Coated and Stucco Embossed Aluminium Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Coated and Stucco Embossed Aluminium Coils for Refrigerator

Our coated and stucco embossed aluminium coils are widely used in regrigerators, ice-boxes, cold storage, freezer, etc.

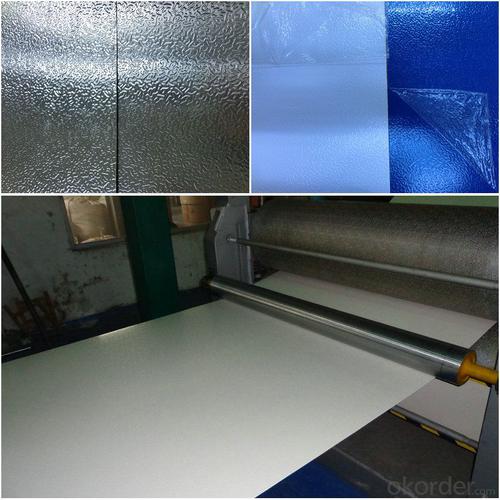

We normally use 3105, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of Coated and Stucco Embossed Aluminium Coils for Refrigerator

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

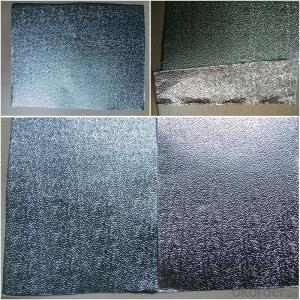

3. Coated and Stucco Embossed Aluminium Coils for Refrigerator Images

4. Specification of Coated and Stucco Embossed Aluminium Coils for Refrigerator

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

Is Aluminium Foil Safe to Use?

It just seems like yesterday when I was a little girl and my mom would pack a parantha in a tea towel and send it with me to my school for lunch. I loved the way the lunch was packed which never spilled a drop of oil and never messed my school bag. The years saw a new trend approaching. The tea towels were replaced by Aluminum Foil, as it was believed to keep the food warm, fresh and avert any spillage. Of course, we as a kid loved it, not that it mattered to us but we could crush the aluminum foil into a ball after finishing our lunch and play recklessly at the break. Unfortunately playing with it was the only legitimate and safe use of Aluminum foil. Now when I look back I realize how limited was our knowledge. We were unaware as to how unsafe it is to wrap the food with aluminum foil especially when it is hot.

A study showed that increasing level of aluminum in our food and life leads to brain and bone damage. The scary truth about aluminum is that it is found in so many things in our world and it is toxic to our bodies, even in small amounts. From household products to vaccinations, aluminum pervades our lifestyle, and if not monitored closely, can easily make its way into our bodies causing lasting, harmful effects. The researchers found dangerously high levels of aluminum in foods after being cooked, reheated, and even cooked in aluminum foil. If food is cooked on high temperature wrapped in the aluminum foil the aluminum leaches into your food and then in turn in your body. The cause for alarm is that when aluminum accumulates in the body, it can lead to osteoporosis and Alzheimer's.

Now over the passage of years when I have become a mother myself I want to see my kid grow up safe in the healthy environment. Although I cannot eliminate aluminum out of our lives completely but I can determine how to avoid it to the maximum. Then the question arises are there any viable substitutes for aluminum? What is that we can do to protect our food from getting toxic? These are some of the practices if followed can make our food stay safe.

Never cook, heat up, or place hot food on aluminum foil. You can use tempered glass containers to do that or more economic would be to use food wrapping paper or parchment paper instead.

Avoid storing tomatoes, citrus fruits, or spices in foil. As mentioned above food wrapping paper keeps the wrapped food fresh and doesn't contaminate it.

Never use aluminum pots or cooking utensils. Instead, invest in stainless steel pots and pans. You can even use seasoned cast iron skillets or pots or even stoneware as a substitute to aluminum pans.

Banana leaves have been considered as the most healthy and natural way of storing, cooking and reheating food. If you can easily find it in your vicinity it can be the best substitute of aluminum foil.

While baking use of aluminum foil can be avoided if you line your baking sheet with parchment paper to bake your cookies or even roast your veggies and poultry.

If you need to cover your food while or after baking then again parchment paper is the answer, it doesn't let your food become dry and saves it from splashing all over the oven.

I can't undo my past but I know for sure that the future of my family lies in my hands. I can pretend to be ignorant or simply callous but ultimately the loss is mine. It's better we adopt healthy and safe food practices like eliminating the use of aluminum foil from our lives and embracing ways like use of banana leaves or food wrapping paper. Don't wait, start today!

- Q: Other than alloys. I'm trying to think of a way I can make an aluminum knife that will hold an edge. One group of researches say they used 60 metric tons of force to realign the molecular structure and give the metal strength equal to steel. I don't have a 60 ton press aha. Would heat treatment plus 10 tons of pressure repeated have a similar affect?

- Aluminum bronze is used commercially to make non-sparking knives. Why try to reinvent the wheel? I'm trying to think of a way I can make an aluminum knife that will hold an edge. You can strengthen aluminum by either cold working or heat treating a suitable alloy, but it will never be anything close to a good steel knife. Would heat treatment plus 10 tons of pressure repeated have a similar affect? No. Assuming that you are talking about the article linked to below: - you would have to duplicate the alloy process, even then you could only make a small thin sheet. They used a heat treatable alloy. The process involves torsional strain under 60 metric tons per square centimeter compression. How big a press do you think you would need for a knife size blank? And remember, you have to apply torsional cold work while compressing it. -Their results ( 1 gPA YS 5% elongation in a very thin sheet) don't look that great compared to a good knife steel. Or a good titanium knife.

- Q: I have a broken exhaust stud in my engine head. I have an aluminum head but the stud is steel. The stud broke a little below the surface. I want to mig weld a washer to the stud, but will the weld stick to the aluminum or will it blow a big hole in the head? I will only be using a little 110 mig welder.will I be okay or will that lead to more problems?

- Drill out the stud, extract the broken stud, refresh the threads and install a new stud. You'll ruin the head if you attempt to weld.

- Q: Can aluminum coils be used for seamless gutters?

- Seamless gutters can indeed utilize aluminum coils. The reason aluminum is favored for gutter systems is its ability to withstand wear, its lightweight composition, and its resistance to rust. Aluminum coils are frequently employed in the construction of seamless gutters, which boast several advantages over the more traditional sectional gutters. Custom-made on-site, seamless gutters guarantee a flawless fit for the specific measurements of a structure. This eliminates the necessity for seams, which are susceptible to leaks and require regular maintenance. Moreover, aluminum is malleable, making it easy to shape seamless gutters to accommodate a building's unique design. In summary, aluminum coils present a practical and efficient option for the creation of seamless gutters.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. In fact, aluminum coils have become increasingly popular in recent years due to their numerous advantages over traditional copper coils. Aluminum coils are lighter, more durable, and more resistant to corrosion. They also have excellent heat transfer properties, allowing for efficient cooling of the refrigerant. Additionally, aluminum coils are more cost-effective and environmentally friendly compared to copper coils. Overall, using aluminum coils for HVAC condenser coils is a viable and beneficial option.

- Q: What are the potential applications of coil-laminated aluminum coils?

- Coil-laminated aluminum coils have a wide range of potential applications in various industries. They can be used in the manufacturing of automotive parts, such as body panels and interior components, due to their lightweight yet durable nature. Additionally, they are suitable for building and construction purposes, including roofing, siding, and insulation, as they offer excellent corrosion resistance and thermal conductivity. Furthermore, coil-laminated aluminum coils find use in electrical industries for producing transformers, capacitors, and other electrical components due to their excellent electrical conductivity. Overall, their versatility and desirable properties make coil-laminated aluminum coils valuable in numerous applications across different sectors.

- Q: Can aluminum coils be used in kitchen appliances?

- Yes, aluminum coils can be used in kitchen appliances. Aluminum is a commonly used material in the manufacturing of kitchen appliances due to its excellent thermal conductivity and corrosion resistance. It is often used in refrigerators, air conditioners, and other appliances that require efficient heat transfer. Aluminum coils are lightweight, durable, and can effectively dissipate heat, making them suitable for use in various kitchen appliances.

- Q: Is it safe for individuals to handle aluminum coils?

- <p>Aluminum coils are generally safe to handle under normal conditions. They do not emit harmful radiation or toxic fumes. However, it's important to take precautions to avoid injury from sharp edges or heavy weight. Always use appropriate lifting equipment or assistance when handling heavy coils. Additionally, wear protective gloves to prevent cuts and ensure good housekeeping to avoid tripping hazards. In case of skin contact with certain aluminum processing fluids, it's advisable to wash the affected area immediately with soap and water.</p>

- Q: Are aluminum coils suitable for construction applications?

- Yes, aluminum coils are suitable for construction applications. They are lightweight, durable, and corrosion-resistant, making them an ideal choice for various construction purposes such as roofing, siding, and insulation. Additionally, aluminum coils can be easily formed and shaped, providing flexibility in design and installation.

- Q: What are the different types of surface defect classifications for aluminum coils?

- There are several types of surface defect classifications for aluminum coils. These classifications are used to categorize and identify various imperfections that can occur on the surface of aluminum coils during the manufacturing process. Some common types of surface defects include: 1. Scratches: These are linear marks or grooves on the surface of the aluminum coil. Scratches can vary in depth and length and are typically caused by mechanical friction or handling during production or transportation. 2. Streaks: Streaks are discolorations or lines that appear on the surface of the coil. They are often caused by uneven coating or impurities in the aluminum material. 3. Dents: Dents are depressions or distortions on the surface of the coil. They can be caused by mishandling, impact, or improper storage of the coils. 4. Pitting: Pitting refers to the presence of small, localized holes or craters on the coil surface. It is often caused by the corrosion of the aluminum, exposure to aggressive environments, or improper surface treatment. 5. Surface contamination: This classification includes any foreign substances or contaminants that are present on the surface of the aluminum coil. Examples of surface contaminants can include oil, dirt, dust, or residues from the manufacturing process. 6. Oxide films: Oxide films are thin layers of aluminum oxide that can form on the surface of the coil. These films can vary in thickness and appearance and are often a result of exposure to air or moisture. It is important to classify and identify these surface defects accurately as they can affect the quality and performance of the aluminum coils. Manufacturers and customers use these classifications to determine the acceptability of the coils and make decisions regarding their usability and potential treatment or repair.

- Q: What are the different types of aluminum coils available in the market?

- There are several types of aluminum coils available in the market, including painted aluminum coils, embossed aluminum coils, anodized aluminum coils, and mill finish aluminum coils. Each type has its own unique characteristics and uses, catering to various industries and applications.

Send your message to us

Coated and Stucco Embossed Aluminium Coils for Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords