024 Aluminum Coil - Red Coating Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Red Coating Aluminum Coil for Decoration

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Red Coating Aluminum Coil for Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Red Coating Aluminum Coil for Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

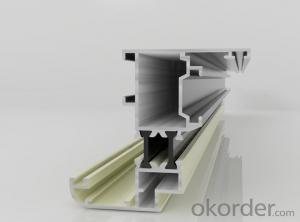

5. Image of Red Coating Aluminum Coil for Decoration

6. Package and shipping of Red Coating Aluminum Coil for Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the creep resistance of aluminum coils?

- The creep resistance of aluminum coils is generally high, as aluminum has a low melting point and exhibits minimal creep deformation under normal operating conditions.

- Q: What are the different tempers of aluminum coils?

- The different tempers of aluminum coils refer to the varying levels of hardness and strength that can be achieved through different heat treatments. Aluminum coils can be subjected to various tempering processes to alter their physical and mechanical properties for specific applications. The most common tempers for aluminum coils include: 1. Soft (O Temper): This temper represents the annealed state of aluminum, where the metal is fully soft and easily formable. It has low strength but excellent ductility, making it suitable for applications that require extensive shaping or bending. 2. Half Hard (H14 Temper): This temper offers moderate strength and hardness, while still retaining some formability. It is used in applications where a balance between strength and flexibility is necessary, such as roofing or cladding. 3. Hard (H18 Temper): This temper provides high strength and hardness, with reduced formability. It is commonly used in applications that demand structural integrity and resistance to deformation, such as automotive parts or industrial equipment. 4. Extra Hard (H22, H24, H26 Temper): These tempers are achieved through additional cold working or strain hardening processes. They offer even higher strength and hardness but sacrifice some ductility. They are often utilized in applications that require enhanced mechanical properties, such as aerospace components or high-stress structural parts. 5. Tension Leveled (T Temper): This temper involves stretching the aluminum coil beyond its elastic limit and then stabilizing it. It helps to eliminate internal stresses and improve flatness, making it suitable for applications that demand precise dimensional stability, like electronic devices or architectural panels. It is important to note that there are many other tempers available for aluminum coils, each designed to meet specific requirements. The choice of temper depends on factors such as the intended application, desired mechanical properties, and processing capabilities.

- Q: Can aluminum coils be used for cladding purposes?

- Certainly, cladding purposes can make use of aluminum coils. The lightweight quality, durability, corrosion resistance, and versatility of aluminum make it a popular choice for cladding. A wide variety of cladding systems, such as curtain walls, rain screens, and facade panels, can be created using aluminum coils. These coils are easy to form, cut, and install, making them a cost-effective and efficient solution for cladding. Moreover, the natural oxide layer of aluminum provides weathering protection and requires minimal maintenance. In conclusion, aluminum coils offer both aesthetic appeal and functional advantages, making them a suitable option for cladding purposes.

- Q: I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- What is your machine that you will be using? Can you weld AC on it? Do you have a High Freq. Box? Will you GTAW it or use GMAW? What Alloy of Aluminum is it? Need much more info than you have provided. If GMAW best to have a pull or a push / pull wire feed system such as in a spool gun. Aluminum is too soft to just push from a wire feeder unit.

- Q: What are the potential dangers associated with the use of aluminum coil?

- <p>Aluminum coil, when used in appropriate applications and handled correctly, is generally safe. However, there are some safety risks to consider: exposure to aluminum dust can cause respiratory issues, and improper handling can lead to cuts or burns. Additionally, aluminum can react with certain chemicals, potentially causing hazardous situations. It's important to use personal protective equipment and follow safety guidelines when working with aluminum coil to minimize these risks.</p>

- Q: Are aluminum coils suitable for gutter systems?

- Indeed, gutter systems find aluminum coils to be quite suitable. Given its durability, lightweight composition, and exceptional resistance to rust and corrosion, aluminum stands as a favored selection for gutter systems. This cost-effective alternative can endure severe weather conditions while boasting an extensive lifespan. Furthermore, the installation and maintenance of aluminum coils prove to be effortless, rendering them an optimal choice for gutter systems.

- Q: What are the differences among various types of steel wires and their respective coiling techniques?

- <p>Yes, there are differences between different types of steel wires and their coiling methods. Steel wires can be categorized based on their composition, strength, and use, such as carbon steel, stainless steel, and alloy steel wires. Each type has unique properties that affect their coiling methods. For instance, carbon steel wires are strong and ductile, suitable for standard coiling techniques, while stainless steel wires offer corrosion resistance and may require special handling to prevent damage. The coiling methods also vary; some common ones include spool coiling, loop coiling, and pancake coiling. Each method has specific applications and considerations for wire diameter, tension, and storage. Understanding these differences is crucial for selecting the appropriate wire and coiling technique for a given application.</p>

- Q: What are the different thickness tolerances for aluminum coils?

- The specific grade and application of aluminum coils can cause variations in their thickness tolerances. Generally, the standard range for these tolerances is typically between +/- 0.002 and 0.015 inches. Consequently, the actual thickness of the aluminum coil can differ within these limits. The specific tolerance requirements may also be affected by factors like the manufacturing process and the intended use of the coil. Therefore, it is crucial to refer to industry standards and specifications to ascertain the necessary thickness tolerances for a specific application.

- Q: Can aluminum coils be used for electrical enclosures?

- Yes, aluminum coils can be used for electrical enclosures. Aluminum is a commonly used material for enclosures due to its excellent conductivity, lightweight nature, and resistance to corrosion. It provides good protection against electromagnetic interference and can effectively dissipate heat. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, making them suitable for electrical enclosures in different applications.

- Q: How are aluminum coils used in rainwater harvesting systems?

- Aluminum coils are commonly used in rainwater harvesting systems for their durability and efficient heat transfer properties. These coils are typically installed within the rainwater storage tanks and are connected to a heat exchanger system. The primary function of the aluminum coils in rainwater harvesting systems is to facilitate the heating or cooling of the stored rainwater, depending on the intended use. For instance, if the harvested rainwater is intended for domestic use, such as for showers or laundry, the aluminum coils can help heat the water to a desired temperature. On the other hand, if the harvested rainwater is intended for cooling purposes, such as air conditioning or industrial processes, the coils can help cool the water as well. The aluminum coils are designed in a way that maximizes the surface area exposed to the rainwater, allowing for efficient heat transfer. This means that the coils can rapidly absorb or release heat, depending on the needs of the system. The aluminum material used for these coils is preferred due to its high thermal conductivity, corrosion resistance, and lightweight properties. Additionally, the coils are also beneficial in preventing the growth of bacteria and algae within the rainwater storage tanks. Aluminum has natural antimicrobial properties that inhibit the growth of these organisms and ensure the harvested rainwater remains clean and safe for use. Overall, aluminum coils play a crucial role in rainwater harvesting systems by enhancing the usability of the collected rainwater through efficient heat transfer and maintenance of water quality.

Send your message to us

024 Aluminum Coil - Red Coating Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords