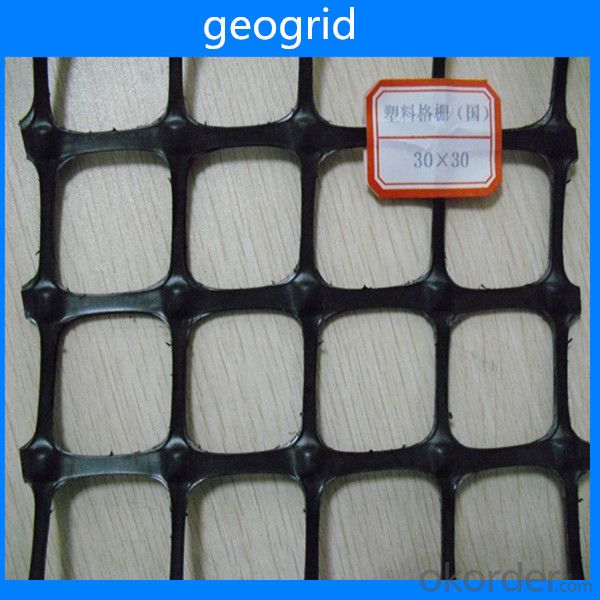

Tenax Biaxial Plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 360000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item:

Polypropylene Biaxial geogrid

1.Material:Polypropylene

2.Tensile strength :15-15KN/M

3.Elongation @Longitudinal Elongation:15%

4.Elongation@Transverse Elongation:13%

Biaxial gegrid is manufactured from polypropylene,mainly applied in strengthening soft ground of highway ,railway,slope protecting projects,airfields etc.It can increase stability and loading of funds,prolong the project life.

Features:

1.With high tensle strength in longitudinal and transverse directions

2.Provide an chain system of more effective force bearing and spreading for the soil.

Function:

Biaxial geogrid is applicable to the reinforcement of permanent load-carrying foundations of large areas.

- Q: What materials are geogrids made of?

- Geogrids are typically made of high-strength polymers, such as polyester or polyethylene, which are woven or knitted to create a grid-like structure.

- Q: What kind of circumstances need to shop geogrid

- The mechanism of geogrid reinforced soil exists in the interaction between Geogrid and soil. Generally, it can be concluded that the friction between Geogrid and soil, the locking effect of Geogrid on Soil and the passive resistance of grid ribs. The three kinds of actions can restrain the lateral displacement of the soil, which greatly increases the stability of the soil, and the reinforcement effect of the soil is obviously higher than that of other geotextile.

- Q: How do geogrids improve the performance of geosynthetic-reinforced embankments?

- Geogrids improve the performance of geosynthetic-reinforced embankments by providing tensile strength and reinforcing the soil, thereby increasing stability and load-bearing capacity. They distribute lateral forces and reduce settlement, preventing slope failure and soil erosion. Additionally, geogrids enhance the overall durability and longevity of the embankment structure.

- Q: Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q: Are geogrids cost-effective?

- Yes, geogrids can be considered cost-effective. Geogrids help to improve the stability and performance of soil structures, reducing the need for excessive amounts of expensive construction materials. They also have a longer lifespan compared to traditional methods, resulting in lower maintenance and replacement costs over time. Additionally, geogrids can enhance project efficiency by reducing construction time and labor costs.

- Q: Are geogrids resistant to hydrolysis?

- Yes, geogrids are generally resistant to hydrolysis.

- Q: Are geogrids suitable for use in reinforced steep slopes?

- Yes, geogrids are suitable for use in reinforced steep slopes. Geogrids provide additional strength and stability to the soil, preventing erosion and maintaining the integrity of the slope. They are designed to withstand high tensile forces, making them ideal for reinforcing steep slopes and preventing soil movement.

- Q: Can geogrids be used in reinforcement of underground pipelines?

- Yes, geogrids can be used in the reinforcement of underground pipelines. Geogrids are often used to provide additional strength and stability to the surrounding soil, which can help prevent pipeline movement or damage due to settlement or external loads. By distributing the load more evenly and reducing stress on the pipeline, geogrids can enhance the overall performance and longevity of underground pipeline systems.

- Q: How do geogrids improve the performance of reinforced soil walls?

- Geogrids improve the performance of reinforced soil walls by providing additional strength and stability to the soil structure. They act as a reinforcement material, distributing the forces exerted on the wall more evenly and preventing the soil from sliding or collapsing. This results in increased load-bearing capacity, reduced settlement, and improved overall stability of the reinforced soil walls.

- Q: Can geogrids be used in reinforcement of concrete pavements?

- Yes, geogrids can be used in the reinforcement of concrete pavements. Geogrids are commonly used to enhance the structural integrity and performance of concrete pavements by providing additional tensile strength and distributing loads more effectively. They can help prevent cracking and increase the overall durability of the pavement.

Send your message to us

Tenax Biaxial Plastic Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 360000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords