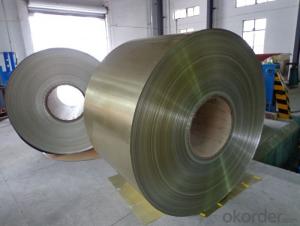

Customized Coated Aluminum Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum plate/sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: Why there is arc panel after aluminum coil straightening?

- The aluminum coil can only become flat and straight after being planished on stretch bender.

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils possess unique properties and advantages, allowing them to be employed in a wide range of potential applications. Here are some of the primary areas where they can be utilized: 1. Architectural: The distinct properties of coil-anodized aluminum make it well-suited for architectural purposes, including cladding, roofing, and facades. With its anodized coating, it offers increased durability, resistance to weather conditions, and color stability, making it suitable for outdoor use in various climates. Furthermore, the coils can be shaped and formed to create different architectural elements, providing design flexibility. 2. Transportation: Due to its lightweight nature, coil-anodized aluminum is ideal for transportation applications. It can be employed in the manufacturing of parts and components for the automotive, aerospace, and marine industries. The anodized coating enhances its corrosion resistance, making it suitable for exterior components and structures. 3. Electronics: Coil-anodized aluminum coils find utility in the field of electronics manufacturing. The anodized coating provides excellent electrical insulation, which is crucial in applications necessitating high conductivity and insulation. It can be utilized in the production of components such as heat sinks, casings, and connectors. 4. Signage and displays: The vibrant and long-lasting colors achieved through coil-anodizing make it a perfect material for signage and displays. The anodized coating ensures color stability against UV radiation and harsh weather conditions, rendering it suitable for both indoor and outdoor applications. It enables the creation of eye-catching and durable signage and displays. 5. Furniture and interior design: Coil-anodized aluminum coils can be employed in the manufacture of furniture and interior design elements. The anodized coating provides a smooth, durable, and scratch-resistant surface, making it suitable for applications like tables, chairs, wall panels, and decorative elements. The wide range of available colors and finishes allows for versatile design possibilities. 6. Industrial applications: Coil-anodized aluminum coils can be utilized in diverse industrial sectors. The anodized coating offers enhanced corrosion resistance, which is advantageous in industries such as chemical processing, food processing, and pharmaceuticals. It can be used in the production of tanks, containers, and equipment that require resistance against harsh chemicals and environments. 7. Energy and sustainable applications: The lightweight nature and durability of coil-anodized aluminum make it suitable for energy and sustainable applications. It can be employed in the manufacturing of solar panels, heat exchangers, and other energy-related components. The anodized coating provides protection against weathering and corrosion, ensuring long-term performance. In conclusion, coil-anodized aluminum coils have extensive and diverse potential applications, spanning across architectural, transportation, electronics, signage, furniture, industrial, and energy sectors. The combination of its lightweight nature, durability, color stability, and corrosion resistance makes it a versatile material for various industries and applications.

- Q: What are the proper storage methods to maintain the quality of aluminum coil for future use?

- <p>To store aluminum coil for future use, ensure it is kept in a cool, dry place away from direct sunlight and moisture. Stack the coils on flat, level surfaces with appropriate padding to prevent damage. Avoid stacking with other metals to prevent galvanic corrosion. Use clean, dry hands or gloves when handling to prevent oil and dirt from contaminating the surface. Store in a controlled environment with a relative humidity below 65% and a temperature between 32掳F to 90掳F (0掳C to 32掳C). Regularly inspect the coils for any signs of corrosion or damage.</p>

- Q: is there any kind of solder or technique that can solder copper to aluminium? or is it just not possible!?

- Not using solder or other alloys of tin and lead. However, brazing may be possible. But you will need someone skillful.

- Q: Can aluminum coils be used for marine applications?

- Yes, aluminum coils can be used for marine applications. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance in saltwater environments. It has a natural oxide layer that forms on its surface, providing protection against corrosion. Aluminum coils are commonly used for marine applications such as boat hulls, decks, and structures. Additionally, aluminum is lightweight, which contributes to fuel efficiency and improved performance in marine vessels. Its high strength-to-weight ratio makes it an ideal choice for constructing boats and other marine equipment. However, it is important to select the appropriate grade of aluminum alloy that is specifically designed for marine applications to ensure optimal performance and longevity.

- Q: remember maybe a decade ago or so, copper used to be cheaper than aluminum. now it is the other way around, copper is more expensive. Even copper pennies cost more so I heard they are mixed with another metal to make a penny. What caused the change in value and when did it really start happening?In fact, copper has become valuble enough to steal. Some factories which have copper, have had their metals stolen, but outsiders who break into the factories to specifically take the copper. Then the factories started hiring security to prevent intruders from taking the copper.

- The two metals are a long way apart on the electro-chemical scale. This means that if they come into contact, a small - but significant - voltage will exist between them - completely independent of what currents are actually in the wires. This small voltage causes corrosion of both metals: not good!

- Q: Can aluminum coils be used for gutter systems?

- Indeed, gutter systems can employ aluminum coils. The lightweight property, durability, and resistance to rust and corrosion make aluminum a favored material for gutters. It is common practice to utilize aluminum coils to shape seamless gutters, which present benefits such as reduced leakage and an enhanced visual appeal. Moreover, maintaining aluminum gutters is effortless, and they can be painted to harmonize with a building's exterior. All in all, aluminum coils are a fitting and frequently employed option for gutter systems.

- Q: Can aluminum coils be used in automotive manufacturing?

- Automotive manufacturing can indeed utilize aluminum coils. Aluminum, a versatile and lightweight substance, presents several advantages within the automotive sector. Frequently employed for fabricating components such as body panels, engine blocks, wheels, and heat exchangers, aluminum's incorporation in automotive manufacturing enhances fuel efficiency by reducing vehicle weight and subsequently minimizing energy consumption. Furthermore, aluminum boasts exceptional resistance to corrosion, rendering it appropriate for deployment in diverse weather conditions. In conclusion, the extensive benefits associated with the utilization of aluminum coils in automotive manufacturing have led to its widespread adoption by numerous car manufacturers.

- Q: What are the density and specific gravity values of aluminum coils?

- The density of aluminum coils is approximately 2.7 g/cm³, and the specific gravity value is approximately 2.7.

- Q: Can aluminum coils be used for solar panel applications?

- Solar panel applications can utilize aluminum coils, which are lightweight and durable materials commonly employed in solar panel construction. Aluminum, an excellent conductor of electricity, is ideal for capturing and conducting solar energy. These coils can serve as backing materials for solar panels, offering structural support and aiding in heat dissipation. Furthermore, aluminum possesses good corrosion resistance, a crucial characteristic for solar panels exposed to diverse weather conditions. Ultimately, the strength, conductivity, and corrosion resistance of aluminum coils render them a favored choice for solar panel applications.

Send your message to us

Customized Coated Aluminum Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords