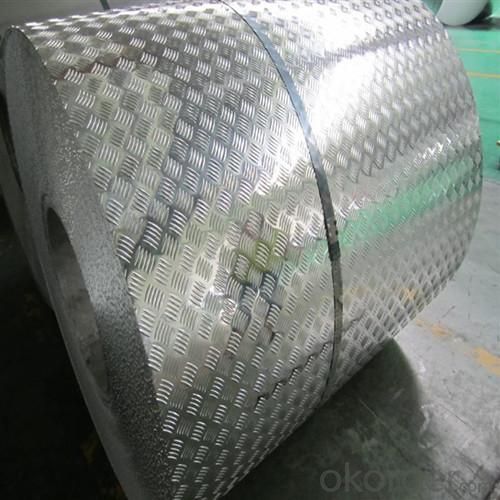

Diamond Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Diamond Embossed Coated Aluminium Coil

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Uage/Application of Diamond Embossed Coated Aluminium Coil and Sheet

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Diamond Embossed Coated Aluminium Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

Shipment: The goods will be delivered in not more than 40 days after getting the buyer's payment.

4. Production Flow of Diamond Embossed Coated Aluminium Coil

Melting-Rolling- Cutting- Annealing--Packing

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for pharmaceutical packaging due to its various beneficial properties. It is lightweight, corrosion-resistant, and has excellent barrier properties, making it ideal for protecting pharmaceutical products from external factors such as moisture, oxygen, and light. Aluminum coils can be easily formed into different shapes and sizes, providing versatility for packaging needs. Additionally, aluminum is non-toxic and non-reactive, ensuring the safety and integrity of pharmaceutical products.

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: What are the different tempers available for aluminum coils?

- Aluminum coils have various tempers available, each with its own unique characteristics and properties. Let's explore the most common tempers: 1. O Temper, also known as annealed or soft temper, is the softest and most ductile option. It has low strength but high formability, making it ideal for applications that involve extensive forming or bending. 2. The H temper series includes different levels of work hardening, resulting in increased strength and reduced formability compared to the O temper. The H temper range consists of H1X, H2X, H3X, H4X, H5X, and H6X, with each subsequent number indicating a higher level of work hardening. These tempers are commonly used when moderate to high strength is required. 3. The T temper series, also known as heat-treated tempers, involves thermal treatments to achieve a specific combination of strength and formability. The most common T tempers are T3, T4, T6, and T7. T3 and T4 are solution heat-treated and naturally aged, offering a good balance of strength and formability. T6 and T7 are solution heat-treated and artificially aged, resulting in higher strength but reduced formability. 4. The F temper, also known as as-fabricated temper, is obtained through hot or cold working without subsequent thermal treatments. It provides improved strength and hardness compared to the O temper but is lower than the H and T tempers. These various tempers enable the use of aluminum coils in a wide range of applications, including automotive parts, aerospace components, building materials, and consumer goods. The choice of temper depends on the specific requirements of the application, such as desired strength, formability, and corrosion resistance.

- Q: What are the common surface finishes for aluminum coils in the automotive industry?

- In the automotive industry, aluminum coils are widely used for various applications due to their lightweight, high strength, and corrosion resistance properties. To enhance their appearance and protect them from environmental factors, aluminum coils in the automotive industry often undergo surface finishes. One of the most common surface finishes for aluminum coils in the automotive industry is anodizing. Anodizing is an electrochemical process that creates a thin protective layer on the surface of the aluminum coil. This finish not only provides excellent corrosion resistance but also allows for color customization, making it a popular choice for automotive applications. Anodized aluminum coils can be found in various colors and finishes, adding aesthetic appeal to the vehicles. Another commonly used surface finish for aluminum coils in the automotive industry is powder coating. Powder coating involves applying a dry powder paint onto the surface of the aluminum coil and then curing it under heat to create a durable, long-lasting finish. Powder coating provides excellent resistance to chipping, scratching, and fading, making it ideal for automotive components that are exposed to harsh conditions and require a high level of durability. Additionally, powder coating offers a wide range of color options, allowing manufacturers to achieve the desired aesthetic appearance. Furthermore, aluminum coils in the automotive industry may also undergo other surface finishes such as laminating, painting, or polishing, depending on the specific application requirements. Laminating involves bonding a thin protective film onto the surface of the aluminum coil to provide additional protection against abrasion and chemical exposure. Painting involves applying liquid paint onto the surface of the aluminum coil, allowing for customization and protection against corrosion. Polishing is a mechanical process that enhances the surface smoothness and appearance of the aluminum coil, providing a reflective and shiny finish. In summary, the common surface finishes for aluminum coils in the automotive industry include anodizing, powder coating, laminating, painting, and polishing. These finishes not only enhance the appearance of the aluminum coils but also provide protection against corrosion, abrasion, and other environmental factors, making them essential in the manufacturing of automotive components.

- Q: How do aluminum coils contribute to lightweight construction?

- Aluminum coils play a crucial role in lightweight construction due to the inherent properties of aluminum as a metal. Aluminum is known for its low density, which means it is significantly lighter than other metals such as steel or copper. When aluminum is formed into coils, it allows for a greater surface area and, therefore, more efficient heat transfer and distribution. By utilizing aluminum coils in various applications, such as in the automotive, aerospace, and construction industries, the overall weight of the structure or product is significantly reduced. This reduction in weight offers several advantages, including improved fuel efficiency in vehicles, increased payload capacity in aircraft, and easier handling and installation in construction projects. Furthermore, the lightweight nature of aluminum coils enables designers and engineers to create more innovative and energy-efficient designs. With less weight to support, it becomes possible to use thinner and lighter materials for other components, leading to additional weight savings. This can result in cost savings during manufacturing and transportation, as well as reduced environmental impact. Moreover, aluminum coils are highly corrosion-resistant, which makes them ideal for outdoor applications. Their resistance to rust and corrosion adds to their durability and longevity, ensuring that lightweight structures made with aluminum coils can withstand harsh environmental conditions. In summary, aluminum coils contribute to lightweight construction by providing a lightweight, yet strong and durable material. This enables designers and engineers to create more efficient and sustainable structures, vehicles, and products. The use of aluminum coils not only reduces the weight of the overall construction but also offers benefits such as improved fuel efficiency, increased payload capacity, and cost savings.

- Q: Please tell me the model of antirust aluminium coil, it is better to have a detailed introduction. Thank you。 Shandong production of rust resistant aluminum coil manufacturers

- We are Ji'nan excellent Aluminum Co., Ltd., anti rust aluminum roll, now domestic generally use 3003 material, the price is now 19500 yuan / ton.3003 aluminum coil for AL-Mn alloy, is the most widely used of a rust resistant aluminum, density is 2.73.

- Q: How do aluminum coils compare to copper coils?

- Coils made of aluminum and copper are commonly used in various applications, including heating, ventilation, and air conditioning (HVAC) systems. While aluminum and copper have their own advantages and disadvantages, there are notable distinctions between the two types of coils. First and foremost, cost is a significant factor. Generally speaking, aluminum is cheaper than copper, making it a more cost-effective option for specific applications. However, it is important to acknowledge that the cost of copper has decreased in recent years, resulting in a narrower price difference between the two materials. Another distinguishing feature is heat transfer efficiency. Copper is a better conductor of heat compared to aluminum, which means that copper coils have superior heat transfer capabilities. This leads to more efficient cooling or heating, resulting in lower energy consumption and potentially reduced operating costs. Conversely, aluminum coils have a higher thermal expansion rate, which can cause increased stress on the system over time. Durability is another aspect to consider. Copper is renowned for its durability and resistance to corrosion, making copper coils more reliable and long-lasting. On the contrary, aluminum is more susceptible to corrosion, particularly in areas with high humidity or exposure to saltwater. Nevertheless, advancements in coating technologies have enhanced the corrosion resistance of aluminum coils, making them suitable for numerous applications. Lastly, the weight of the coils is worth mentioning. Aluminum coils are significantly lighter than copper coils, making them easier to handle and install. This can be advantageous in situations where weight is a concern, such as in mobile or portable HVAC units. In conclusion, aluminum coils and copper coils possess their own distinctive characteristics and advantages. Aluminum coils are generally more cost-effective and lighter, but may have lower heat transfer efficiency and be more susceptible to corrosion. Copper coils, on the other hand, offer superior heat transfer, improved durability, and resistance to corrosion. The choice between the two materials ultimately depends on the specific requirements and priorities of the application.

- Q: Can aluminum coils be used in the production of automotive heat shields?

- Yes, aluminum coils can be used in the production of automotive heat shields. Aluminum is commonly used in heat shields due to its excellent thermal conductivity and lightweight properties. It helps to effectively dissipate and reflect heat, making it a suitable material for this application.

- Q: Are aluminum coils suitable for architectural sunshades?

- Yes, aluminum coils are suitable for architectural sunshades. Aluminum is a popular material choice for sunshades due to its lightweight nature, durability, and corrosion resistance. Aluminum coils can be used to create various shapes and designs for sunshades, allowing for flexibility in architectural design. Additionally, aluminum can be easily fabricated and installed, making it a practical choice for architectural projects. Furthermore, aluminum has excellent thermal properties, allowing it to effectively reflect heat and reduce solar gain, which can help improve energy efficiency in buildings. Overall, aluminum coils are a suitable and versatile option for architectural sunshades.

- Q: Can aluminum coils be used in the production of heat sinks?

- Yes, aluminum coils can be used in the production of heat sinks. Aluminum is a popular material for heat sinks due to its excellent thermal conductivity and low cost. Heat sinks are used to dissipate heat from electronic components such as processors, power transistors, and LED lights. The coils can be manufactured into various shapes and sizes to meet specific heat dissipation requirements. Additionally, aluminum is lightweight, corrosion-resistant, and easily available, making it an ideal choice for heat sink production.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Diamond Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords