Tenax TT Geogrids for Construction and Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction

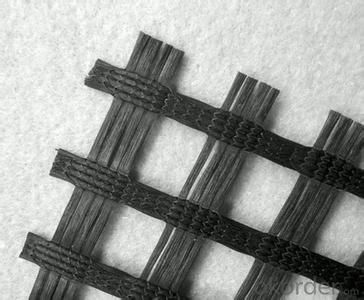

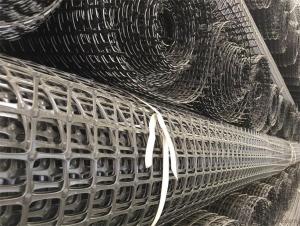

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance

Fiberglass Geogrid Features :

1. Fiberglass geogrid for soil reinforcement

2. Pavement subgrade stabilization

3. Area /Ground stabilization

4. Pavement base reinforcement

5. Working & load transfer platforms

6. Rail Track-bed stabilization

7. Reinforced granular foundation beds

PROPERTIES

1. High tensile strength in both the warp and weft directions;

2. Low elongation;

3. Excellent temperature range;

4. Good anti-age and alkali-resistance;

5. Reduce construction cost, extend service life of road and prevent deflection cracks.

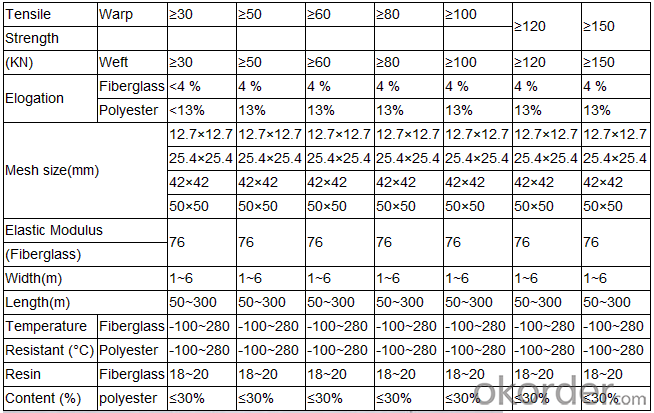

Fiberglass Geogrid Specification:

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: What are the countries of China's anti dumping

- 1) flat field: laying 50cm thick sandstone gravel or sand and gravel cushion compaction (egg) is conducive to increase frictional resistance between soil and geogrid to base consolidation 2) should pay attention to the connection between laying grille grille and vertical grille grille straight smooth laying according to the design position along the road to base

- Q: How do geogrids improve the performance of mechanically stabilized slopes in high rainfall areas?

- Geogrids enhance the performance of mechanically stabilized slopes in high rainfall areas by providing additional strength and stability to the soil. They act as a reinforcement material, effectively distributing the load and reducing the potential for slope failure. Additionally, geogrids prevent soil erosion by minimizing surface runoff and facilitating water drainage, thus preserving the integrity of the slope even during heavy rainfall events.

- Q: What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q: Are geogrids suitable for use in soil reinforcement for pipeline river crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline river crossings. Geogrids offer excellent soil stabilization and reinforcement properties, providing enhanced tensile strength and load-bearing capacity. They are particularly effective in areas with challenging soil conditions or high water flow rates. Geogrids can effectively distribute the loads from the pipeline, prevent soil erosion, and ensure long-term stability, making them a reliable choice for reinforcing soil in pipeline river crossings.

- Q: What are the types of geogrid, respectively, what role?

- Glass fiber grille is made of high quality enhanced E-glass fiber yarn, woven into the substrate with the foreign advanced warp knitting, warp knitting with directional structure, make full use of the fabric yarn strength, improve its mechanical properties, so it has good tensile strength, tensile strength and creep resistance, planar network shaped material and high quality modified asphalt a coating treatment. The following similar compatibility principle, highlighted with the composite performance of asphalt mixture, and fully protect the glass substrate, which greatly improves the wear resistance and anti shearing ability of the substrate, which can be used to enhance the resistance, cracks, rutting of highway asphalt pavement, the end of the problem is difficult to increase the.

- Q: Can geogrids be used in retaining walls for waterfront parks?

- Yes, geogrids can be used in retaining walls for waterfront parks. Geogrids are commonly used in retaining wall construction as they provide reinforcement and stability to the soil. In the case of waterfront parks, where the retaining walls are exposed to water and potential erosion, geogrids can help prevent soil movement, maintain the integrity of the wall, and enhance its overall durability.

- Q: What are the factors that affect the installation and survivability of geogrids in cold climates?

- The factors that affect the installation and survivability of geogrids in cold climates include the ground temperature, frost heave, freeze-thaw cycles, and the type of soil. Cold temperatures can make the installation process challenging as the ground may become frozen, requiring additional measures to thaw the soil for proper installation. Frost heave, which occurs when water in the soil freezes and expands, can impact the stability and effectiveness of geogrids. Freeze-thaw cycles can also cause damage to the geogrids over time. Additionally, the type of soil, particularly its moisture content and drainage characteristics, can influence the performance and durability of geogrids in cold climates.

- Q: What is the effect of strain rate on geogrid behavior?

- The strain rate has a significant effect on geogrid behavior. At higher strain rates, the geogrid's resistance to deformation and its load-bearing capacity tend to increase. This is due to the geogrid's ability to dissipate energy more effectively at higher strain rates. Conversely, at lower strain rates, the geogrid may exhibit reduced load-bearing capacity and increased susceptibility to deformation. Therefore, the strain rate should be considered when designing and analyzing geogrid applications to ensure their optimal performance.

- Q: What are the factors that affect the installation time of geogrids?

- There are several factors that can affect the installation time of geogrids. First and foremost, the size and complexity of the project play a significant role. Larger and more complex projects may require more time for planning, preparation, and execution. The type and condition of the soil also impact installation time. Soft or loose soils may require additional stabilization measures before the geogrids can be installed, which can extend the overall installation duration. Similarly, rocky or hard soils may require specialized equipment or techniques, which can also increase the installation time. The availability and accessibility of the site can also affect installation time. If the site is difficult to reach or has limited space for equipment and materials, it can slow down the installation process. Additionally, factors such as weather conditions, environmental restrictions, and safety considerations can further influence the installation time. Lastly, the experience and expertise of the installation team can greatly impact the efficiency and speed of the installation process. A skilled and experienced team can streamline the installation and overcome any challenges more effectively, reducing the overall installation time.

- Q: What are the design considerations for geogrids in reinforced soil slopes?

- Some design considerations for geogrids in reinforced soil slopes include the type and strength of the geogrid material, proper installation techniques, adequate spacing and orientation of the geogrid layers, and the required length and width of the geogrid reinforcement. Additionally, factors such as the soil properties, slope geometry, and anticipated loads must be considered to ensure the geogrids can effectively stabilize the slope and prevent soil erosion or failure.

Send your message to us

Tenax TT Geogrids for Construction and Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords