Pre-Painted Galvanized/Aluzinc Steel Coil,Red Color of Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

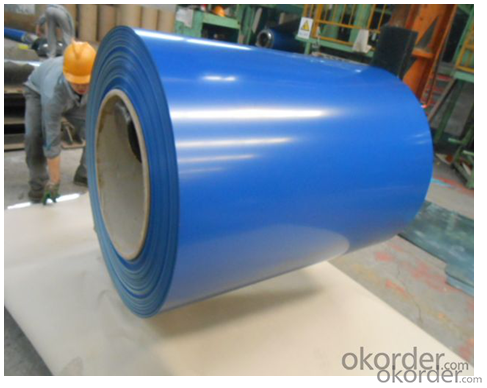

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel coil packaging machines?

- There are several different types of steel coil packaging machines available in the market. These machines are designed to efficiently and effectively package steel coils for storage, transportation, or distribution. Some of the different types of steel coil packaging machines include: 1. Automatic steel coil packaging machine: This type of machine is fully automated and can handle high-volume packaging requirements. It uses advanced technology to wrap the steel coils with a protective layer of film or paper. The machine can also apply strapping or stretch film to secure the coils during transportation. 2. Semi-automatic steel coil packaging machine: This machine requires some manual intervention to load and unload the steel coils. It is suitable for medium to high-volume packaging needs and offers a good balance between automation and cost-effectiveness. The machine typically uses a combination of wrapping, strapping, and shrinking techniques to package the coils. 3. Vertical steel coil packaging machine: This type of machine is designed specifically for packaging vertical steel coils. It can wrap the coils with a layer of film or paper, and then apply strapping or stretch film to secure them. The vertical design allows for easy loading and unloading of the coils. 4. Horizontal steel coil packaging machine: This machine is ideal for packaging horizontal steel coils. It can wrap the coils with a protective layer of film or paper, and then apply strapping or stretch film to secure them. The horizontal design ensures easy loading and unloading of the coils. 5. Customized steel coil packaging machine: Some manufacturers offer customized packaging solutions based on specific requirements. These machines can be tailored to accommodate different coil sizes, shapes, and packaging materials. They are designed to provide maximum flexibility and efficiency in the packaging process. In summary, the different types of steel coil packaging machines include automatic, semi-automatic, vertical, horizontal, and customized machines. The choice of machine depends on factors such as packaging volume, coil orientation, and specific requirements of the steel coils being packaged.

- Q: How is steel sustainable as a building material?How is wood sustainable as a building material?

- The choice is yours to make so just click on the proper button for the specific project and then they are right there for you to pick one. The diagrams and instructions will be right there in the computer for you to access at any time or if you prefer you can print them out.

- Q: How are steel coils used in the production of metal fixtures?

- Steel coils are an essential component in the production of metal fixtures. These coils, which are typically made from carbon steel, are used as the primary raw material to manufacture a wide range of metal fixtures. The steel coils are first uncoiled and then cut into sheets of the desired size and thickness. These sheets serve as the base material for different types of metal fixtures, including brackets, hinges, handles, and other structural components. Once the sheets are cut, they undergo various forming processes such as bending, stamping, or rolling. These processes help shape the steel sheets into the specific design required for the metal fixture. For instance, bending may be used to create brackets or angles, while stamping can be used to form intricate patterns or shapes. After the forming processes, the steel sheets are often subjected to welding or joining techniques to assemble multiple components of the metal fixture. Welding ensures that the various parts are securely attached, providing strength and durability to the final product. Furthermore, steel coils also play a crucial role in enhancing the appearance and longevity of metal fixtures. They can be coated or treated with protective layers, such as galvanized or powder coatings, to prevent corrosion and provide a polished finish. These coatings ensure that the metal fixtures can withstand environmental factors and extend their lifespan. In summary, steel coils are an integral part of the production process for metal fixtures. They are transformed into sheets, which are then shaped, joined, and coated to create a wide range of functional and aesthetically pleasing metal fixtures used in various industries.

- Q: How are steel coils unloaded from a truck?

- Steel coils are typically unloaded from a truck using specific equipment and a well-coordinated process. The unloading process involves several steps to ensure the safe and efficient removal of the steel coils. Firstly, a forklift or crane is typically used to reach inside the truck bed and secure the steel coil. The forklift or crane operator carefully positions the lifting apparatus underneath the coil, ensuring that it is centered and balanced. Once the steel coil is properly secured, the forklift or crane slowly lifts it out of the truck bed while maintaining stability. The operator must be cautious and consider factors such as the weight and dimensions of the coil to prevent any accidents or damage. After the steel coil is lifted out of the truck, it is usually placed onto a designated area such as a flatbed trailer, storage rack, or directly onto the ground. If placed on the ground, protective measures such as wooden blocks or rubber mats are often used to prevent any damage to the coil or the surface it is placed on. In some cases, steel coils may be unloaded using a specialized coil trailer, which is equipped with hydraulic systems to tilt the trailer bed and roll the coil off. This method is particularly useful for unloading larger and heavier coils. Overall, unloading steel coils from a truck requires skilled operators, appropriate lifting equipment, and adherence to safety protocols. It is essential to follow these steps meticulously to ensure the safe and efficient unloading of steel coils.

- Q: I noticed that Jimmy Page finger picked on a steel acoustic guitar on quite a few tracks like Stairway to heaven and other ones and I was wondering how did he do it? I know it is more difficult to finger pick on a steel acoustic because of the rougher steel strings and higher tensions so I was wondering do they make specific strings that allow for fingerstyle playing? Also Randy Rhoads finger picked a steel acoustic on Dee along with a Classical guitar.

- I've seen people put the guitar on a table and pick it that way. This is fairly common method in playing Bluegrass and country songs. There are finger picks that are used. These are finger rings with claws.

- Q: How does the surface finish of steel coils affect their performance?

- The surface finish of steel coils greatly affects their performance. A smooth and uniform surface finish enhances the coil's corrosion resistance, durability, and ability to resist wear and tear. It also improves the coil's ability to form and join with other materials, making it easier to work with during manufacturing processes. On the other hand, a rough or uneven surface finish can lead to decreased performance, as it can negatively impact the coil's ability to resist corrosion, reduce its overall strength, and potentially cause issues during processing and handling. Therefore, ensuring a proper surface finish is crucial in optimizing the performance and lifespan of steel coils.

- Q: I remember my dad saying something about steel toed boots but I forgot =#92; I went and checked out all the stores and got a pair with good ankle support but they also have steel toes. Would this interfere with the shifter or anything? I figure if anything my dirt bike shoes have the steel toes too. Any opinion?

- My work boots are steel caps i ride to work and home in them. I also wear them when I'm too lazy to change into my proper boots.I don't see any dramas with you wearing them they do come in handy for dogs that try to latch onto you. Ride safe.

- Q: I want an EDC (Every Day Carry) Knife that:~folds~is non-serrated~has a pocket clip~has a blade length of about 4 in. long~is concealable~urban environment friendly~priced around $50What do you suggest? I am currently thinking on purchasing the Cold Steel 4 inch Zytel Ti-Lite.

- Based okorder /

- Q: What type of metal is T10 tool steel?

- Carbon Tool Steel usually in the form of forged bar stock. Steel Grades for tool steel can be any of the following (depending on the application) T10/1.1645 SK3/SK4/W1A-91/2/ TC105/y10/1880/BW1B T10A/1.1545/y10A/1880 Standards are published by: DIN, JIS, ASTM, AISI, BS, SS, ISO, TOCT, GB Doug

- Q: What are the different grades of steel used for manufacturing coils?

- The different grades of steel used for manufacturing coils include low carbon steel, medium carbon steel, high carbon steel, and stainless steel.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil,Red Color of Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords