Polyester Geogrid for Road Construction with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid Description

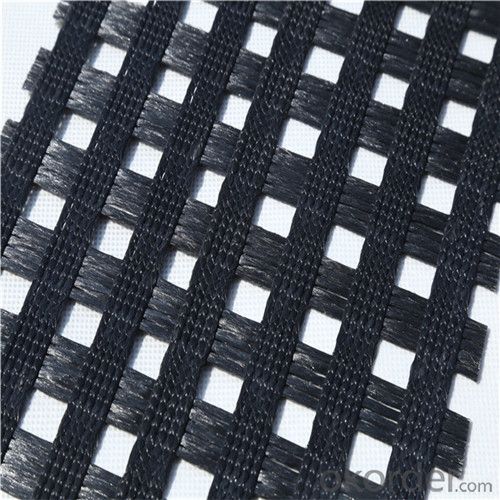

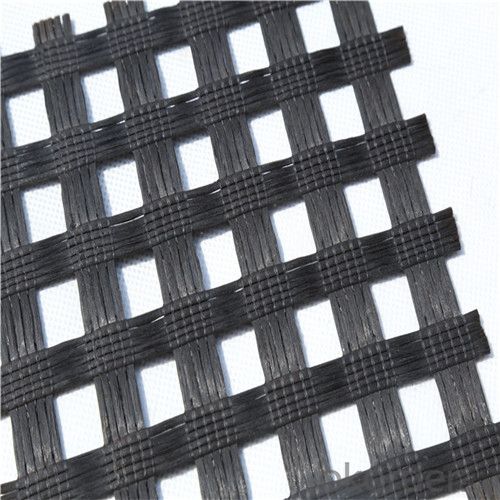

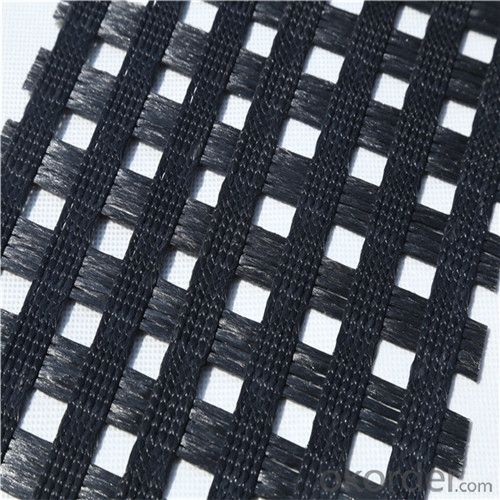

Polyester Geogrid chooses polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending between warp and weft direction.

Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction, then it forms into a mesh size product after coated with high quality oil-soluble PVC.

Polyester Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN, 150-150KN, 200-200KN,

Roll Size: 3.95x100m, as request,

Polyester Geogrid Property

1) High tensile strength

2) Low elongation

3) Anti-erosion, anti-aging

4) Good affinity with base material

5) Light weight, water drainage

Polyester Geogrid Application

1) Roadbed reinforcement in highway, railway and municipal road.

2) Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

3) Roadbed slope reinforcement, retaining wall reinforcement.

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q: Can geogrids be used in reinforcement of concrete structures?

- Yes, geogrids can be used in the reinforcement of concrete structures. Geogrids are commonly used as a reinforcing material in civil engineering projects, including the reinforcement of concrete structures such as retaining walls, bridge abutments, and road pavements. They help to distribute and enhance the load-bearing capacity of the concrete, improve its stability, and reduce the risk of cracking or structural failure.

- Q: The difference between polyester glass fiber cloth and glass geogrid

- Hello, this is two different products

- Q: What are the advantages of using geogrids in ground improvement for seismic stability?

- Geogrids offer several advantages when used in ground improvement for seismic stability. Firstly, they provide reinforcement to the soil, improving its tensile strength and reducing the risk of soil liquefaction during an earthquake. This helps to prevent ground failure and ensures the stability of structures built on the improved ground. Additionally, geogrids can enhance the overall bearing capacity of the soil, allowing it to withstand the dynamic forces exerted during seismic events. Furthermore, these geosynthetic materials are easy to install, cost-effective, and have a long lifespan, making them a practical choice for seismic ground improvement projects.

- Q: How do geogrids help in reducing soil compaction?

- Geogrids help in reducing soil compaction by distributing the load from traffic or construction equipment more evenly across the soil surface. This helps to minimize the concentration of pressure on specific areas, preventing excessive compaction and allowing for better soil structure and drainage.

- Q: How do geogrids improve the performance of geotextile erosion control blankets?

- Geogrids improve the performance of geotextile erosion control blankets by providing additional reinforcement and stability to the blanket. They enhance the tensile strength and load-bearing capacity of the geotextile, preventing excessive soil erosion and improving overall erosion control effectiveness.

- Q: Can geogrids be used in retaining walls for waterfront applications?

- Yes, geogrids can be used in retaining walls for waterfront applications. Geogrids are commonly used in retaining walls to provide stability and reinforcement. In waterfront applications, where there is a higher risk of erosion and soil movement, geogrids can help prevent the retaining wall from shifting or collapsing. They can also enhance the overall durability and strength of the wall, making it suitable for waterfront environments.

- Q: What is the market price of the geotechnical grid in 2017

- (1) the first accurate release of subgrade slope line, in order to ensure the roadbed width of each side of the widened 0.5m, soil drying good leveling by 25T after vibroll pressure two times, then 50T shock pressure of four times, how much is the uneven supply market price? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong local earthwork grid with artificial coordination.

- Q: How do geogrids improve the performance of geocell-reinforced retaining walls?

- Geogrids enhance the performance of geocell-reinforced retaining walls by providing additional tensile strength and stability. They act as a reinforcement layer within the geocell structure, preventing soil movement and enhancing load distribution. This combination increases the overall strength of the retaining wall, allowing it to withstand higher loads and maintain structural integrity over time.

- Q: Are there any environmental concerns associated with geogrids?

- Yes, there are a few environmental concerns associated with geogrids. The production of geogrids involves the use of non-renewable resources and energy, which contributes to carbon emissions and environmental degradation. Additionally, the disposal of geogrids after their useful life can pose challenges as they are often not biodegradable and may end up in landfills. However, when used properly and managed responsibly, geogrids can still provide environmental benefits such as erosion control and soil stabilization.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are typically made from high-strength materials such as polyester or polypropylene, which are resistant to degradation caused by UV exposure, chemical exposure, and biological factors. Geogrids also have high tensile strength, allowing them to withstand heavy loads and maintain their structural integrity over time. Additionally, they have low creep and deformation rates, meaning they can maintain their original shape and performance for an extended period. Overall, geogrids have proven to be highly durable and reliable for various applications in civil engineering and construction.

Send your message to us

Polyester Geogrid for Road Construction with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords