Biaxial PVC Coated Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

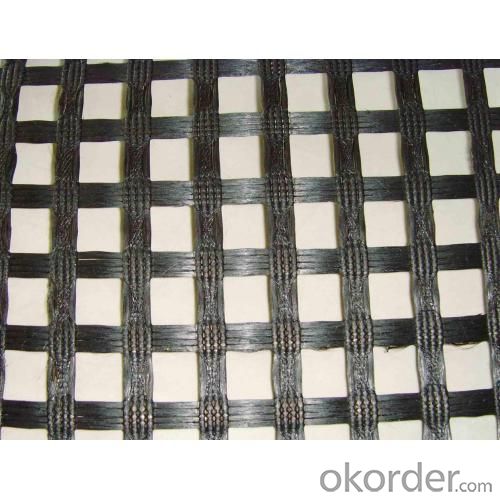

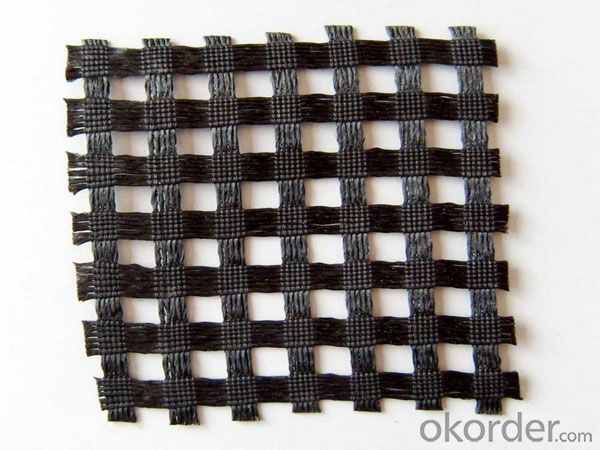

Structure of PVC Coated Geogrid Description:

PVC Coated Geogrid defined as a grid structure of polymeric material formed by weaving or knitting intersecting ribs with appropriate apertures (opening sizes) to allow interlocking with surrounding soil, rock, earth and other surrounding materials. There are two basic categories of geogrids. Uniaxial geogrids designed to endure stress in one direction. Their main strength is in the machine direction making these grids suitable for wall and slope applications.

Main Features of PVC Coated Geogrid

Improving bearing capacity of retaining wall or dam

Extending the project life

Reducing floor area

Shortening construction period, reducing cost and maintaining expense

PVC Coated Geogrid Images

PVC Coated Geogrid Specification:

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 | |

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They distribute the applied loads more evenly, reduce soil movement and prevent the occurrence of sliding or failure. Additionally, geogrids increase the bearing capacity of the soil, enhance drainage, and improve overall durability and longevity of the retaining structures.

- Q: How do geogrids enhance the performance of reinforced embankments?

- Geogrids enhance the performance of reinforced embankments by providing a stable and strong reinforcement layer. They distribute and transfer loads more efficiently, reducing lateral spreading and settlement. Geogrids also increase the overall stability of the embankment, preventing erosion and maintaining its integrity over time.

- Q: Who knows the laying method of geogrid?

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: What are the testing methods for geogrids?

- The testing methods for geogrids typically involve evaluating their tensile strength, aperture size, junction strength, and creep characteristics through laboratory tests such as wide-width tensile strength test, puncture test, junction efficiency test, and long-term creep test. These methods help determine the geogrids' performance and suitability for various soil stabilization and reinforcement applications.

- Q: How do geogrids help stabilize soil?

- Geogrids help stabilize soil by providing reinforcement and increasing the overall strength of the soil. They are typically made of high-strength materials such as polyester or polypropylene, and are placed within the soil to distribute loads and limit movement. This prevents soil erosion, improves slope stability, and enhances the bearing capacity of the soil, thus effectively stabilizing it.

- Q: What are the long-term maintenance requirements for geogrids?

- The long-term maintenance requirements for geogrids are typically minimal. Once installed properly, geogrids generally do not require any specific maintenance. However, regular inspections are recommended to ensure that the geogrids are functioning as intended and to identify any potential damage or deterioration. In case any issues are detected, prompt repairs or replacements should be carried out to maintain the effectiveness of the geogrids over time.

- Q: What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to ensure proper preparation of the subgrade, followed by unrolling the geogrid on top and securing it with stakes or pins. It is important to overlap the geogrid panels correctly and avoid any wrinkles or folds. Finally, cover the geogrid with the desired fill material and compact it properly to maximize the effectiveness of the geogrid.

- Q: The future of geotechnical materials

- steel-plastic composite geogridThe steel plastic geogrid with the high strength steel wire, through the special treatment, and PE, and the addition of other additives, through extrusion to make it into a composite high tensile band, and the surface of the coarse grain, it is high strength reinforced geotextile. The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint.

- Q: How do geogrids help in reducing the need for excavation and grading?

- Geogrids help in reducing the need for excavation and grading by providing structural support and reinforcement to the soil. They distribute the load more evenly, preventing soil movement and settling. This reduces the need for extensive excavation and grading, as the geogrids help stabilize the soil, allowing for the construction of roads, slopes, and retaining walls with minimal earthwork.

- Q: How does a geogrid work?

- A geogrid works by providing reinforcement to soil or other materials. It is typically made of high-strength polymers or fibers arranged in a grid-like pattern. When placed within the soil, the geogrid interlocks with the surrounding particles, creating a stable network. This enhances the tensile strength and overall performance of the soil, preventing excessive movement, erosion, or failure. The geogrid redistributes applied loads, reducing stress concentrations and improving the stability and longevity of structures like retaining walls, roadways, and embankments.

Send your message to us

Biaxial PVC Coated Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords