Aluminum Coil suppliers Wholesale in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

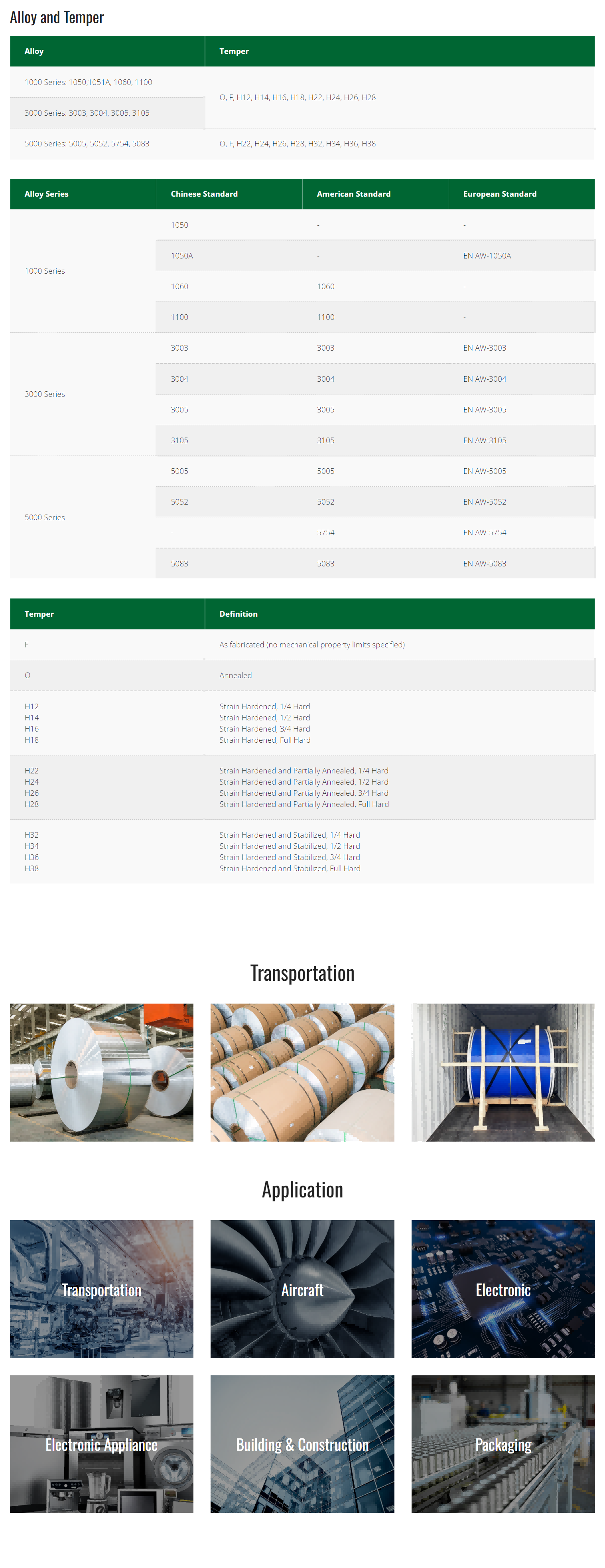

Specification

Aluminum Coil Wholesale in China is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc..Aluminum Coil Wholesale in China is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

Main Features:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

Images:

Images:

FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

2. Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

3. What is the delivery time after purchase?

35 day after receiving client's deposit or correct LC

4.What is Anodized Aluminum and How does the Anode effect impact Electrolysis?

Anodized aluminum refers to aluminum and aluminum alloy plated layer of dense alumina in order to prevent further oxidation, the chemical properties of alumina same. But with the general oxide film is different; it can be stained with anodized aluminum electrolytic coloring.

Anode effect is a phenomenon unique to molten salt electrolysis, and to the performance of aluminum production is still evident. Production of anode effect occurs when the cell voltage rises sharply, reaching 20 ~ 50V, and sometimes even higher. It occurs a significant impact on the entire series of electrolysis, a current efficiency is reduced, the impact of the various technical indicators electrolysis, and so reduces yield and quality aluminum, undermining the smooth supply whole series of electrolysis. In the method of treatment, no more than two ways: with effect rod (stick) extinguish or reduce the anode, increasing the quantity of alumina, in order to achieve the purpose of extinguishing the anode effect. It has yet to find a better approach.

- Q: How to calculate the wall thickness with the gross weight of aluminum coil known?

- Gross weight*density=volume volume÷(aluminum sheet *width)=thickness

- Q: How do aluminum coils contribute to indoor air quality?

- Aluminum coils used in heating, ventilation, and air conditioning (HVAC) systems do not directly contribute to indoor air quality. However, they play a crucial role in maintaining indoor air quality by helping to cool and dehumidify the air. By efficiently transferring heat and moisture, aluminum coils aid in controlling temperature and humidity levels, preventing the growth of mold, mildew, and other harmful microorganisms that can negatively impact indoor air quality.

- Q: What are the different coil recoiling options available for aluminum coils?

- There are several coil recoiling options available for aluminum coils, depending on the specific requirements and desired outcomes. One option is the oscillate recoiling method, which involves winding the aluminum coil in a zigzag pattern. This technique helps to reduce coil set and improve flatness, making it suitable for applications where a flat, smooth surface is crucial. Another option is the traverse winding method, which involves winding the aluminum coil back and forth in a controlled manner. This technique helps to evenly distribute the tension across the coil, reducing the risk of coil breaks and ensuring consistent performance. Additionally, there are options for coil slitting and rewinding. Slitting involves cutting the aluminum coil into narrower strips, which can be rewound into smaller coils. This option is commonly used when smaller coil sizes are required for specific applications. Furthermore, some recoiling options include coil rewinding with tension control systems. These systems ensure that the tension applied during rewinding is controlled and consistent, helping to prevent overstretching or deformation of the aluminum coil. Overall, the choice of coil recoiling options for aluminum coils depends on factors such as the desired surface finish, coil size requirements, and specific application needs. Manufacturers and processors of aluminum coils can provide guidance and expertise in selecting the most suitable recoiling option based on these considerations.

- Q: What is the balanced chemical equation for aluminum and cobalt?That is all the information that the question gives. If you could help me out, I would really, really appreciate it.

- That's pretty sparse. Perhaps the question is referring to a single replacement reaction. Aluminum is above cobalt in the activity series, which allows us to predict that aluminum metal will reduce cobalt ions, while aluminum is oxidized. This occurs as long as there is an ion present which will react with the aluminum oxide layer on the surface of aluminum. This passivating Al2O3 layer keeps aluminum metal from reacting. The presence of chloride ions will break down the passivating layer allowing the aluminum metal below to react. Al2O3(s) + 6H+ + 8Cl- -- 2[AlCl4]- + 3H2O(l) 2Al(s) + 3Co2+ -- 2Al3+ + 3Co(s)

- Q: Are aluminum coils resistant to oil and grease?

- Yes, aluminum coils are generally resistant to oil and grease.

- Q: Can aluminum coils be used in the production of transportation vehicles?

- Yes, aluminum coils can be used in the production of transportation vehicles. Aluminum is lightweight, durable, and resistant to corrosion, making it a suitable material for various transportation applications such as cars, trucks, trains, and airplanes. Using aluminum coils in vehicle manufacturing helps improve fuel efficiency, reduce emissions, and increase overall performance.

- Q: What is the reflectivity of aluminum coils?

- The reflectivity of aluminum coils refers to the ability of these coils to reflect light. Aluminum is known for its high reflectivity, with a reflectivity percentage of approximately 80-90%. This makes it an ideal material for various applications where reflective properties are desired, such as in the manufacturing of mirrors, solar panels, and lighting fixtures. The high reflectivity of aluminum coils allows for efficient light reflection, minimizing energy loss and maximizing the performance of these applications.

- Q: Is it possible to utilize a grinder for cutting aluminum coils?

- <p>Yes, you can use a grinder to cut aluminum coils, but it's important to use the right type of grinder and accessories. An angle grinder with a cutting wheel or a metal cutting disc is suitable for this task. Ensure the grinder is equipped with a safety guard and that you're wearing appropriate safety gear, such as goggles and gloves. Be cautious as aluminum can be slippery and the grinder can generate a lot of heat, which may require frequent cooling to prevent the disc from burning out. It's also advisable to work in a well-ventilated area due to the fine particles produced during cutting.</p>

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

- Q: What are the potential fire hazards associated with aluminum coils?

- There are several potential fire hazards associated with aluminum coils. First and foremost, aluminum is a highly flammable material, which means it can catch fire easily and burn quickly. This poses a significant risk if there is an ignition source nearby, such as an open flame, electrical spark, or hot surface. Another potential fire hazard is the accumulation of dust, dirt, or other combustible materials on the aluminum coils. These substances can act as fuel for a fire, increasing the likelihood and intensity of combustion. It is important to regularly clean and maintain the coils to prevent the buildup of such materials. Aluminum coils are often used in HVAC systems, and if these coils are not properly installed or maintained, they can become a fire hazard. For instance, if the coils are not securely fastened or if there are loose electrical connections, it can lead to overheating and potentially cause a fire. Additionally, aluminum coils can cause electrical fires if they come into contact with live electrical wires or if there is a short circuit. This can happen if the coils are installed too close to electrical components or if there is a failure in the insulation or grounding of the system. Lastly, the use of flammable refrigerants in HVAC systems can also increase the fire risk associated with aluminum coils. If there is a leak or malfunction in the refrigerant system, it can create a flammable atmosphere around the coils, leading to a potential fire or explosion. To mitigate these fire hazards, it is crucial to follow proper installation guidelines, regularly inspect and maintain the coils, keep the surrounding area clean and free from combustible materials, and ensure that there are no electrical or refrigerant leaks in the system. It is also recommended to have fire detection and suppression systems in place to quickly respond to any potential fire emergencies.

Send your message to us

Aluminum Coil suppliers Wholesale in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords