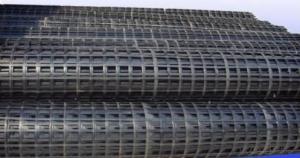

CE Certified T1000 Polypropylene Biaxial Geogrid Geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Each roll per 3 plastic belts. Other packages can be done as per request. |

| Delivery Detail: | For 40HC,within 10 days after receipt of L/C or down payment |

Specifications

Biaxial Geogrid

1.CE,ISO

2.Biaxial Geogrid Strength:15-45kn/m

3.Biaxial Geogrid Width:3.9m,3.95m,4m

4.Geogrid Length:30m,50m

Biaxial geogrid can be used to enhancement of permanent bearable toft including roads and

railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and

their main usage are as follows:

1.Enhance the bearing capacity of road foundation and extend the duration of roads.

2.Prevent road surface from collapse, crack and being dirty.

3.Be convenient for construction, timesaving and cut down the cost of maintenance.

4.Prevent tunnel from crack occurring.

5.Further solidity slopes to proof water and soil from losses.

6.Reduce the surface thickness of the ground.

7.Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence.

8.Be used for artificial top net of mines instead of metal ones.It is of fire-retardant and anti-statics.

[Specifications And Characteristics]

Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | |||||

Unit | MD | CD | MD | CD | MD | CD | MD | CD | |

True initial Modulus in Use | KN/m | 15 | 15 | 20 | 20 | 30 | 30 | 40 | 40 |

True Tensile Strength @2% Strain | KN/m | 5 | 5 | 7 | 7 | 11 | 11 | 16 | 16 |

True Tensile Strength @5% Strain | KN/m | 7 | 7 | 14 | 14 | 21 | 21 | 32 | 32 |

Junction Efficiency | % | 100 | 100 | 100 | 100 | ||||

Flexural Stiffness | mg-cm | 280.000 | 780,000 | 900,000 | 1,200,000 | ||||

Aperture Stability | kg-cm/deg | 3.1 | 4.8 | 4.3 | 3.4 | ||||

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | ||||

Resistance to Long Term Degradation | % | 100 | 100 | 100 | 100 | ||||

Unit Weight | g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | ||||

Rolls Dimensions (Length, Width) | m | 50×3.95 | 50×3.95 50X5 | 50×3.95 | 50×3.95 | ||||

Lading Capacity | Rolls/40HC | 300 | 260 | 140 | 100 | ||||

- Q: What kind of geotextiles are used in highway geotextiles?

- Highway geotextile general use Hongxiang new material filament geotextile, to overcome the cracks and so on the road defects.

- Q: are they used for same purpose with just different terminology?

- Geotextiles And Geomembranes

- Q: Geotextile universal testing machine with 20kn enough?

- Enough, we use is 20kn

- Q: How do geotextiles reduce construction time and cost?

- Geotextiles reduce construction time and cost by providing several benefits. Firstly, they act as a separation layer, preventing the mixing of different types of soil, which eliminates the need for additional excavation and replacement. Secondly, they enhance the stability and strength of the soil, allowing for the use of less expensive and readily available materials in construction. Moreover, geotextiles minimize erosion and sedimentation, reducing the need for costly erosion control measures. Additionally, they can expedite the construction process by providing immediate load-bearing capacity, eliminating the need for time-consuming soil consolidation. Overall, geotextiles offer cost-effective solutions that save time, materials, and resources during construction.

- Q: How are geotextiles used in geotechnical engineering?

- Geotextiles are commonly used in geotechnical engineering to provide reinforcement, filtration, separation, and drainage in various construction projects. These permeable fabrics are placed within soil or rock structures to enhance their performance, prevent soil erosion, improve stability, and control water flow. Geotextiles are especially useful in road construction, embankments, retaining walls, landfills, and coastal engineering, as they offer cost-effective solutions and contribute to the sustainability and longevity of these structures.

- Q: How do geotextiles help with soil separation in subgrade improvement projects?

- Geotextiles are used in subgrade improvement projects to separate different soil layers, preventing them from mixing. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This helps to maintain the stability and strength of the subgrade, reducing the risk of settlement and soil erosion.

- Q: How do geotextiles help in subsurface drainage?

- Geotextiles help in subsurface drainage by acting as a filter and separation layer between the soil and the drainage material. They prevent the soil particles from clogging the drainage system while allowing water to pass through, promoting efficient water flow and preventing waterlogging.

- Q: How to determine the nominal breaking strength of filament spunbonded nonwoven geotextile

- You can use a dedicated geotextile strong test machine detected.

- Q: Can geotextiles be used for reinforcement of underground tunnels?

- Yes, geotextiles can be used for reinforcement of underground tunnels. Geotextiles are commonly used in civil engineering projects, including tunnel construction, to provide reinforcement, drainage, and separation. In the case of underground tunnels, geotextiles can be installed to prevent soil erosion, provide stability, and enhance the overall structural integrity of the tunnel.

- Q: Waterproof geotextile in which the location of the culvert, what use

- Used in the top and side, lining the inside, mainly the role of waterproof to prevent water seepage. Huazhi geotechnical materials manufacturers need to answer for your needs

Send your message to us

CE Certified T1000 Polypropylene Biaxial Geogrid Geotextile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords