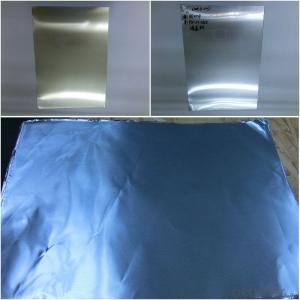

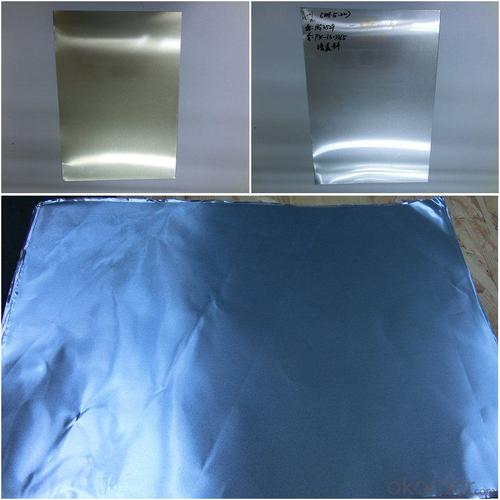

Aluminum Transparent Color Coated Foil and Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Foil for industrial air ducting system

1100H22

0.06mm*1215mm

Top side coating: light blue color epoxy coating

Back side coating: transparent water-base epoxy coating

PE Aluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

Raw Material of the PE Aluminum CoatingCoils:

1.Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy isavailable with AA3003, AA3005, AA5005 according to customer)

2.Surface Paint: PE, PVDF and special paints.

Specificationof PE Aluminum Coating Coil

Width:20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coilweight: ≤ 4000kg

PE coatedaluminum coil is processed through the technics of roller coating and bakingwith precise polyester paints. Its color is glossy and with variety of colorsenabling you to choose easily. Chromatic aberration is small, impact resistanceis strong and easy to be processed, and all its performance has reached orsurpassed the national criteria. The products are widely used in indoor anddoor decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performanceof the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Colorof Card

PE (polyester)

PE

ColorMatch

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: This question asks for methods to determine the presence of aluminum in an alloy.

- <p>To determine if an alloy contains aluminum, one can use various analytical techniques. A common method is spectroscopy, which can identify the presence of specific elements by analyzing the wavelengths of light absorbed or emitted. Another approach is the use of a spark test, where a sample is struck against a grinding wheel to produce sparks; the color and pattern of these sparks can indicate the presence of aluminum. Chemical tests, such as the reaction with sodium hydroxide, can also be used, as aluminum reacts with NaOH to produce hydrogen gas. Lastly, X-ray fluorescence (XRF) is a non-destructive technique that can accurately determine the elemental composition of an alloy, including aluminum content.</p>

- Q: Explain the impact of aluminum on manufacturing processes in a few sentences.

- <p>The use of aluminum significantly affects manufacturing processes by offering several advantages. It is lightweight, which reduces the weight of products and can lead to fuel efficiency in transportation sectors. Aluminum's high strength-to-weight ratio makes it ideal for structural components. Its excellent thermal and electrical conductivity allows for efficient heat dissipation and electrical transmission. Additionally, aluminum is non-magnetic and non-corrosive, which is beneficial for certain applications. The metal is also easily recyclable, contributing to sustainability in manufacturing. These properties make aluminum a popular choice in industries such as automotive, aerospace, construction, and electronics, enhancing the efficiency and performance of manufacturing processes.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional recycling process?

- <p>Yes, aluminum can be recycled in different ways. Apart from the conventional recycling process, which involves melting and recasting, there are innovative methods being explored. One such method is mechanical recycling, where aluminum is cleaned, sorted, and processed into new products without melting. Another approach is chemical recycling, which breaks down aluminum into its constituent elements and then reassembles them into new materials. These alternative methods aim to reduce energy consumption and environmental impact while still effectively recycling aluminum.</p>

- Q: Can the recycling of aluminum be done in a closed loop system without any degradation in the material's quality?

- <p>Yes, aluminum can be recycled using a closed loop process without losing quality. Aluminum is infinitely recyclable, meaning it can be recycled over and over again without losing its properties. The recycling process involves melting the aluminum, which is much less energy-intensive than the original production from raw materials. This closed-loop recycling system helps maintain the quality of aluminum, making it an environmentally friendly and sustainable material.</p>

- Q: Explain how the use of aluminum impacts energy consumption, including its production and recycling processes.

- <p>The use of aluminum has a significant impact on energy consumption, particularly in its production process. Aluminum is an energy-intensive material to produce, requiring large amounts of electricity to extract from its ore, bauxite, through a process called electrolysis. This process accounts for about 5% of global electricity consumption. However, aluminum is also highly recyclable, and recycling aluminum uses only 5% of the energy needed to produce it from raw materials. This makes aluminum recycling a more energy-efficient process, reducing the overall energy consumption related to aluminum use when recycling is prevalent.</p>

- Q: What are the differences between Aluminum Oxide and Aluminum Alloy in terms of their properties and applications?

- <p>Aluminum Oxide and Aluminum Alloy are distinct materials with different properties and uses. Aluminum Oxide, also known as alumina, is a ceramic material with a high melting point, hardness, and electrical insulation properties. It's used in abrasives, electronics, and as a refractory material. In contrast, Aluminum Alloys are composites of aluminum with other elements like copper, magnesium, or silicon, which enhance their strength, corrosion resistance, and malleability. They are widely used in construction, automotive, aerospace, and packaging due to their lightweight and durability.</p>

- Q: This question asks for a list of typical flaws or imperfections that can occur in aluminum products.

- <p>Common defects in aluminum products include porosity, which refers to small holes or voids within the material; surface defects such as scratches, dents, and discoloration; mechanical defects like warping or deformation; and metallurgical defects such as inclusions or impurities. Additionally, aluminum products can suffer from corrosion, which can lead to pitting or general surface degradation, and stress corrosion cracking, which occurs under certain environmental conditions and stress. Each of these defects can impact the structural integrity, appearance, or performance of aluminum products.</p>

- Q: This question asks for the specific temperature at which aluminum changes from a solid to a liquid state.

- <p>The melting point of aluminum is approximately 660.32 degrees Celsius (1220.58 degrees Fahrenheit). This is the temperature at which solid aluminum begins to melt and transform into a liquid state.</p>

- Q: This question asks whether the energy consumption for producing recycled aluminum is lower compared to the production of new aluminum.

- <p>Yes, producing recycled aluminum requires significantly less energy than producing new aluminum. Recycling aluminum uses only about 5% of the energy needed to produce primary aluminum from bauxite ore. This is because recycling involves melting and recasting the metal, which is a much less energy-intensive process than mining, refining, and smelting new aluminum. As a result, recycling aluminum helps conserve energy and reduces greenhouse gas emissions associated with aluminum production.</p>

- Q: This question asks for a comparison between aluminum and magnesium, two common metallic elements, highlighting their differences.

- <p>Aluminum and magnesium are both lightweight metals with distinct properties. Aluminum is more abundant in the Earth's crust and is known for its high strength-to-weight ratio, making it ideal for construction and transportation. It is also a good conductor of heat and electricity. Magnesium, while also lightweight, is less dense and has a lower melting point than aluminum. It is highly reactive and is often used in alloys to increase strength and durability. Magnesium is also essential for biological processes and is commonly found in supplements. In terms of reactivity, magnesium is more reactive than aluminum, which makes it more prone to corrosion in certain environments.</p>

Send your message to us

Aluminum Transparent Color Coated Foil and Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords