Color Coated Aluminum Coil with Various Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil with Various Thickness

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

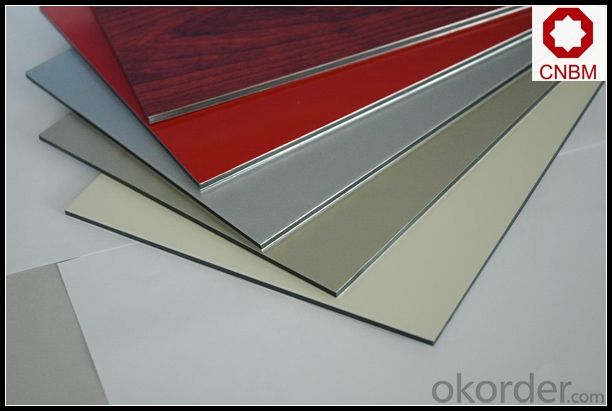

2. Application of Color Coated Aluminum Coil with Various Thickness

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil with Various Thickness

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

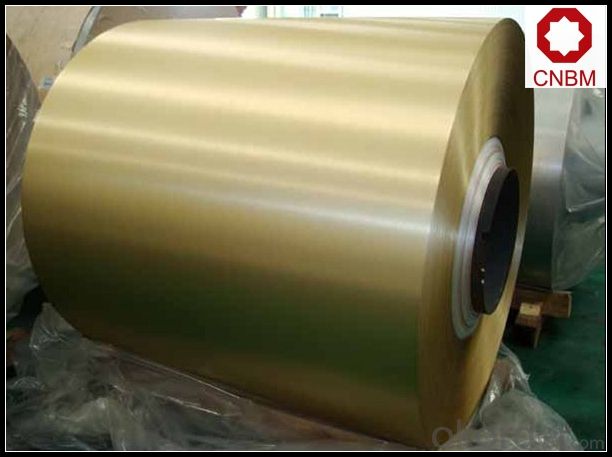

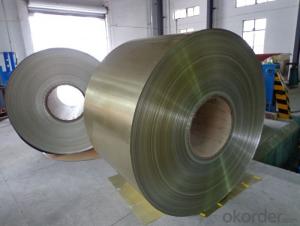

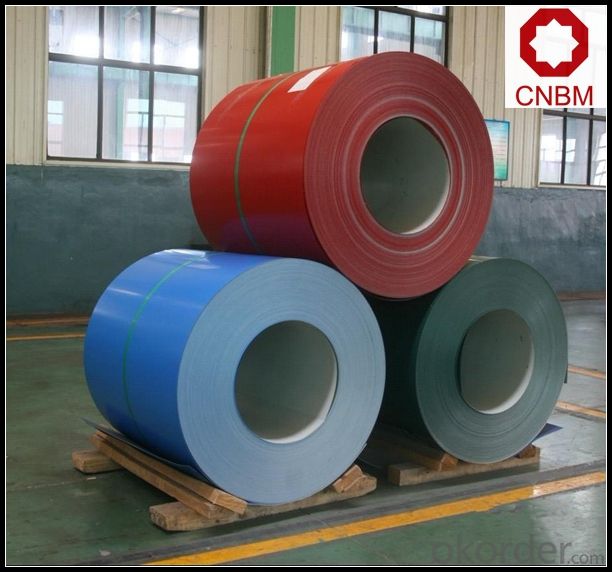

5. Image of Color Coated Aluminum Coil with Various Thickness

6. Package and shipping of Color Coated Aluminum Coil with Various Thickness

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils possess a multitude of possible uses across various industries. The construction industry heavily relies on anodized aluminum coils, utilizing them for cladding and façade systems. The anodized coating enhances the aluminum's durability, weather resistance, and aesthetic appeal. Its ability to withstand harsh environmental conditions, such as UV radiation, saltwater exposure, and extreme temperatures, makes it an optimal choice for building exteriors. The automotive industry also benefits significantly from anodized aluminum coils. The anodized coating adds a protective layer that enhances the aluminum's corrosion resistance, making it suitable for a wide range of automotive components. These coils can be used for trim, body panels, window frames, and other parts that require both durability and an attractive appearance. Consumer electronics manufacturing also utilizes anodized aluminum coils due to their scratch resistance, electrical insulation, and heat dissipation properties. The anodized coating makes it suitable for electronic enclosures, heat sinks, and connectors. Moreover, the ability to achieve vibrant colors through anodization allows for customizable designs that appeal to consumers. The heating, ventilation, and air conditioning (HVAC) industry extensively uses anodized aluminum coils due to their lightweight nature and excellent heat conductivity. Heat exchangers, air conditioning coils, and evaporator coils commonly utilize these coils. The anodized coating provides protection against corrosion caused by moisture and other environmental factors, ensuring the longevity and efficiency of these HVAC components. Furthermore, the food and beverage industry finds applications for anodized aluminum coils due to the hygienic surface provided by the anodized coating. It is easy to clean and resistant to bacterial growth, making it suitable for food processing equipment, storage tanks, and packaging materials. This ensures the safety and quality of the products. In conclusion, anodized aluminum coils possess vast and diverse potential applications, ranging from construction and automotive to electronics and food processing. The unique combination of durability, corrosion resistance, heat dissipation, and aesthetic appeal makes anodized aluminum coils a versatile material that finds use in numerous industries.

- Q: Can aluminum coils be used for packaging applications?

- Yes, aluminum coils can be used for packaging applications. Aluminum is a lightweight and durable material that is commonly used in various packaging applications due to its excellent barrier properties, resistance to corrosion, and ability to be easily formed into different shapes. It is commonly used for packaging food and beverages, pharmaceutical products, and many other consumer goods.

- Q: Why 5052 turn black after annealing during the production of aluminum alloy?

- The aluminum oxide in the surface has been oxidized by other chemical elements.

- Q: Aluminum is a metal and nitrate (nitrogen) is a non metal so shouldn't they form an ionic bond and not a covalnt bond? And if it were an ionic bond wouldn't it be called aluminum mononitrate? But it is a covalnt bond (thus a molecular bond and so there is no mono in the name). Pleas help I'm very confused!

- You have the advantage here. As far as I know, the compound is ionic with one Al^+3 ion and three NO3^-1 ions. There have to be 3 negative ions to balance the charge of +3 on the aluminum ion to make a neutral formula unit

- Q: What are the different coil slitting options available for aluminum coils?

- There are several coil slitting options available for aluminum coils, including rotary slitting, oscillating slitting, and multi-blade slitting. These methods allow for precise and efficient cutting of the aluminum coils into narrower widths, making them suitable for various applications in industries such as automotive, construction, and packaging.

- Q: This question asks for methods to assess the quality of aluminum coils, which is important for various industries that use aluminum for manufacturing and construction.

- <p>To check the quality of aluminum coils, you should inspect for surface defects such as scratches, dents, or discoloration. Measure the thickness and width to ensure they meet specifications. Test the hardness and tensile strength to verify mechanical properties. Conduct a chemical analysis to confirm the alloy composition. Check for internal defects using non-destructive testing methods like ultrasonic testing. Assess the coil's flatness and straightness to prevent issues in further processing. Finally, ensure proper packaging and storage conditions to maintain coil quality.</p>

- Q: How to purchase PE polyester coated aluminum sheet and PVDF fluorocarbon coated aluminum coil?

- Both belong to color coated aluminum sheet and coil. Customers can purchase ordinary aluminum sheet or coil, and then go to special coating company to add PE polyester coating or PVDF fluorocarbon coating. The color is bright and quality is also very good. PE polyester coated aluminum and PVDF fluorocarbon coated aluminum coil has a wide range of usages: construction industry (aluminum-plastic panel, aluminum honeycomb, roof corrugated sheet, fireproof veneer, aluminum ceiling, shutter, rolling shutter door, garage door, awning, water gutter), electronic appliances (computer chassis, computer panel), lighting, furniture, solar reflector, air conditioning duct and the like. At present it is still applied in many areas including electronic appliance, instrument, lighting, packaging and house decoration.

- Q: How are aluminum coils protected against scratches and damage?

- Aluminum coils are protected against scratches and damage through various methods such as applying protective coatings, using protective films, and implementing proper handling and packaging techniques during transportation and storage.

- Q: I bought some cheap aluminum foil, but one weighs much less than the other brand for the same thickness and length, why?What is the other made of? Is it still good to use for grounding something?Thank you.

- Aluminum foil is aluminum foil, it has nothing but aluminum in it. One of them is misstating the thickness, or you are mistaken about the weight or width.

- Q: Is it safe to use aluminum coils in various applications?

- <p>Yes, aluminum coils are generally safe to use. They are widely used in various industries due to their excellent thermal conductivity, corrosion resistance, and lightweight properties. Aluminum coils are non-toxic and do not emit harmful substances, making them safe for applications such as food packaging and construction. However, safety can depend on specific uses and manufacturing processes, so it's important to ensure that the coils meet the required safety standards for their intended application.</p>

Send your message to us

Color Coated Aluminum Coil with Various Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords