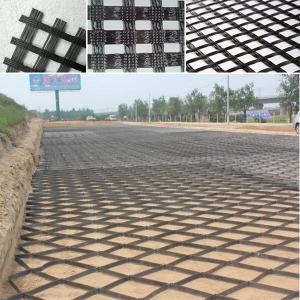

High Strength PP Biaxial Geogrid for Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

CMAX Biaxial geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching,

heating, longitudinal stretching and transverse stretching.

Performance:

Homogeneous structure, low creep, anti-aging and resisting acid and alkaline.

Applications:

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and

roadway in the coal mine.

Packing

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

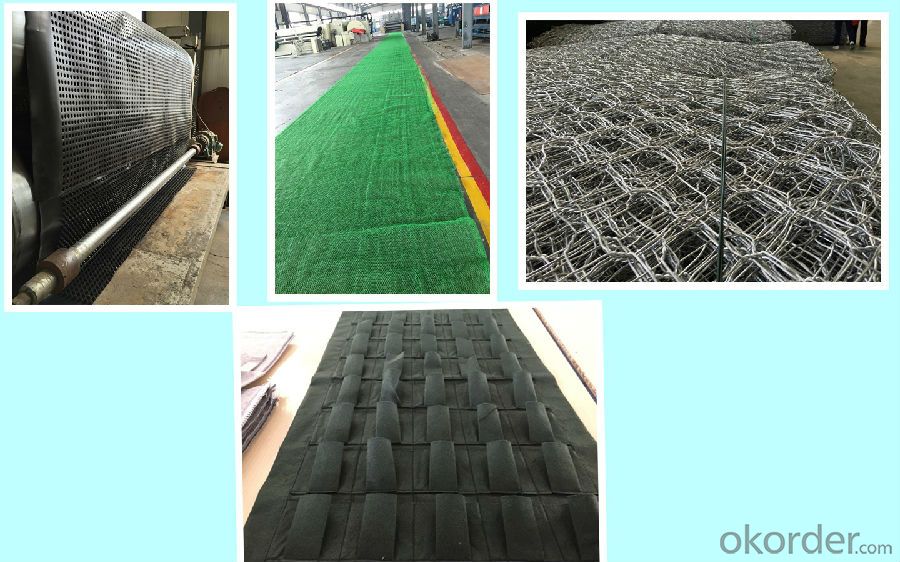

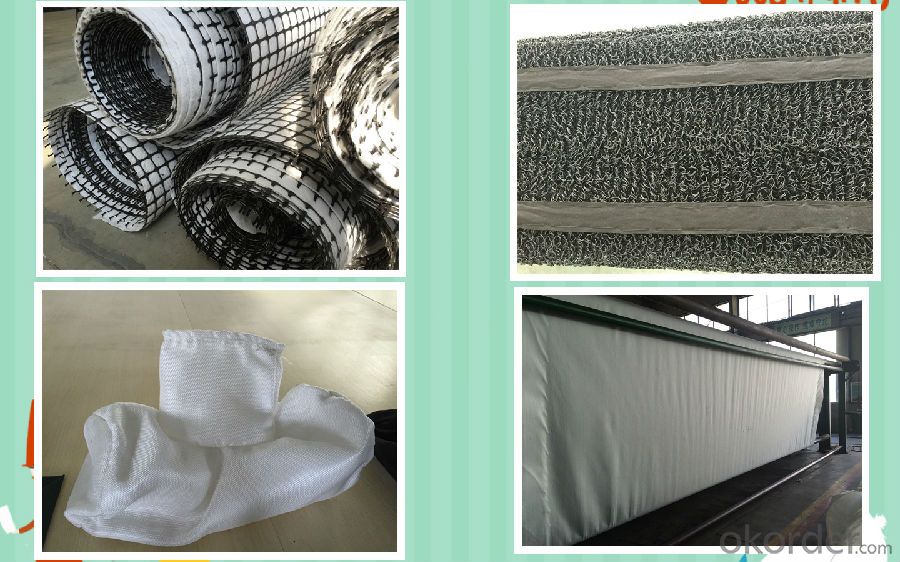

●Do you have other products?

Yes, we have, please check the pictures:

- Q: Can geogrids be used in reinforcement of bridge abutments on expansive soils?

- Yes, geogrids can be used in the reinforcement of bridge abutments on expansive soils. Geogrids are commonly used in civil engineering projects to provide reinforcement and stability to soil structures, including bridge abutments. They help to distribute loads and reduce the potential for soil movement and settlement, particularly in areas with expansive soils that are prone to swelling and shrinking. By incorporating geogrids into the design and construction of bridge abutments, the risk of damage and failure caused by expansive soils can be minimized, ensuring the longevity and safety of the structure.

- Q: Can geogrids be used for reinforcement in soft soils?

- Yes, geogrids can be used for reinforcement in soft soils. Geogrids are designed to provide stability and improve the load-bearing capacity of soils, including soft soils. They can be installed to distribute and restrain the forces exerted on the soil, preventing excessive settlement and improving overall performance.

- Q: Are geogrids suitable for stabilizing soft soils?

- Yes, geogrids are suitable for stabilizing soft soils. Geogrids are designed to provide reinforcement and improve the strength and stability of soil, especially in areas with soft or weak soils. By increasing soil stiffness and redistributing loads, geogrids help to prevent soil settlement, improve bearing capacity, and enhance overall stability.

- Q: Can geogrids be used in reinforcement of gabion structures?

- Yes, geogrids can be used in the reinforcement of gabion structures. Geogrids are commonly used to provide stability and enhance the strength of gabion walls by improving load distribution and reducing soil movement. They are typically installed horizontally within the gabion structure to increase its overall stability and prevent deformation.

- Q: What is the difference between polyethylene geogrid and uni directional high strength geogrid

- The utility model has the advantages of convenient operation, time saving, labor saving, short construction period and reduced maintenance cost. FourThe utility model relates to a bidirectional grid which is suitable for preventing cracks in culvert. FiveTwo way grid is used to enhance soil slope and prevent soil erosion. Six

- Q: Are geogrids suitable for reinforcing landfill liners?

- Yes, geogrids are suitable for reinforcing landfill liners. These high-strength materials can enhance the stability and integrity of the liner system by providing additional reinforcement and preventing soil erosion. Geogrids also improve the overall performance and longevity of landfill liners, making them a reliable choice for reinforcing purposes.

- Q: How do geogrids improve the stability of mechanically stabilized earth walls?

- Geogrids improve the stability of mechanically stabilized earth walls by enhancing the soil's tensile strength and preventing lateral movement. They act as a reinforcement, distributing the applied loads more evenly throughout the structure and reducing the potential for wall failure. Additionally, geogrids increase the frictional resistance between the soil and the wall, effectively increasing the overall stability and performance of the structure.

- Q: Are geogrids resistant to fire?

- No, geogrids are not typically resistant to fire. They are primarily used for soil stabilization and reinforcement purposes and do not possess inherent fire-resistant properties.

- Q: High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester polyester geogrid.Turn left and turn right |

- Q: What are the long-term performance characteristics of geogrids?

- The long-term performance characteristics of geogrids include excellent resistance to chemical and biological degradation, high tensile strength, stability, and durability. Geogrids are designed to provide long-lasting reinforcement to soil structures, retaining walls, and roadways, maintaining their effectiveness and integrity over many years of use.

Send your message to us

High Strength PP Biaxial Geogrid for Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords