Red Aluminum Trim Coil

Red Aluminum Trim Coil Related Searches

Trim Coil Aluminum Colored Aluminum Trim Coil Black Aluminum Trim Coil Green Aluminum Trim Coil White Aluminum Trim Coil Vinyl Coated Aluminum Trim Coil Alcoa Aluminum Trim Coil Rollex Aluminum Trim Coil Aluminum Siding Trim Coil Almond Aluminum Trim Coil Textured Aluminum Trim Coil Aluminum Trim Coil Roll Bending Aluminum Trim Coil Poly Aluminum Trim Coil Gray Aluminum Trim Coil Mastic Aluminum Trim Coil Alside Aluminum Trim Coil Painted Aluminum Trim Coil Installing Aluminum Trim Coil Aluminum Vinyl Siding Trim Coil Clay Aluminum Trim Coil Brown Aluminum Trim Coil Menards Aluminum Trim Coil Best Aluminum Trim Coil Spectra Aluminum Trim Coil Pvc Aluminum Trim Coil Amerimax Aluminum Trim Coil 10 Inch Aluminum Trim Coil Painting Aluminum Trim Coil Wood Grain Aluminum Trim CoilRed Aluminum Trim Coil Supplier & Manufacturer from China

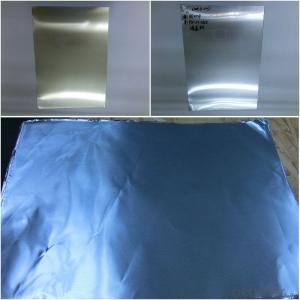

Red Aluminum Trim Coil is a versatile product that consists of long rolls of aluminum material, designed for various applications in construction, renovation, and decoration. This product is known for its durability, corrosion resistance, and aesthetic appeal, making it a popular choice for both commercial and residential projects. The red color adds a vibrant touch to any space, enhancing the overall visual appeal while providing a sturdy and long-lasting solution for trim and edging needs.Red Aluminum Trim Coil is widely used in various settings, including offices, homes, retail spaces, and public buildings. It is commonly applied to window and door frames, wall corners, and ceiling edges to provide a clean, finished look. Additionally, it can be used for creating decorative accents, such as moldings and trims, adding a touch of elegance to any interior or exterior design. The product's flexibility allows it to be easily cut and shaped to fit various dimensions and styles, making it a convenient and cost-effective option for a multitude of projects.

Okorder.com is a leading wholesale supplier of Red Aluminum Trim Coil, boasting a large inventory that caters to the diverse needs of contractors, builders, and DIY enthusiasts. By offering this product at competitive prices and with a commitment to quality, Okorder.com ensures that customers receive the best value for their investment. With a wide range of sizes and thicknesses available, Red Aluminum Trim Coil from Okorder.com is the go-to choice for professionals and homeowners alike who demand the highest standards in materials and service.

Hot Products