stainless steel sheet in a controlled atmosphere and is often used for decorative purposes and in the production of household appliances. 6. Embossed Finish: This treatment involves stamping a pattern onto the stainless steel sheet to create a textured surface. It is frequently used for decorative purposes or to enhance grip on surfaces. 7. Colored Finish: Stainless steel sheets can also be treated with various colored coatings, such as gold, black, or bronze. These finishes are achieved through processes like PVD (Physical Vapor Deposition) or electroplating. Each surface treatment offers its own advantages and is suitable for specific applications. When selecting the appropriate treatment for a stainless steel sheet, it is important to consider factors such as durability, corrosion resistance, aesthetic appeal, and intended use.

- Q: Are stainless steel sheets suitable for outdoor sculptures?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures. Stainless steel is a durable and corrosion-resistant material, making it ideal for withstanding harsh outdoor conditions. It is resistant to rust, staining, and fading, making it a low-maintenance choice for outdoor sculptures. Additionally, stainless steel has a sleek and modern appearance, which can enhance the aesthetic appeal of outdoor artworks. Its strength and malleability also make it suitable for creating intricate and detailed sculptures. Therefore, stainless steel sheets are an excellent choice for outdoor sculptures, ensuring longevity and enhancing their visual impact.

- Q: Can stainless steel sheets be cold rolled?

- Indeed, it is possible to cold roll stainless steel sheets. The cold rolling process involves passing a stainless steel sheet through a sequence of rollers at ambient temperature, leading to a decrease in thickness and an augmentation in both hardness and strength. By employing this technique, one can create stainless steel sheets with accurate measurements and impeccable surface textures. Cold rolling is widely utilized in the production of stainless steel sheets, catering to diverse sectors including automotive parts, kitchen devices, and architectural constructions.

- Q: What are the different types of stainless steel sheet patterns?

- There are several different types of stainless steel sheet patterns available. Some of the most common patterns include: 1. Plain or smooth pattern: This is the most basic and simple pattern, with a smooth and flat surface. 2. Diamond pattern: Also known as tread plate or checker plate, this pattern features raised diamond-shaped ridges, providing excellent slip resistance. 3. Tear drop pattern: Similar to the diamond pattern, this pattern features raised teardrop-shaped ridges, offering enhanced slip resistance. 4. Linen pattern: This pattern resembles the texture of linen fabric, with a series of parallel lines intersected by a crisscross pattern. 5. Quilted pattern: This pattern resembles a quilted fabric, with a diamond-shaped or square-shaped design. 6. Hammered pattern: This pattern has a textured surface that resembles the marks left by a hammer, adding visual interest and dimension. 7. Perforated pattern: This pattern features small holes or perforations in the sheet, allowing for improved ventilation and drainage in certain applications. These are just a few examples of the various stainless steel sheet patterns available. Different patterns offer different aesthetic and functional benefits, allowing for greater versatility in design and application.

- Q: Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Stainless steel is a type of metal alloy that contains a high percentage of chromium, which forms a protective layer of chromium oxide on the surface when exposed to air or moisture. This chromium oxide layer acts as a barrier, preventing oxygen from reaching the underlying metal and thus making stainless steel highly resistant to corrosion and fire. Stainless steel sheets have a melting point of around 2750°F (1510°C), which is significantly higher than the temperatures typically encountered in most fire scenarios. This means that stainless steel can withstand intense heat for a prolonged period without deforming or losing its structural integrity. Furthermore, stainless steel is non-combustible and does not contribute to the spread of flames. It does not release harmful gases or toxic fumes when exposed to fire, making it a safe material for use in various applications where fire resistance is crucial, such as in building construction, industrial equipment, and transportation. Due to these properties, stainless steel sheets are widely used in fire-rated structures, including fire doors, fire-rated walls, and fire-resistant enclosures. They provide an effective barrier against the heat and flames, helping to contain the fire and protect the surrounding areas. However, it is important to note that while stainless steel is highly resistant to fire, it can still be affected by extremely high temperatures or prolonged exposure to fire. In such cases, the material may experience some degree of distortion or damage. Therefore, it is essential to consider the specific fire rating requirements and consult with experts to ensure the appropriate selection and installation of stainless steel sheets in fire-resistant applications.

- Q: Can stainless steel sheets be used for magnetic shielding?

- To a certain extent, stainless steel sheets can be utilized for magnetic shielding. Although stainless steel is not intrinsically magnetic, it possesses some magnetic properties due to the presence of iron, a magnetic material, in stainless steel alloys. This enables stainless steel sheets to exhibit weak magnetic characteristics. Nevertheless, the magnetic shielding capabilities of stainless steel sheets are limited when compared to materials specifically engineered for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more efficiently than stainless steel. However, stainless steel sheets can still offer some level of magnetic shielding, particularly in environments with lower intensity magnetic fields. They can assist in reducing the transmission of magnetic fields from one area to another, which can be beneficial in certain applications. Nonetheless, for situations that require high-intensity or sensitive magnetic shielding, it is recommended to utilize specialized magnetic shielding materials for optimal effectiveness.

- Q: What are the different types of perforated patterns available for stainless steel sheets?

- Stainless steel sheets come in a variety of perforated patterns, each serving specific purposes and meeting different aesthetic preferences. Let's explore some commonly used patterns: 1. The round hole pattern is the most widely used and basic design. It consists of evenly spaced round holes that allow for excellent airflow and drainage. It finds its applications in industrial filtration systems or as decorative panels. 2. The square hole pattern, similar to the round hole pattern, offers a more geometric and uniform appearance. It is often preferred for architectural and decorative purposes, providing a modern and sleek look. 3. The slotted hole pattern consists of elongated and rectangular holes, allowing for more flexibility in terms of airflow and visibility. It is commonly used in grills or air ventilation systems where better drainage or a higher open area is required. 4. The hexagonal hole pattern offers a unique and visually appealing design. It provides excellent strength and structural integrity, making it suitable for applications requiring durability, such as safety barriers or machine guards. 5. In addition to the standard patterns, there are various decorative hole patterns available for stainless steel sheets. These patterns feature intricate designs or shapes, adding an artistic touch to architectural and interior design applications. When selecting a perforated pattern for stainless steel sheets, it is important to consider the specific requirements of your project, such as airflow, visibility, drainage, or aesthetic appeal. Consulting with a supplier or expert in the field can help you make an informed decision based on your needs.

- Q: Are stainless steel sheets suitable for railway applications?

- Stainless steel sheets prove to be a fitting option for railway applications. They possess exceptional resistance to corrosion, rendering them perfect for utilization in settings constantly exposed to moisture, chemicals, and other harsh circumstances, such as railway tracks. Furthermore, these sheets exhibit notable strength and durability, essential qualities for enduring heavy loads and vibrations associated with railway operations. The material also showcases commendable heat resistance, enabling it to maintain its structural integrity even in high-temperature environments like railway brakes. Moreover, stainless steel sheets can be effortlessly molded and fabricated into diverse shapes and sizes, making them adaptable for various railway components such as cladding, paneling, and structural elements. All in all, stainless steel sheets offer a dependable and enduring solution for railway applications, ensuring the safety and performance of railway infrastructure.

- Q: What is the maximum thickness available for stainless steel sheets?

- The maximum thickness available for stainless steel sheets can vary depending on the specific grade and type of stainless steel, but it generally ranges from 0.5 to 6 millimeters (mm) or even thicker for certain applications.

- Q: How do you prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, you can implement a few preventive measures such as keeping the sheets clean and dry, avoiding exposure to corrosive substances, applying a protective coating or passivation treatment, and ensuring proper ventilation to minimize moisture buildup.

Send your message to us

316l 0.8mm Sheet Stainless Steel with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords