Plastic Biaxial Geogrid with CE Certificate for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 85800 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

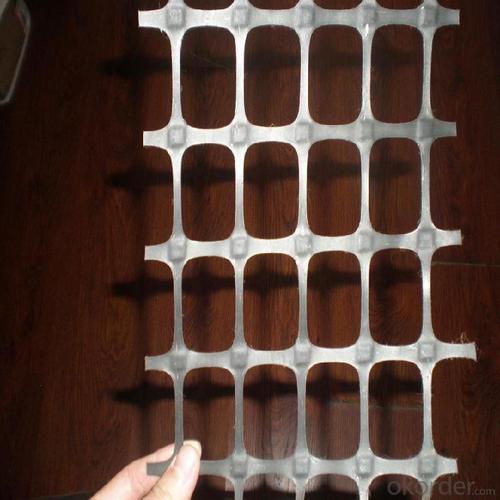

The Description of Plastic Biaxial Geogrid

Plastic Biaxial Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

The details of Plastic Biaxial Geogrid

| Type: | Geogrid | Material: | Biaxial Geogrid | Place of Origin: | China (Mainland) |

| Certificates: | CE,ISO | Color : | White & Black | Width : | 1m--6m |

| Length | 50-200m | Mesh Size: | 10-40mm | Tensile Strength | 30KN-300KN |

| Area Weight | 130-900g/sm | Package | PP bags or PE film | Approximate mesh size | 12.7*12.7 25*25 40*40 |

Packaging & Delivery

| Packaging Details | PP bags or PE film. Or Packed as customers' requests; |

| Delivery Detail | 10-20days after see the payment. |

Remarks: we are very large fortune 500 enterprise with more than 20branches in worldwide, and have almost ten years export experience in geosynthetic field. We have kunlun bank account and have many Iran geosynthetics customers.So if any question or support, please just feel free to contact me at any time.

- Q: How do geogrids improve the performance of geocell-reinforced slopes?

- Geogrids improve the performance of geocell-reinforced slopes by providing additional strength and stability to the structure. They help distribute the load more evenly across the geocell system, preventing soil erosion and reducing the risk of slope failure. Geogrids also increase the overall tensile strength of the geocell-reinforced slope, making it more resistant to external forces such as water flow or seismic activity.

- Q: Are geogrids suitable for use in slope stabilization for mining haul roads?

- Yes, geogrids are suitable for use in slope stabilization for mining haul roads. Geogrids are engineered materials that provide reinforcement and stability to slopes by increasing soil strength and preventing erosion. They are commonly used in road construction, including mining haul roads, to improve their load-bearing capacity and resistance to slope failures. Geogrids are effective in preventing soil movement and controlling erosion, making them a reliable choice for slope stabilization in mining haul road applications.

- Q: How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first preparing the ground surface and ensuring it is compacted and leveled. The geogrid is then laid out on the prepared surface and secured in place using stakes or anchor systems. It is important to ensure that the geogrid is properly tensioned and aligned to provide maximum stability and reinforcement. Finally, the geogrid is covered with additional layers of soil or other construction materials to complete the installation.

- Q: What is the cost of geogrid installation?

- The cost of geogrid installation can vary depending on various factors such as the size of the project, the type and quality of geogrid being used, location, and labor costs. It is best to consult with a professional contractor or supplier to get an accurate estimate for your specific installation needs.

- Q: Can geogrids be used in reinforcement of gabion structures?

- Yes, geogrids can be used in the reinforcement of gabion structures. Geogrids are commonly used to increase the stability and strength of gabion walls by providing additional support and preventing soil erosion. They are typically placed within the gabion structure to enhance its load-bearing capacity and overall performance.

- Q: Are geogrids suitable for coastal engineering projects?

- Yes, geogrids are suitable for coastal engineering projects. They provide effective erosion control, stabilize slopes, and reinforce soil structures in coastal areas. Geogrids help to prevent soil erosion caused by waves, tides, and storm surges, making them an ideal solution for coastal protection and resilience.

- Q: Can geogrids be used in ground reinforcement for sports fields?

- Yes, geogrids can be used in ground reinforcement for sports fields. Geogrids provide stability, improve load-bearing capacity, and prevent soil erosion, making them a suitable choice for reinforcing the ground in sports fields and ensuring a durable playing surface.

- Q: Specifications and parameters of Geotextiles

- Product specification is between SNG100-SNG1500. Width is 1-8m, long 50-100m (or according to customer requirements to produce)

- Q: How do geogrids improve the load distribution in pavements?

- Geogrids improve the load distribution in pavements by providing reinforcement and increasing the stability of the structure. They distribute the load more evenly across the pavement, reducing stress on the layers beneath. This helps to prevent cracking, rutting, and other forms of pavement distress, ultimately extending the lifespan of the pavement.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials made from polymers, typically high-density polyethylene (HDPE) or polyester, that possess a unique set of properties and characteristics. These include high tensile strength, low elongation, and excellent resistance to chemical degradation and biological attack. Geogrids also have a high modulus of elasticity, which allows them to distribute stress and improve the load-bearing capacity of soils and aggregates. They are typically lightweight and easy to handle, making them convenient for construction applications. Geogrids exhibit excellent dimensional stability and resistance to creep, ensuring their long-term effectiveness. They are also resistant to UV degradation and have a long design life. Overall, geogrids are versatile materials that provide reinforcement, stabilization, and confinement in various civil engineering projects, such as road construction, slope stabilization, and erosion control.

Send your message to us

Plastic Biaxial Geogrid with CE Certificate for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 85800 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords