High Quality PP Biaxial Geogrid 30KN/30KN for Civil Engineering Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

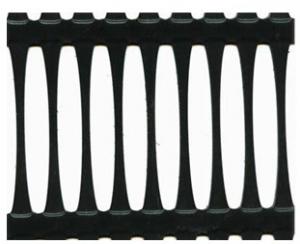

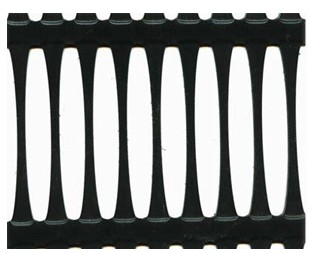

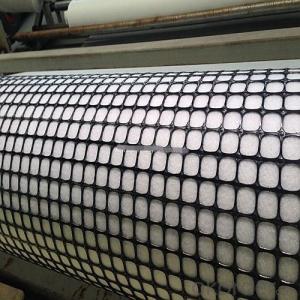

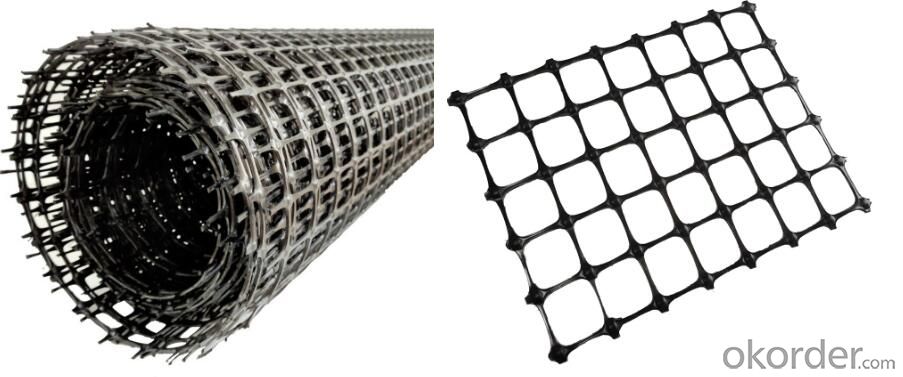

Introduction of Shandong High Quality PP Biaxial Geogrid 30KN/30KN:

PP Biaxial geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching, heating,

longitudinal stretching and transverse stretching.

Performance of High Quality PP Biaxial Geogrid 30KN/30KN:

---Homogeneous structure, low creep, anti-aging and resisting acid & alkaline.

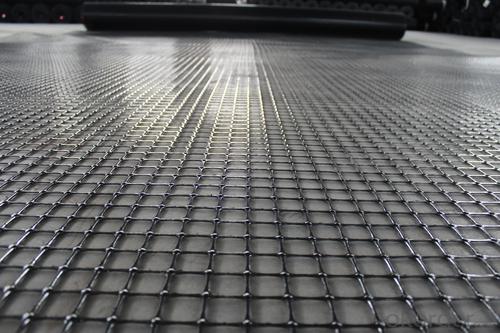

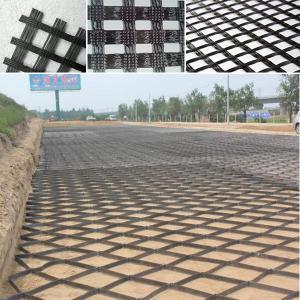

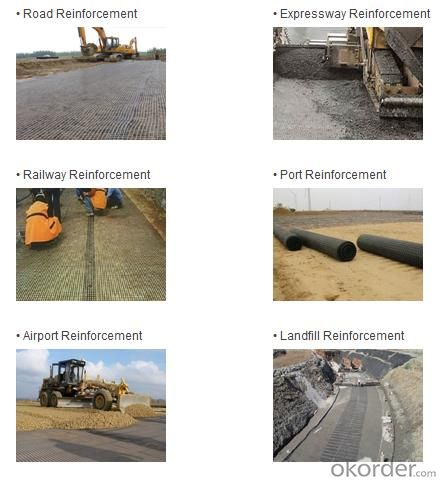

Applications of High Quality PP Biaxial Geogrid 30KN/30KN:

--Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement,

not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

--Used in highway, railway, port, airport and municipal project.

--Support in the recovery working face of coal mine and roadway in the coal mine.

Specifications of High Quality PP Biaxial Geogrid 30KN/30KN:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

- Q: How do geogrids improve the performance of unpaved trails?

- Geogrids improve the performance of unpaved trails by providing reinforcement and stabilization to the soil. They distribute the load more evenly, preventing the soil from shifting and becoming uneven. This helps to reduce erosion, increase the load-bearing capacity, and enhance the overall durability and longevity of the trail.

- Q: Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Different specifications and models can not compare the price, generally speaking, the same specifications, more expensive than glass fiber

- Q: Can geogrids be used in underground mining operations?

- Yes, geogrids can be used in underground mining operations. Geogrids are commonly employed in underground mining to provide reinforcement and stabilization to the surrounding rock and soil. They can help prevent slope failures, control ground movement, and enhance the overall safety and efficiency of mining operations.

- Q: What is the difference between geotextiles and geogrids?

- The geotextile is mainly used for seepage control, isolation, geogrid are generally used in reinforcement reinforcement, the two are essentially different, in the use of the process is sometimes used in the same project, for example, high-speed railway project is made of polypropylene production grid and polyvinyl chloride polymer and thermoplastic or die of two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid

- Q: Performance parameters of steel plastic geogrid

- The ultimate tensile strength of KN/m type per meter per meter of elongation 100 times per meter KN/m% freeze thawing ultimate tensile strength

- Q: How to restore the plastic geogrid after being destroyed?

- 3 when laying geosynthetics, the direction of high strength should be placed in the main stress direction of the embankment.4 geosynthetic materials should be paved after the design requirements of the back section, and timely coverage with sand.

- Q: How do geogrids reduce settlement in embankments?

- Geogrids reduce settlement in embankments by providing reinforcement and improving stability. They distribute loads more evenly across the soil, preventing excessive consolidation and settlement. Moreover, the geogrids also enhance the bearing capacity of the embankment, preventing soil failure and reducing settlement further.

- Q: Can geogrids be used in temporary construction access mats for environmentally sensitive areas?

- Yes, geogrids can be used in temporary construction access mats for environmentally sensitive areas. Geogrids are highly durable and can provide stabilization and support to heavy construction equipment while minimizing environmental impacts. They distribute the load more evenly, reducing soil compaction and preventing damage to the sensitive ecosystem. Additionally, geogrids can be easily removed after the construction is complete, leaving minimal disturbance to the area.

- Q: How do geogrids improve the stability of shorelines?

- Geogrids improve the stability of shorelines by providing reinforcement and preventing soil erosion. They are typically placed beneath the soil surface, acting as a stabilizing layer that distributes the applied loads and helps prevent the soil from sliding or slumping. Geogrids also enhance the cohesion between soil particles, increasing the overall stability of the shoreline and resisting the forces of waves, currents, and tides.

- Q: Geotextiles and geogrids to do the re inspection approach?

- In theory it is necessary

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality PP Biaxial Geogrid 30KN/30KN for Civil Engineering Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords