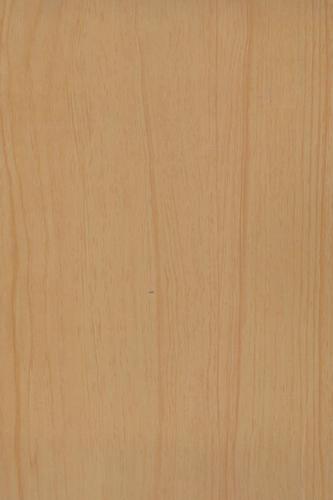

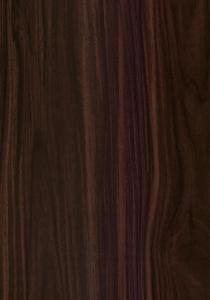

Aluminum Wood Grain Coating Coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: This question asks for a list of typical metal alloys that are utilized in the production of cars.

- <p>Common alloys used in automobile manufacturing include steel alloys such as low carbon steel, high-strength steel, and stainless steel for body and frame construction. Aluminum alloys are also widely used for their lightweight properties, especially in engine components and body panels. Magnesium alloys are employed for parts requiring high strength-to-weight ratios. Additionally, cast iron is used for engine blocks and cylinder heads, while copper alloys are utilized in radiators and electrical wiring. Titanium alloys find use in high-performance or luxury vehicles for their exceptional strength and low weight.</p>

- Q: Is there a new technology available for recycling aluminum?

- <p>Yes, new technologies are being developed and implemented for recycling aluminum more efficiently. One such technology is the use of advanced sorting systems that can separate different types of metals, including aluminum, from waste streams. Additionally, there are innovations in the smelting process that reduce energy consumption and emissions. For instance, some companies are using inert anodes in the electrolytic process to produce aluminum, which can significantly lower the carbon footprint. These advancements not only make aluminum recycling more environmentally friendly but also more economically viable.</p>

- Q: Is it possible to recycle old aluminum products and what are the benefits of doing so?

- <p>Yes, old aluminum products can be recycled. Recycling aluminum is highly beneficial as it conserves resources, saves energy, and reduces waste. The process of recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials, making it an environmentally friendly option. Additionally, recycling helps to decrease the amount of aluminum that ends up in landfills, thus reducing the environmental impact of mining and processing new aluminum.</p>

- Q: Is it possible to utilize recycled aluminum for the production of cars or other types of vehicles?

- <p>Yes, recycled aluminum can be used to make cars and other vehicles. It is common practice in the automotive industry to use recycled aluminum in the manufacturing process due to its lightweight and strong properties. Recycled aluminum requires less energy to produce than new aluminum, making it more sustainable. It is used in various parts of vehicles, including engine components, body panels, and wheels. The use of recycled aluminum not only reduces waste but also contributes to energy savings and carbon emission reductions in vehicle production.</p>

- Q: This question asks for various methods that can be used to recycle aluminum.

- <p>Recycling aluminum can be done through several methods, including mechanical recycling, which involves melting and reprocessing aluminum without altering its chemical properties. This is the most common method due to its efficiency and cost-effectiveness. Another method is chemical recycling, where aluminum is treated with chemicals to break it down into its constituent elements, which can then be repurposed. Additionally, aluminum can be recycled through a process called hydrometallurgical recycling, which uses aqueous solutions to extract aluminum from waste. Finally, sorting and collection play a crucial role in ensuring that aluminum waste is directed to appropriate recycling facilities where these methods can be applied.</p>

- Q: Explain the interaction between aluminum and oxygen.

- <p>Aluminum and oxygen have a reactive relationship. When aluminum is exposed to oxygen, it forms a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further oxidation of the aluminum beneath it, making aluminum a corrosion-resistant metal. The reaction is exothermic and can be represented by the chemical equation: 4Al + 3O2 鈫?2Al2O3. This aluminum oxide layer is hard and stable, which is why aluminum is widely used in various applications where resistance to corrosion is important.</p>

- Q: Is it possible to utilize aluminum in the construction of airplanes to enhance fuel efficiency?

- <p>Yes, using aluminum can make airplanes more fuel efficient. Aluminum is lightweight, which reduces the overall weight of the aircraft, leading to lower fuel consumption. Additionally, aluminum has good strength-to-weight ratio and is resistant to corrosion, making it a popular material in aircraft construction. However, it's important to note that the use of aluminum must be balanced with other materials to ensure structural integrity and safety.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: This question asks for the specific temperature at which aluminum changes from a solid to a liquid state.

- <p>The melting point of aluminum is approximately 660.32 degrees Celsius (1220.58 degrees Fahrenheit). This is the temperature at which solid aluminum begins to melt and transform into a liquid state.</p>

- Q: This question asks for examples of alloys that include aluminum as one of their components.

- <p>Aluminum is a versatile metal that forms many alloys, enhancing properties like strength, corrosion resistance, and electrical conductivity. Some common aluminum alloys include: 1. 6061, used in aircraft structures and automotive parts due to its good mechanical properties and machinability. 2. 2024, known as 'Alclad', is strong and used in aircraft structures. 3. 7075, one of the strongest aluminum alloys, used in aerospace and military applications. 4. 3003, used for cooking utensils and chemical equipment due to its good corrosion resistance. 5. 5052, used in marine applications and food processing equipment for its excellent corrosion resistance. These alloys are widely used in various industries due to their unique properties.</p>

Send your message to us

Aluminum Wood Grain Coating Coil

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords