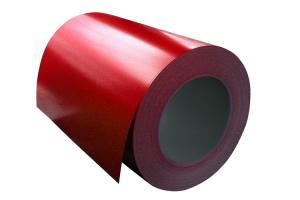

Pre-painted Galvanized Sheet Coil with Good Quality in Red

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

Pre-painted galvanized steel base metal,after pretreatment,degrease is good capable of decoration.

It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• good corrosion resistance

• perfect weather resistance

• Good visual effect

• High strength

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Thickness : 0.14-1.20 mm

Hardness of P: Both soft and hard quality are available

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Quality standar: JIS G3312 CGCC & CGLCC

Surface finish: with or without protect film

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

we will consider to give more discount if you make big order like 1000 tons and more.

- Q: What are the different coil packaging materials used for steel coils?

- Different materials are used for packaging steel coils, each with its own unique properties and benefits. Some of the most commonly used materials are as follows: 1. Stretch film is a flexible material that tightly wraps around the coil, providing protection against dust, moisture, and scratches. 2. Steel strapping is a strong and durable option that ensures the coils remain tightly bound during transportation or storage, thanks to its high tensile strength and resistance to breakage. 3. Plastic strapping, on the other hand, is a lightweight and cost-effective alternative to steel strapping. It offers good shock absorption and is resistant to rust and corrosion, making it suitable for smaller or lighter steel coils. 4. Paperboard is an environmentally friendly packaging material that provides a protective layer against dust and minor impacts. It also allows for slight breathability to prevent moisture buildup. 5. Wooden crates are commonly used for large or heavy steel coils, as they offer sturdy support and protection during handling, transportation, or storage. 6. Corrugated cardboard is a versatile and lightweight material suitable for smaller steel coils. It provides cushioning and protection against minor impacts, and it is easily recyclable. The choice of packaging material for steel coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. Each material has its own advantages and should be selected based on the specific needs of the steel coil packaging.

- Q: What are the common methods of packaging steel coils for international shipping?

- The common methods of packaging steel coils for international shipping include using wooden crates or pallets, securing the coils with metal or plastic strapping, using moisture-resistant packaging materials, such as plastic or shrink wrap, and adding dunnage or cushioning materials to prevent movement or damage during transit. Additionally, steel coils may be packed in containers or onto flat racks for optimal stability and protection.

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- The young man in the video is using a steel string guitar. Steel string guitars can be played fingerstyle or with a pick. Classical guitars use nylon strings and are only played fingerstyle. Classical guitars are used almost exclusively for playing classical music. If you're not interested in playing classical music then it's the wrong guitar for you. Steel string guitars can be used for a wide range of musical styles from pop to rock to folk to bluegrass to country, and more. Don't worry about pain - your fingers will hurt at first with either nylon or steel strings but that passes quickly. Buy the guitar that's most appropriate for the music you want to play.

- Q: How are steel coils used in the manufacturing of metal containers?

- Steel coils are used in the manufacturing of metal containers by being unrolled and shaped into the desired form using specialized machinery. These coils provide the necessary strength and durability to the containers, ensuring they can withstand the rigors of transportation and storage.

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- It is the Yield Strenght that you are looking for...that is another word for elastic limit. AND, for steel, it does depend on the variant of steel. Not all types of steel are identical, since steel isn't a pure substance. For Young's modulus (and other stiffness properties), just about all variants have the same values. However, for strength properties like Yield strength and ultimate strength and fatigue strength, it does depend on variant, and is precisely why different recipies exist in AISI standards.

- Q: What are the different types of welding methods used for steel coils?

- There are several different types of welding methods used for steel coils, including gas metal arc welding (GMAW), flux-cored arc welding (FCAW), shielded metal arc welding (SMAW), and submerged arc welding (SAW). Each method has its own advantages and is used based on the specific requirements of the project.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Stainless Steel Water Can

- Q: What type of metal is T10 tool steel?

- Carbon Tool Steel usually in the form of forged bar stock. Steel Grades for tool steel can be any of the following (depending on the application) T10/1.1645 SK3/SK4/W1A-91/2/ TC105/y10/1880/BW1B T10A/1.1545/y10A/1880 Standards are published by: DIN, JIS, ASTM, AISI, BS, SS, ISO, TOCT, GB Doug

- Q: What are the different methods of coil slitting for steel coils?

- There are several different methods of coil slitting for steel coils, each of which serves a specific purpose and is used in different industries. Here are some of the common methods: 1. Rotary shear slitting: This is the most widely used method for coil slitting. It involves using a set of rotating knives to cut the steel coil into smaller strips. The rotary shear slitting method is known for its high speed and accuracy, making it ideal for large-scale production. 2. Loop slitting: In this method, the steel coil is fed through a loop control system that maintains a constant tension. The coil is then cut into strips using a rotating knife. Loop slitting is commonly used for thinner gauge materials and is known for its ability to produce clean, burr-free edges. 3. Oscillating shear slitting: This method involves using a set of oscillating knives to cut the steel coil. The knives move back and forth in a rapid motion, creating a shearing effect that cuts through the coil. Oscillating shear slitting is often used for thicker gauge materials and can handle higher tensile strengths. 4. Crush cut slitting: Crush cut slitting is a method where the steel coil is cut by pressing a circular blade against the coil. The blade crushes the material, creating a cut. This method is commonly used for softer materials or when edge quality is not critical. 5. Slit edge rolling: Slit edge rolling is a method that involves rolling the edges of the steel coil after it has been slit. This process smooths out the edges and improves the overall appearance of the strips. Slit edge rolling is often used for applications that require a high-quality finish. 6. Laser slitting: Laser slitting is a newer method that uses a laser beam to cut through the steel coil. This method is precise and can handle a wide range of thicknesses. Laser slitting is commonly used for high-precision applications where edge quality is critical. These are just a few of the different methods of coil slitting for steel coils. The choice of method depends on factors such as the thickness and tensile strength of the material, the required edge quality, and the intended application of the slitted strips.

- Q: Moravia’s coal and steel industries face challenges because they _____. a.do not run efficientlyb.have run out of resourcesc.have a declining work forced.have not privatized

- do not run efficiently is the correct answer

Send your message to us

Pre-painted Galvanized Sheet Coil with Good Quality in Red

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords