Rustic Red Aluminum Coil for Cookware Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of DC Aluminium in Coil Form for making Aluminium Circle Description

DC Aluminium in Coil Form for making Aluminium Circle is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Feature of DC Aluminium in Coil Form for making Aluminium Circle

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

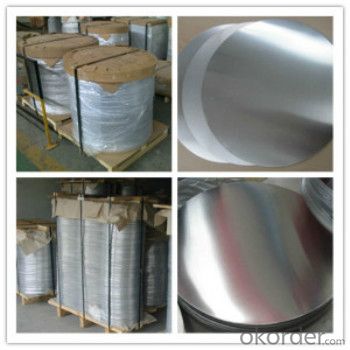

3. Image of DC Aluminium in Coil Form for making Aluminium Circle

4. Specification of DC Aluminium in Coil Form for making Aluminium Circle

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

5. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What about payment term?

30% T/T in advance, balance against B/L COPY or 100% L/C AT SIGHT.

- Q: I am wondering if a deodorant made with aluminum silicate is safer than one with aluminum salt.

- aluminum silicates have been used in deodorants for years. there was a time when it was thought that the Al in the deodorants was causing alzheimers but that has been shown to be wrong. if there are other dangers to the silicates, we haven't found them or they aren't that bad

- Q: How to deal with too much aluminum powder in aluminum striping?

- Currently, there are bag dust-removal system and water dust-removal system. The former is very popular with enterprises because of low maintenance cost, accounting for over 90%. But the problem is the dust accumulation because the ventilation and dust removal systems are not produced in strict accordance with the standard. For example, controlling wind speed does not meet the requirement; ventilation and dust removal system does not meet the requirements of explosion-proof, including the set of pipes, series and parallel connection, the choice of dust removal system, the spark detection and extinguishing measures.

- Q: What is the tensile strength of aluminum coils?

- The tensile strength of aluminum coils can vary depending on the specific alloy and temper used. However, on average, aluminum coils have a tensile strength ranging from 150 to 300 megapascals (MPa). This means that aluminum coils can withstand a pulling force of 150 to 300 MPa before breaking or deforming. It is important to note that the tensile strength may be influenced by factors such as the thickness of the coil, the manufacturing process, and any additional treatments or coatings applied to the aluminum.

- Q: What specific tools are required for handling and working with aluminum coils?

- <p>Working with aluminum coils typically requires specialized tools to ensure safety and efficiency. These include cutting tools like metal snips or shears designed for aluminum, which are crucial for cutting the coils without damaging them. Additionally, a coil carrier or uncoiler is necessary for handling and unrolling the coils without causing injury or deformation. Protective gear such as gloves and safety glasses is also essential to prevent injuries from sharp edges or debris. For more precise work, a metal straightener or leveling machine may be needed to correct any warping in the aluminum coils.</p>

- Q: Can aluminum coils be used in high-magnetic field applications?

- No, aluminum coils are not suitable for high-magnetic field applications since aluminum is not magnetic and cannot effectively interact with magnetic fields.

- Q: The company wants to produce an aluminum coil production line, which is better for large aluminium smelting equipment?

- Dongpu heat well, they have the qualification certificate issued by the state kiln construction, as far as I know, their melting furnace Aluminum Alloy 'plan is very good, and the operation is simple and safe, feel good, can be wiped off

- Q: How to calculate the length of aluminum sheet with the thickness known?

- Thickness*width*length=weight/density, length=weight/(density*thickness*width). Ps: Keep unit the same.

- Q: Are aluminum coils suitable for insulation applications?

- Indeed, insulation applications find aluminum coils to be a fitting option. The outstanding thermal conductivity properties of aluminum make it a widely preferred material for insulation purposes. Its ability to effectively deflect heat and cold renders it an efficient choice for insulating applications. What's more, aluminum coils boast lightweight construction, durability, and resistance to corrosion, rendering them suitable for a range of insulation requirements. Their installation is hassle-free, and they offer enduring insulation performance. In summary, aluminum coils emerge as an exceptional selection for insulation applications.

- Q: What is the typical density of aluminum coils?

- The typical density of aluminum coils can vary depending on the specific alloy and the manufacturing process used. However, in general, the density of aluminum coils is typically around 2.7 grams per cubic centimeter (g/cm³). This value is slightly less than that of pure aluminum, which has a density of 2.7-2.8 g/cm³. It is important to note that the density of aluminum coils can also be influenced by factors such as the thickness of the coil and any additional coatings or treatments applied to the surface.

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Yes, aluminum coils can be used in the production of fire-resistant structures. Aluminum is naturally fire-resistant and has a high melting point, making it an ideal material for structures that need to withstand high temperatures. Aluminum coils are commonly used in the construction industry for fire-resistant applications such as roofs, walls, and insulation. Additionally, aluminum is lightweight and durable, making it easier to install and maintain in fire-resistant structures.

Send your message to us

Rustic Red Aluminum Coil for Cookware Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords