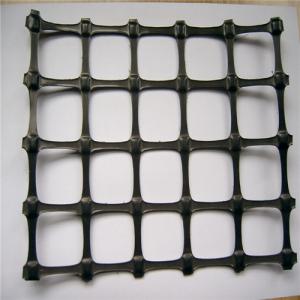

PP Biaxial/Unixial Geogrid Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP geogrid Description

PP geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching, heating, longitudinal stretching and transverse stretching.

PP geogrid Specification

Tensile Strength: 15KN-15KN, 40KN-40KN, 50KN-50KN, etc

Roll Size: 3.95x100m, 2x50m, as request.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

PP geogrid Property

1) Not easy to produce static after friction.

2) Good flame retardant performance.

3) Strong anti-corrosion and rust resistance.

4) High bearing capacity, low elongation.

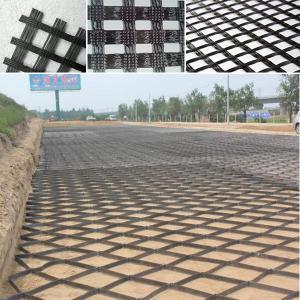

PP geogrid Application

1) Coal mine channel.

2) Slope protection in tunnel and expressway.

3) Anti-seismic reinforcement of buildings.

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q: Are geogrids resistant to seismic forces?

- Yes, geogrids are designed to be resistant to seismic forces. They are made from durable materials that can withstand the dynamic forces generated during an earthquake, providing stability and reinforcement to soil and structures. Geogrids help distribute seismic forces and prevent soil liquefaction, making them a reliable solution in areas prone to earthquakes.

- Q: How do geogrids improve the stability of channel linings?

- Geogrids improve the stability of channel linings by providing reinforcement and preventing soil erosion. They enhance the tensile strength of the soil, reducing the risk of slope failure and increasing the overall stability of the channel lining.

- Q: What are the benefits of using geogrids in pavement construction?

- There are several benefits of using geogrids in pavement construction. Firstly, geogrids enhance the pavement's structural integrity by providing additional tensile strength. This helps to distribute loads more evenly, reducing the risk of cracking or rutting. Secondly, geogrids improve the pavement's durability and lifespan by resisting the effects of fatigue and aging. They can also help to reduce maintenance costs over time. Additionally, geogrids aid in preventing reflective cracking, which occurs when cracks from the underlying pavement transfer to the surface. By reinforcing the pavement layers, geogrids minimize the likelihood of reflective cracking, resulting in a smoother and safer road surface.

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- Geomembrane, composite geomembrane, geotextile, geogrid, geotextile, geotextile bags, etc. are called geosynthetics. The coefficient of permeability is a kind of soil properties;

- Q: Can geogrids be used in reinforcement of tunnels and underground excavations?

- Yes, geogrids can be used in the reinforcement of tunnels and underground excavations. Geogrids are commonly utilized in such applications to enhance soil stabilization, reduce soil movement, and provide structural support. They can effectively distribute the load and improve the overall stability and longevity of tunnels and underground excavations.

- Q: What is the single geogrid 60kN/m

- Unidirectional geogrid, the tensile strength is not less than 60 kn per meter

- Q: Can geogrids be used in pipeline trench stabilization applications?

- Yes, geogrids can be used in pipeline trench stabilization applications. Geogrids are commonly used in civil engineering and construction projects to reinforce soil and provide stability. They can be used in pipeline trench stabilization to prevent soil erosion, improve load distribution, and enhance the overall strength and performance of the pipeline system.

- Q: Are geogrids suitable for erosion control?

- Yes, geogrids are suitable for erosion control. Geogrids provide reinforcement and stabilization to soil, preventing erosion by reinforcing the ground and reducing the movement of soil particles. They are effective in controlling erosion in areas with steep slopes or high water flow, making them a suitable solution for erosion control projects.

- Q: What is the meaning of 400g geotextiles /100g woven fabric

- Main production, geotextile, geogrid, geomembrane

- Q: What is the quota of two-way steel plastic composite geogrid

- The algorithm is similar to that of the bottom of the plate, not by the area of the grid, but by calculating the length of the theoretical weight.

Send your message to us

PP Biaxial/Unixial Geogrid Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords