Gmb Geogrid

Gmb Geogrid Related Searches

Geogrid Machine Geostar Geogrid Geogrid Membrane Geogrid Layer Geogrid Australia Geogrid Energy Geogrid Tbl Geogrid Com Geogrid Road Geogrid Grass Geogrid Maps Geogrid Market Grass Geogrid Geogrid Mat Gravel Geogrid Geogrid Slope Geogrid Paving Geogrid Gravel Geogrid Philippines Geogrid Parking Geogrid Paver Universal Geogrid Geogrid Pavement Keystone Geogrid Miragrid Geogrid Geogrid China Geogrid Fence Geogrid Road Base Geogrid Textile Geogrid AnchorsGmb Geogrid Supplier & Manufacturer from China

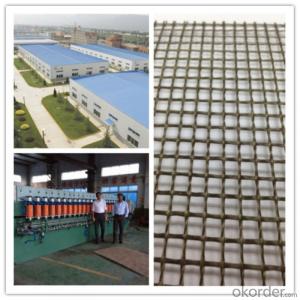

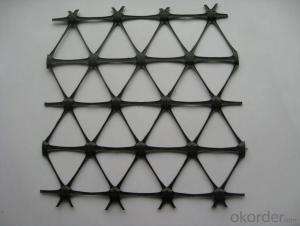

GMB Geogrid is a range of high-quality geosynthetic products designed for various civil engineering and construction applications. These products are engineered to enhance the performance of soil structures, provide stability, and improve the overall efficiency of projects. Gmb Geogrid is widely used in applications such as road construction, slope protection, soil reinforcement, and erosion control, making it an essential component in the construction industry.Gmb Geogrid products are utilized in a variety of scenarios to improve the structural integrity and performance of soil and other materials. They are particularly effective in applications where increased load-bearing capacity and reduced settlement are required. The geogrids are designed to interlock with the soil particles, creating a strong and stable structure that can withstand heavy loads and resist deformation. This makes them ideal for use in projects such as roadbeds, retaining walls, and landfill liners, where soil stability and strength are critical factors.

Okorder.com is a leading wholesale supplier of Gmb Geogrid products, offering a vast inventory to meet the needs of various construction projects. As a reputable supplier, Okorder.com ensures that the Gmb Geogrid products they provide are of the highest quality and meet industry standards. This makes them a reliable source for contractors and engineers seeking to incorporate these geosynthetic materials into their projects. With a large inventory and competitive pricing, Okorder.com is the go-to destination for Gmb Geogrid products.

Hot Products