Sbx12 Geogrid

Sbx12 Geogrid Related Searches

Sbx 11 Geogrid Bx 1200 Geogrid Tensar Bx 1200 Geogrid Rx1200 Geogrid Biaxial Geogrid Bx1200 Tensar Bx1200 Geogrid Tensar Bx1200 Biaxial Geogrid Rx 1100 Geogrid Geogrid Bx1100 Bx1200 Geogrid Specification Tensar Ux Geogrid 3xt Geogrid Tensar Biaxial Geogrid Bx1200 Biaxial Geogrid Bx1100 Triax Geogrid Tenax Geogrid 5xt Geogrid Tensar Bx1100 Geogrid Tensar Bx1100 Biaxial Geogrid Sg200 Geogrid Tensar Ss30 Geogrid Geogrid Triax Plaxis Geogrid Gmb Geogrid Sgu 60 Geogrid Bidirectional Geogrid Srw 3 Series Geogrid Uniaxial Geogrid Honeycomb Geogrid Interax GeogridSbx12 Geogrid Supplier & Manufacturer from China

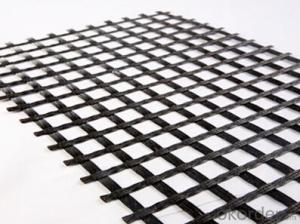

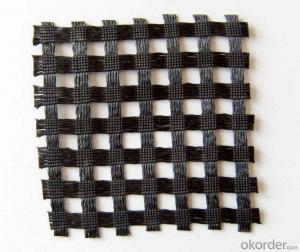

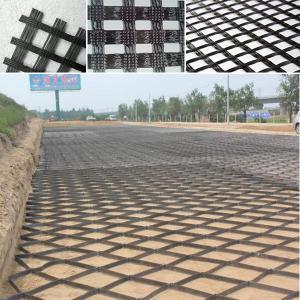

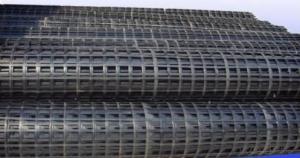

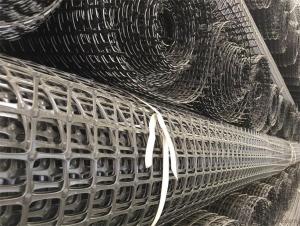

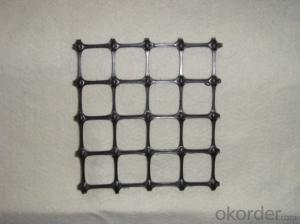

SBX12 Geogrid is a high-performance geosynthetic product designed for soil reinforcement and stabilization in various civil engineering applications. This geogrid is made from high-density polyethylene (HDPE) and features a unique structure that provides excellent tensile strength and durability. It is widely used in applications such as road construction, slope protection, and soil reinforcement, making it a versatile solution for a range of civil engineering challenges.The SBX12 Geogrid is particularly effective in enhancing the load-bearing capacity of soil, reducing the risk of subsidence, and improving overall stability. Its usage scenarios include the reinforcement of road bases, embankments, and retaining walls, as well as in the construction of tunnels and other underground structures. This product's ability to distribute loads evenly and prevent soil movement makes it an essential component in many construction projects, ensuring both safety and efficiency.

Okorder.com is a leading wholesale supplier of SBX12 Geogrid, offering a large inventory of this high-quality geosynthetic material. With a commitment to providing top-tier products at competitive prices, Okorder.com ensures that customers have access to the SBX12 Geogrid they need for their projects. This extensive inventory allows for quick turnaround times and the ability to meet the demands of various construction and engineering applications.

Hot Products