Tenax Tt Uniaxial Unbiaxial Triaxial Plastic Geogrid with Bitumen Coated Black

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

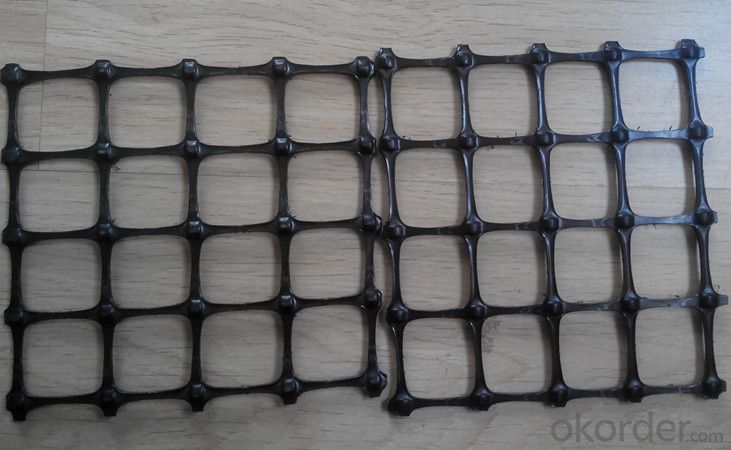

Groupeve Plastic Geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching, including HDPE Geogrid, PP Geogrid. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features

Increase the bearing capacity of the roadbed and foundation and prolong their service life.

Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

Prevent culverts from flawing.

Enhance earth slope and prevent water loss and soil erosion.

Decrease under layer thickness and save manufacturing cost.

Enhance the stability of side slope turf net patch to improve greening.

Replace wire netting used in mine as intermediate ceiling netting.

It is of fire-retardant and anti-static

Applications

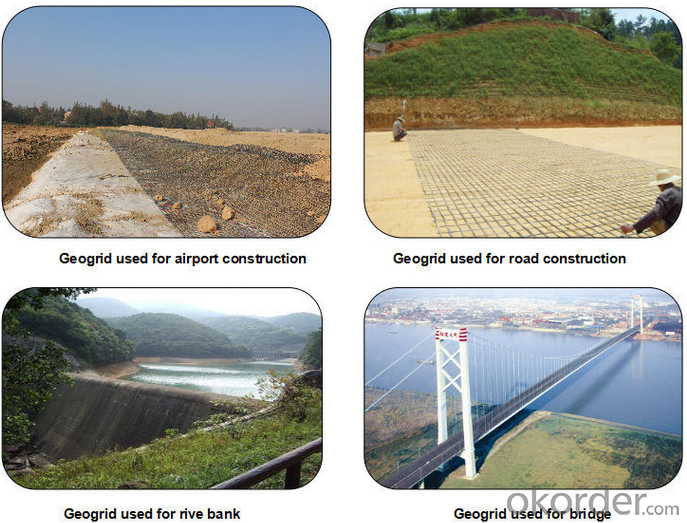

Plastic geogrids can be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks, and ground which cargo lays on and their main usage are as follows:

1. Enhance the bearing capacity of road foundation and extend the duration of roads

2. Prevent road surface from collapse, crack and being dirty

3. Be convenient for construction, time saving and cut down the cost of maintenance

4. Prevent tunnel from crack occurring

5. Further solidity slopes to proof water and soil from losses

6. Reduce the surface thickness of the ground

7. Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence

8. Be used for artificial top net of mines instead of metal ones.

Packaging & Delivery

| Packaging Details: | Rolls |

| Delivery Detail: | 20 Days |

Detiled Data

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

F&Q

1 How about the delivery time? Lead time since receipt of 30% T/T deposit payment: 3 weeks.2 What kind of payments does jenor support? T/T 3

What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4

How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5

Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6

Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: Classification and characteristics of geogrids

- Two, steel plastic composite geogrid:1 high strength steel wire, steel plastic composite geogrid tension by warp knitting bear, resulting in high tensile modulus at low strain capacity, vertical and horizontal rib synergistic effect, give full play to the role of Geogrid on soil type.2, steel plastic composite geogrid vertical steel rib weft woven into nets, an outer coating layer forming a steel wire and the outer coating layer can destroy the function of coordination, elongation is very low (less than 3%). The main force unit of steel plastic composite geogrid is steel wire, and the creep is very low.3, through the production process of plastic surface treatment, suppress the rough pattern, in order to enhance the surface roughness of the grid, improve the steel plastic composite geogrid and soil friction coefficient.4, steel plastic composite geogrid width of up to 6m, to achieve high efficiency, economic effect of reinforcement.5, steel plastic composite geogrid used high-density polyethylene can ensure that: at room temperature will not be affected by acid and alkali and salt solution, or oil erosion; will not be dissolved by water or microbial damage. At the same time, the high molecular weight of polyethylene is also sufficient to resist ultraviolet radiation caused by aging. The grille stress aspect rib synergistic effect, can not generate node crack or damage. But in the actual project, after the packing compaction, therefore has not been affected by ultraviolet light and oxygen.

- Q: How do geogrids help in reducing soil compaction?

- Geogrids help in reducing soil compaction by providing reinforcement and stabilization to the soil. They distribute the applied load more evenly, preventing concentrated pressure points that can lead to compaction. This allows for better load-bearing capacity, improved soil structure, and increased permeability, ultimately reducing the likelihood of soil compaction.

- Q: How much is the tensile strength of Geogrid

- Solder paste type: 200KN or less.

- Q: How do geogrids reduce the amount of fill required for construction?

- Geogrids reduce the amount of fill required for construction by providing reinforcement and stability to the soil, allowing for a steeper slope or thinner layer of fill to be used. This is achieved through the interlocking design of the geogrid, which distributes the load more evenly, minimizing settlement and preventing soil movement.

- Q: Are geogrids resistant to chemical attack from soil contaminants?

- Yes, geogrids are generally resistant to chemical attack from soil contaminants. Due to their high tensile strength and chemical stability, geogrids can withstand exposure to various soil contaminants without significant deterioration. However, the specific resistance may vary depending on the type of geogrid material and the nature of the soil contaminants.

- Q: How do geogrids improve the performance of mechanically stabilized slopes during seismic events?

- Geogrids improve the performance of mechanically stabilized slopes during seismic events by providing additional reinforcement and enhancing the stability of the slopes. They act as a tension element, distributing and transferring the seismic forces throughout the slope, thereby reducing the potential for slope failure and displacement. Geogrids also increase the strength and stiffness of the soil, improving its resistance to shear and lateral movement caused by seismic shaking. Overall, geogrids enhance the structural integrity of mechanically stabilized slopes, making them more resistant to seismic events.

- Q: How do geogrids improve the performance of geocomposites?

- Geogrids improve the performance of geocomposites by providing reinforcement and stabilization. They enhance the load-bearing capacity and tensile strength of the geocomposite, helping to prevent soil erosion and improve overall stability. Geogrids also increase the longevity and durability of the geocomposite, making it more resistant to deformation and damage.

- Q: Can geogrids be used in reinforced earth bridge abutments in liquefaction-prone areas?

- Yes, geogrids can be used in reinforced earth bridge abutments in liquefaction-prone areas. Geogrids are often used in such areas to provide additional stability and to mitigate the effects of liquefaction. They help distribute loads and reinforce the soil, reducing the risk of settlement or failure during liquefaction events.

- Q: Glass fiber grille modified asphalt, polyester grille coated PVC.

- It has 18 kinds of grid equipment production line, the main production and operation of all kinds of glass fiber geogrid, warp knitted polyester geogrid, unidirectional tensile plastic geogrid, two-way stretch plastic coal mine supporting soil to help network, with two-way welding plastic top net plastic composite geogrid, coal mine under biaxial tensile plastic,

- Q: How much is the geogrid 100KN

- Polyester grille price: 8 yuan

Send your message to us

Tenax Tt Uniaxial Unbiaxial Triaxial Plastic Geogrid with Bitumen Coated Black

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords