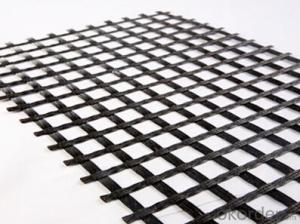

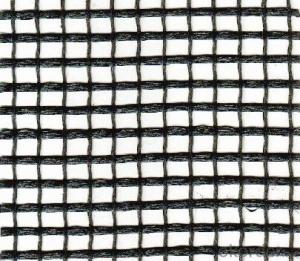

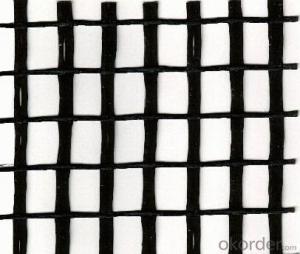

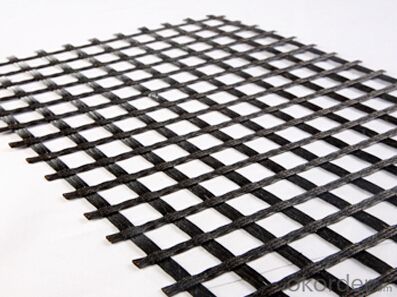

Tenax Fiberglass Geogrid for Earth Work Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

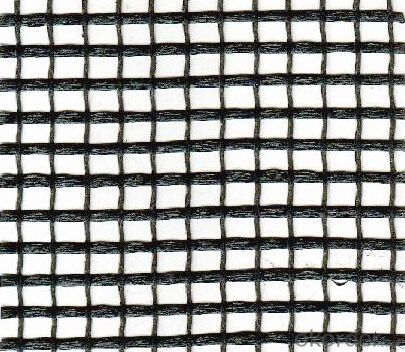

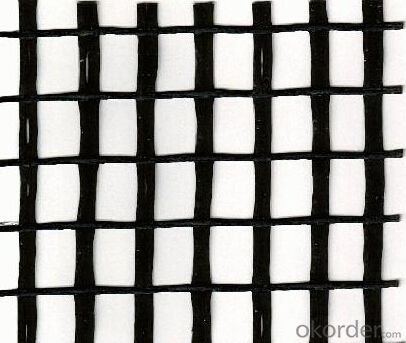

Fiberglass Geogrid for Earth Work Material

Description Of Fiberglass Geogrid for Earth Work Material:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid for Earth Work Material:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid for Earth Work Material:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid for Earth Work Material:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

IMages of Fiberglass Geogrid for Earth Work Material:

FAQ of Fiberglass Geogrid for Earth Work Material:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids help in reducing soil erosion on slopes?

- Geogrids help in reducing soil erosion on slopes by providing reinforcement and stability to the soil. They are placed within the soil and act as a support system, preventing the movement of soil particles downhill. This reinforcement helps to distribute the loads and stresses evenly, reducing the risk of soil erosion caused by water flow or gravity. Additionally, geogrids increase the shear strength of the soil, making it more resistant to erosion and slope failures.

- Q: Are geogrids suitable for use in high water table areas?

- Yes, geogrids are suitable for use in high water table areas. Geogrids are designed to provide reinforcement and stability to soil, making them effective in areas with high water tables. They help distribute the load and prevent soil erosion, making them a suitable solution for such conditions.

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- . That is to say, the permeability coefficient of geosynthetics is broad. The vertical permeability coefficient is unique to geotextiles. The test methods of permeability coefficient and vertical permeability coefficient are similar.

- Q: Can geogrids be used for reinforcement in embankments and dams?

- Yes, geogrids can be used for reinforcement in embankments and dams. Geogrids are high-strength synthetic materials that are commonly used in civil engineering and construction projects to increase the stability and strength of soil structures. By incorporating geogrids into embankments and dams, they can effectively reinforce the soil, reduce settlement, and improve overall performance and durability of these structures.

- Q: What is the tensile strength of a geogrid?

- The tensile strength of a geogrid refers to its ability to resist stretching or breaking under tension or pulling forces. It is typically measured in units of force per unit of cross-sectional area, such as pounds per square inch (psi) or kilonewtons per square meter (kN/m²). The specific tensile strength of a geogrid can vary depending on its material composition, design, and manufacturing process.

- Q: Can geogrids be used in stormwater management?

- Yes, geogrids can be used in stormwater management. They are commonly used to reinforce and stabilize soil, preventing erosion and promoting water infiltration. Geogrids can be installed in various stormwater management systems, such as permeable pavements, retention ponds, and bioswales, to improve their effectiveness and durability.

- Q: Can geogrids be used in streambank stabilization applications?

- Yes, geogrids can be used in streambank stabilization applications. Geogrids are commonly used in these applications to reinforce and stabilize slopes and banks, preventing erosion and soil movement. They provide strength and support to the soil, allowing vegetation to establish and grow, further enhancing the stability of the streambank.

- Q: Geogrid is mainly used for what?

- Application of unidirectional geogrid:Unidirectional geogrid is a kind of high strength structural material, which is suitable for highway, municipal road, railway, runway and so on. 1, strengthen the embankment, can effectively improve the load distribution, and the bearing capacity and service life of the subgrade stability; 2, preventing the material loss caused by the deformation of subgrade, and even rupture; 3, can withstand greater load; 4, applicable to all kinds of soil, no place to be drawn, saves time and labor; and the use of construction simple biaxial geogrid:

- Q: Geotextiles and geogrids to do the re inspection approach?

- If necessary, geotextile and geogrid materials are qualified. But it depends on the situation.

- Q: What are the installation guidelines for geogrids?

- The installation guidelines for geogrids typically include steps such as preparing the subgrade, ensuring proper compaction, rolling out the geogrid, anchoring it securely, and overlapping or connecting multiple rolls as necessary. It is important to follow the manufacturer's instructions and consult with an engineer or specialist to ensure correct installation and maximize the effectiveness of the geogrids.

Send your message to us

Tenax Fiberglass Geogrid for Earth Work Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords