Cold rolled aluminum coil 0.15-4.0mm 1060 1100 3003 3105 5052 Aluminum alloy coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

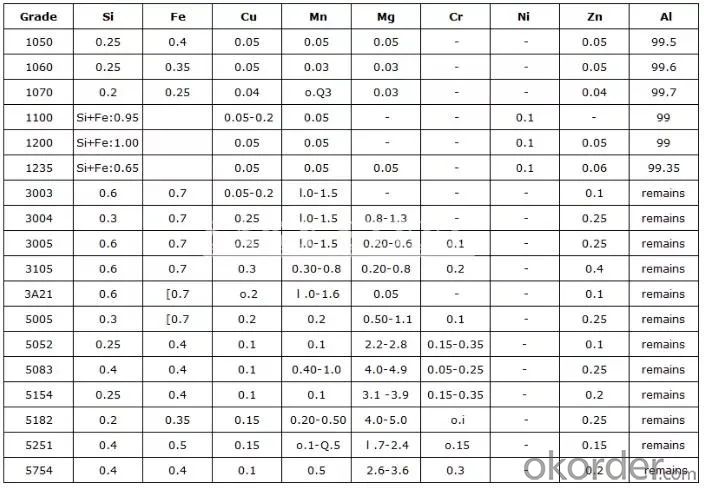

Specification

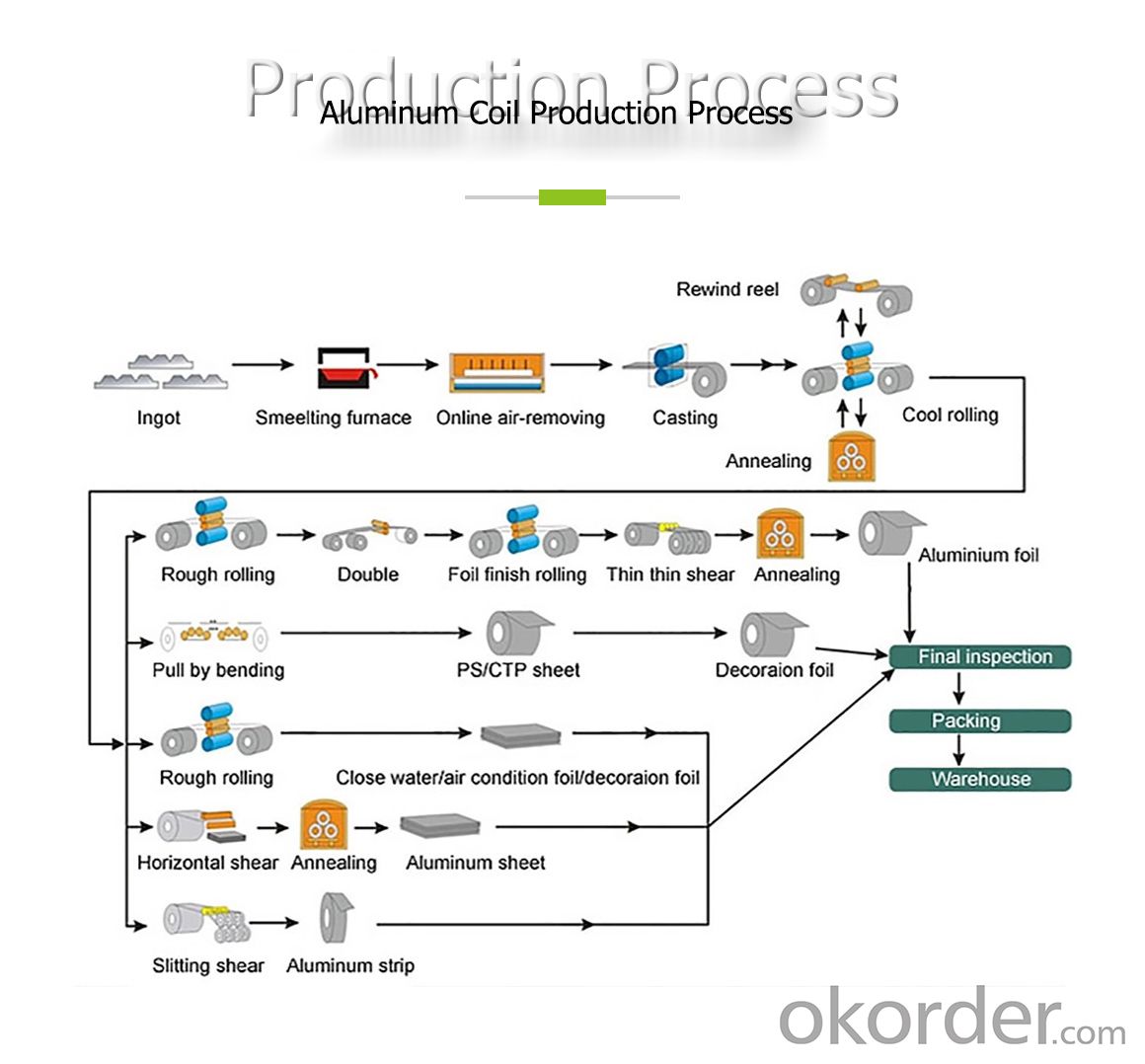

Cold rolled aluminum coil usually refers to the cold rolled aluminum coil processed by the cast rolling material through the cold rolling process, which is usually called cast rolled aluminum coil. Cold rolling is a common metal processing process. It is to reduce the thickness of the material and improve its surface quality and mechanical properties by further processing at room temperature or slightly below room temperature after the metal is heated (usually hot rolled). As for the aluminum coil casting process, it may be relatively simple. Aluminum ingot---aluminum liquid---static furnace---cast rolled coil, which is a conventional processing process for raw materials.

Cold-rolled aluminum coils are more inclined to non-heat treatment processes. For example, our common 1060 aluminum coils, 3003 aluminum plates, 3105 aluminum coils, 5052 aluminum plates, 1100 aluminum plates, etc. are all cold-rolled aluminum coils, which are suitable for simple stamping, but not suitable for large-scale finished product stamping. Therefore, the main application areas are currently mainly concentrated in building exterior walls, signs and signs, etc.

Aluminum coil specifications:

| Alloy | 1060, 1100, 3003, 3004, 3105, 5052, 8011, etc |

| Temperature | H32 H34 H36 H42 H111 H112 H116, etc |

| Surface | Mill, Bright, Polished, Hairline, Embossed, Etching |

| Thickness | 0.15-4.0mm |

| Width | 20-2650mm |

| Length | C |

| Core Diameter | 505/508 |

| Sample | Free sample |

Features of cold-rolled aluminum coil:

1. High surface finish: The cold rolling process can improve the surface quality of the aluminum coil, making it smooth and shiny.

2. High thickness accuracy: The thickness of the cold-rolled aluminum coil can be very precise, suitable for applications with strict thickness requirements.

3. Excellent mechanical properties: The cold rolling process can improve the strength and hardness of aluminum, especially in applications that require high strength.

4. Good processability: Due to its good strength and ductility, cold-rolled aluminum coils are easy to process in the future, such as shearing, stamping, stretching, etc.

Application areas:

Building materials: used for building materials such as roofs, wall panels, curtain walls, etc.

Automotive industry: body panels, auto parts, etc.

Electronic products: shells of mobile phones, laptops, etc.

Home appliance industry: shell materials for home appliances such as refrigerators and washing machines.

Packaging industry: such as beverage cans, food packaging, etc.

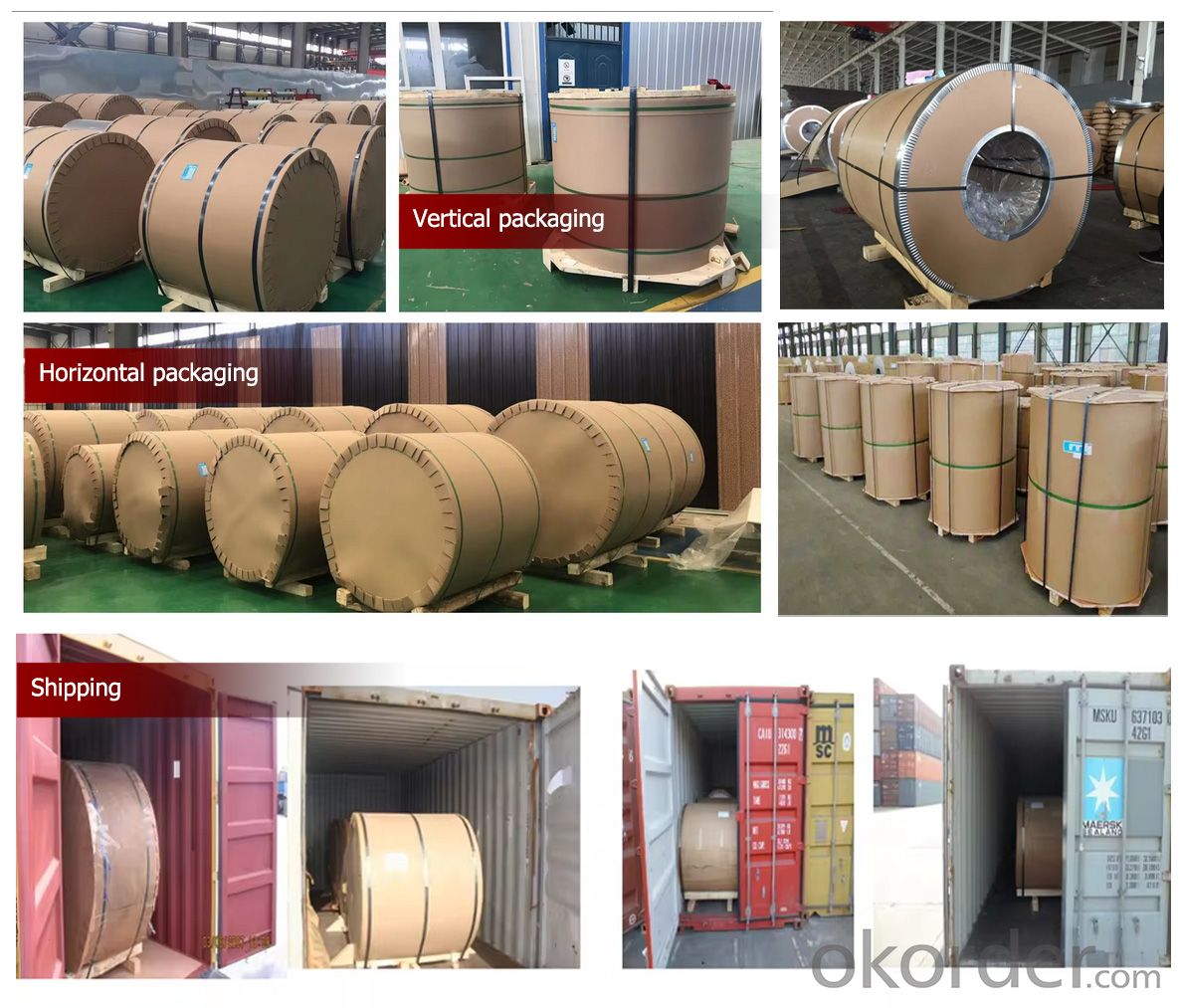

Packaging:

Export packaging of aluminum coils: Export packaging usually adopts the fumigation well frame method, which is fixed with steel belts on the outside. The aluminum coil has a double-layer moisture-proof rain cloth on the outside, and the inside is protected from moisture-proof agents. It adopts sealed packaging, which is suitable for sea transportation.

- Q: What is the maximum width of aluminum coils?

- The maximum width of aluminum coils can vary depending on various factors such as the manufacturing process, the specific grade and type of aluminum, and the capabilities of the equipment being used. However, in general, aluminum coils can have a maximum width ranging from a few inches to several feet. Industrial coil lines can typically handle widths up to 72 inches, while specialized equipment may be able to accommodate even wider coils. It is important to consult with the manufacturer or supplier to determine the specific maximum width available for a particular application.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a popular choice for food storage containers due to its many beneficial properties. It is lightweight, durable, and has excellent thermal conductivity, meaning it can evenly distribute heat for efficient cooking or cooling. Additionally, aluminum is non-toxic, odorless, and resistant to corrosion, making it a safe option for storing food. It also provides an effective barrier against light, moisture, and oxygen, which helps to preserve the freshness and quality of the stored food. Overall, aluminum coils can be a reliable and practical choice for food storage containers.

- Q: Are aluminum coils prone to corrosion?

- Aluminum coils have a tendency to corrode, as aluminum is a reactive metal that readily develops a protective oxide layer upon contact with oxygen. Nevertheless, certain environmental elements like moisture, salt, or corrosive substances can compromise this oxide layer. Consequently, corrosion may gradually manifest on the surface of aluminum coils. To mitigate this risk, regular maintenance and appropriate care, such as cleaning and applying protective coatings, can be beneficial.

- Q: Can aluminum coils be used for thermal insulation purposes?

- No, aluminum coils cannot be used for thermal insulation purposes. Aluminum is a highly conductive metal, meaning it easily transfers heat. Therefore, using aluminum coils as thermal insulation would actually promote heat transfer rather than preventing it. For effective thermal insulation, materials with low thermal conductivity, such as fiberglass, foam, or mineral wool, are commonly used. These materials create a barrier that limits heat transfer, keeping the desired temperature within a space.

- Q: Can aluminum coils be utilized as a material for crafting jewelry?

- <p>Yes, aluminum coils can be used for making jewelry. Aluminum is a lightweight, durable, and affordable metal that is often used in costume jewelry and for decorative purposes. It can be easily shaped, bent, and manipulated into various forms, making it suitable for creating intricate designs. However, it's important to note that aluminum is a softer metal and may not be as durable as other metals like stainless steel or silver, so it may not be ideal for pieces that will be worn daily or subjected to significant wear and tear.</p>

- Q: How do aluminum coils contribute to sustainable manufacturing?

- Aluminum coils contribute to sustainable manufacturing by offering numerous environmental benefits. Firstly, aluminum is a highly recyclable material, meaning that the coils can be reused repeatedly without any degradation in quality. This reduces the need for virgin aluminum extraction, saving energy and resources. Additionally, the lightweight nature of aluminum coils reduces transportation costs and fuel consumption during shipping. Furthermore, aluminum is corrosion-resistant, leading to longer product lifespans and reducing the need for frequent replacements. Overall, the use of aluminum coils promotes sustainability through efficient resource utilization, reduced emissions, and increased product longevity.

- Q: Can aluminum coils be used in electrical busbars?

- Yes, aluminum coils can be used in electrical busbars. Aluminum is a commonly used material for busbars due to its high electrical conductivity, low cost, and lightweight properties. Aluminum coils can be easily formed into various shapes and sizes to fit specific busbar requirements. Additionally, aluminum has good thermal conductivity, which allows for efficient heat dissipation in high current applications. However, it is important to consider the current carrying capacity, mechanical strength, and corrosion resistance of aluminum coils when selecting them for busbar applications.

- Q: Can a spring balance be used to accurately determine the weight of an aluminum coil?

- <p>Yes, you can use a spring balance to measure the weight of an aluminum coil, but the accuracy depends on the balance's specifications. Ensure the balance has a sufficient capacity to measure the coil's weight and is calibrated correctly. Keep in mind that spring balances are less precise than electronic scales, especially for heavy or sensitive measurements. For high accuracy, consider using an electronic scale designed for industrial use.</p>

- Q: How do aluminum coils compare to other metal coils in terms of cost?

- Aluminum coils are generally more cost-effective compared to other metal coils due to the lower cost of aluminum as a raw material and its abundance in nature. Additionally, aluminum coils offer superior corrosion resistance, lightweight properties, and energy efficiency, making them a cost-efficient choice in various applications.

- Q: Is it possible to use a welding torch for joining steel coils?

- <p>Yes, you can use a welding torch to weld steel coils together. However, it's important to choose the right type of welding process suitable for the specific steel grade and the desired strength of the joint. Common methods include gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW). Ensure you follow safety protocols, use appropriate protective gear, and have a good understanding of the welding process to achieve strong, reliable welds.</p>

Send your message to us

Cold rolled aluminum coil 0.15-4.0mm 1060 1100 3003 3105 5052 Aluminum alloy coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords