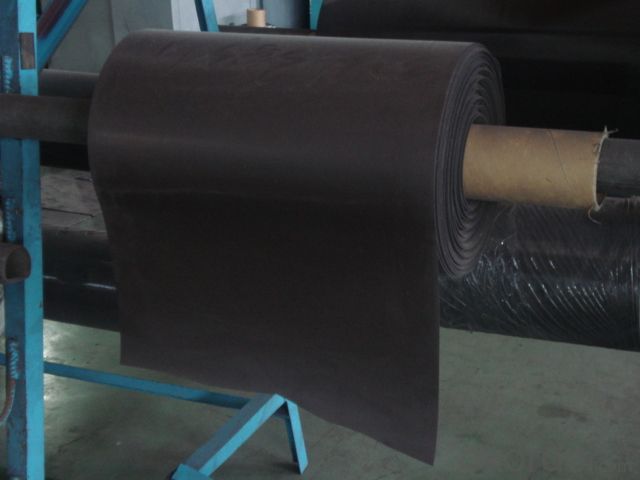

EPDM Waterproofing Membrane for Underlayment Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for EPDM Waterproofing Membrane:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic of EPDM Waterproofing Membrane:

1. the excellent anti-aging, in the long term light, humidity, cold use of the natural

environment, small changes in physical properties, used in the temperature:

From -50 degree Celsius to +80degree Celsious.

2.with outstanding ozone resistance, resistance to ultraviolet and atmospheric corrosion

of many chemical corrosive substances.

3. high tensile strength, high elongation, high flexibility, capable of sustaining

a puncture of hard material, good anti-crack, high adaptability of the grass roots'

contraction and the crack and deformation, and give full play to extend the

performance, playing the role of waterproofing.

4.long lifetime, high durability can achieve more than 25 years.

5.the cold construction operation, no environment pollution and simple operation.

Production Discription of EPDM Waterproofing Membrane:

EPDM waterproofing membrane is the modified materials. They are based upon EPDM rubber with modifier, softener and accelerant assistants added to provide flexibility and stability . Through the precise ingredients, mixing, extrusion, rolling, curing processes to made of modified EPDM Waterproofing material with high strength and high flexibility.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Yes, a waterproofing membrane can be used in government or municipal projects. In fact, it is a common practice to use waterproofing membranes in various infrastructure projects such as bridges, tunnels, parking structures, and government buildings. These membranes provide a reliable and durable solution to prevent water infiltration, protect the structural integrity of the project, and extend its lifespan. Additionally, waterproofing membranes can meet the necessary regulations and standards required for government or municipal projects.

- Q: Can a waterproofing membrane be used for modular buildings or container homes?

- Yes, a waterproofing membrane can be used for modular buildings or container homes. These structures often have unique challenges when it comes to waterproofing due to their modular construction and potential for water ingress at joints and connections. A waterproofing membrane can effectively seal these areas, preventing leaks and water damage. It can be applied to the exterior walls, roof, and foundation of the structure, providing a durable and long-lasting waterproof barrier. Additionally, a waterproofing membrane can be customized to meet the specific requirements of modular buildings and container homes, ensuring optimal protection against water infiltration.

- Q: Can waterproofing membranes be used on outdoor patios?

- Yes, waterproofing membranes can be used on outdoor patios. They are an effective way to protect the patio from water damage and can help to prevent leaks and moisture penetration. Waterproofing membranes create a barrier between the patio surface and water, keeping it dry and extending its lifespan.

- Q: Are waterproofing membranes suitable for rooftop gardens?

- Rooftop gardens require proper waterproofing to prevent water leakage and structural damage. Waterproofing membranes, made of materials like rubber, PVC, or modified bitumen, create a barrier to stop water from entering the building. These membranes are highly resistant to water penetration. Without reliable waterproofing, excess water from irrigation or rainfall can damage the building, fostering mold growth and deterioration. Waterproofing membranes effectively seal the rooftop, preventing water infiltration and providing a long-lasting solution. Moreover, waterproofing membranes offer additional benefits. They protect against root penetration, safeguarding the roof structure. They also regulate building temperature by reducing heat absorption, enhancing energy efficiency. It's crucial to hire professionals with expertise in waterproofing systems for membrane selection and installation. They ensure proper installation, defect-free membranes, and integration with other roofing components. In conclusion, waterproofing membranes are suitable for rooftop gardens. They protect against water ingress, root penetration, and structural damage, allowing rooftop gardens to thrive while maintaining the building's integrity and longevity.

- Q: What is the recommended temperature range for applying a waterproofing membrane?

- The recommended temperature range for applying a waterproofing membrane is typically between 40°F (4°C) and 90°F (32°C).

- Q: Can a waterproofing membrane be used for planter boxes or green roofs?

- Yes, a waterproofing membrane can be used for planter boxes or green roofs. In fact, it is highly recommended to use a waterproofing membrane in these cases to prevent water leakage and damage to the underlying structure. A waterproofing membrane acts as a protective barrier, preventing water from seeping into the planter boxes or green roofs and causing potential issues such as rot, mold, or structural damage. By effectively sealing the area, a waterproofing membrane ensures that the water is contained within the intended space, promoting healthy plant growth and preserving the integrity of the structure.

- Q: Can a waterproofing membrane be used on swimming pools?

- Indeed, swimming pools can utilize a waterproofing membrane. It is a prevalent and efficient technique to guarantee the pool's impermeability. Normally composed of PVC or rubber, waterproofing membranes are specially crafted to obstruct water infiltration through the pool's walls or floor. They are applied as a fine layer or sheet across the pool's surfaces, forming a barrier that confines the water within. This approach diminishes the likelihood of leaks and water-related harm, safeguarding the longevity and functionality of the pool.

- Q: What is the resistance type SBS waterproofing membrane?

- The second is chemical resistance, in the waterproofing membrane production process, adding chemical resistance agent, similar to the chemical composition of herbicides, the plant roots are not close to the waterproofing membrane; In addition, copper ions have a similar effect.

- Q: How long does it take for a waterproofing membrane to cure or dry?

- The time it takes for a waterproofing membrane to cure or dry can vary depending on various factors such as the specific product used, environmental conditions, and application method. However, on average, it usually takes around 24 to 48 hours for a waterproofing membrane to fully cure and dry. It is important to follow the manufacturer's instructions and allow sufficient time for the membrane to properly cure before subjecting it to water or other elements.

- Q: How does a waterproofing membrane handle expansion and contraction of the substrate?

- A waterproofing membrane is designed to accommodate the expansion and contraction of the substrate through its flexibility and elasticity. It can stretch and contract along with the movement of the substrate, ensuring a watertight seal is maintained without compromising its integrity.

Send your message to us

EPDM Waterproofing Membrane for Underlayment Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords