EPDM Waterproofing Membrane for Roofing Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product instruction

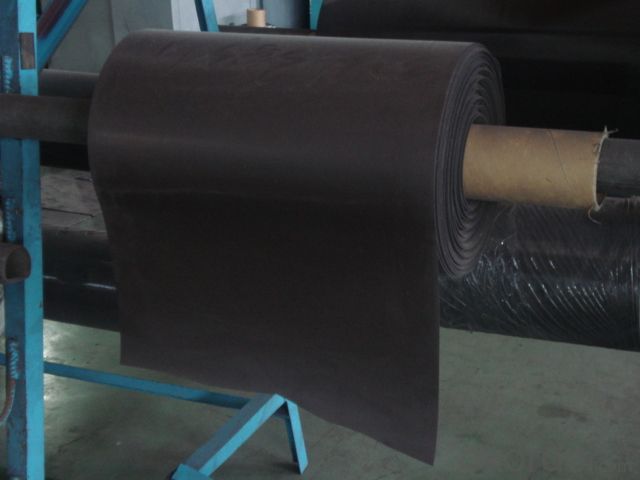

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Detailed Product Description

Product Name: High Polymer Waterproof Membrane

Width of roll: 1m; Thickness : 0.5mm , 1mm , 1.5mm,

Area of roll : 15sq.m , 10sq.m , 7.5sq.m;

Low temperature flexibility : -18/-25

Surfaced materials : PE film , granule, slate , metal foil , sand , mineral and etc;

Applications: Bridge building, storage, road, tunnel, parking station, swimming pool, water-disposal pool, rubbish-disposal places and other waterproofing project, especially for,easy broken structural and cold building protective;

Features

1) Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Application

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Introduction for EPDM Waterproofing Membrane:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Does a waterproofing membrane require any specific cleaning or maintenance procedures?

- To ensure the longevity and effectiveness of a waterproofing membrane, it is necessary to follow specific cleaning and maintenance procedures. Regular cleaning and maintenance are important to prevent the accumulation of debris, dirt, and contaminants that could compromise the membrane's ability to keep water out. The exact procedures for cleaning and maintenance may vary depending on the type of waterproofing membrane used, but there are some general guidelines to follow. Firstly, it is crucial to frequently inspect the membrane for any signs of damage, such as cracks, tears, or deterioration. If any issues are found, they should be addressed promptly to prevent further damage. When it comes to cleaning, it is recommended to use a soft-bristle broom or a leaf blower to remove loose debris or dirt from the membrane surface. It is important to avoid harsh chemicals or abrasive materials that could harm the membrane. Instead, a mild detergent or specialized cleaning solution recommended by the manufacturer should be used. The surface can be gently scrubbed with a soft brush or sponge and thoroughly rinsed with clean water. Additionally, it is vital to keep the surrounding drainage systems clear and free from obstructions. Regular inspection and cleaning of gutters, downspouts, and drains are necessary to ensure proper water flow and prevent potential water damage. Lastly, it is advisable to have the waterproofing membrane professionally inspected and maintained on a regular basis. This will help identify any potential issues early on and ensure that the membrane is functioning optimally. By following these specific cleaning and maintenance procedures, the lifespan of the waterproofing membrane can be prolonged, and its effectiveness in preventing water infiltration can be maintained.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic activity can cause significant ground movement and structural vibrations, which can potentially compromise the integrity of the membrane. Therefore, it is crucial to select a membrane that is specifically designed and tested to withstand seismic conditions. Additionally, proper installation techniques and materials, such as reinforced membranes and flexible adhesives, should be used to ensure the membrane remains intact during seismic events.

- Q: Can waterproofing membranes be used on plant rooms?

- Indeed, plant rooms can benefit from the utilization of waterproofing membranes. Within these rooms, one can typically find various apparatus and machinery that necessitate safeguarding against potential water harm. By implementing waterproofing membranes, a formidable defense is established to impede water infiltration, averting leaks and potential destruction to both the plant room and its contents. Typically, these membranes are administered to the walls, floors, and roofs of the plant room to ensure comprehensive waterproofing. Moreover, in addition to their water resistance, these membranes possess the ability to shield against other elements such as chemicals and fluctuations in temperature, rendering them an optimal solution for plant rooms.

- Q: Can a waterproofing membrane be used for planter boxes?

- Indeed, planter boxes can benefit from the utilization of a waterproofing membrane. The main purpose of a waterproofing membrane is to obstruct the passage of water through various surfaces, making it an effective remedy for safeguarding the planter box and its surroundings against water damage. When a waterproofing membrane is installed internally within the planter box, it establishes a protective barrier that prevents water from infiltrating the underlying materials, such as wood or concrete, thus prolonging the lifespan of the planter box. Furthermore, the presence of a waterproofing membrane can also assist in retaining moisture within the planter box, which proves advantageous for the plants thriving inside. Nonetheless, it is crucial to exercise caution when selecting a waterproofing membrane, ensuring that it is specifically tailored for planter boxes and poses no harm to the plants, thereby guaranteeing optimal outcomes.

- Q: Can a waterproofing membrane be used for balconies or decks?

- Yes, a waterproofing membrane can be used for balconies or decks. It is a common solution to prevent water damage and ensure the longevity of these outdoor structures.

- Q: What is the cost of installing a waterproofing membrane?

- The cost of installing a waterproofing membrane can vary depending on various factors such as the size of the area to be waterproofed, the type of membrane being used, and the complexity of the installation process. On average, the cost can range from $3 to $10 per square foot. However, it is important to note that this is just a rough estimate and the actual cost can be higher or lower depending on the specific requirements of the project. It is recommended to consult with a professional waterproofing contractor to get an accurate cost estimate tailored to your specific needs.

- Q: How does a waterproofing membrane handle extreme temperature fluctuations?

- A waterproofing membrane is designed to handle extreme temperature fluctuations by being resistant to temperature changes. It is typically made from materials that have a high tolerance for both hot and cold temperatures. These materials are chosen for their ability to expand and contract without losing their integrity or effectiveness. During hot weather, the waterproofing membrane will expand slightly to accommodate the increase in temperature. This expansion helps to prevent any cracks or gaps from forming that could allow water to penetrate the membrane. Similarly, during cold weather, the membrane will contract to avoid any damage caused by freezing temperatures. The ability of a waterproofing membrane to handle extreme temperature fluctuations is also achieved through its installation process. The membrane is typically applied in multiple layers, creating a seamless and flexible barrier. This layered application allows the membrane to withstand the stresses caused by temperature changes without compromising its protective properties. Additionally, some waterproofing membranes are equipped with special additives or reinforcements that enhance their ability to handle extreme temperature fluctuations. These additives can provide additional strength and flexibility, ensuring that the membrane remains intact and functional even in the face of severe temperature changes. Overall, a properly installed and maintained waterproofing membrane is designed to handle extreme temperature fluctuations by expanding and contracting, maintaining its integrity, and providing a consistent barrier against water intrusion.

- Q: Can a waterproofing membrane be used for below-grade parking garages?

- Yes, a waterproofing membrane can be used for below-grade parking garages. Waterproofing membranes are commonly used in construction projects to prevent the ingress of water into the structure. In below-grade parking garages, where the structure is below ground level, the risk of water infiltration is higher. Therefore, using a waterproofing membrane is an effective solution to protect the parking garage from water damage and ensure its durability.

- Q: Can a waterproofing membrane be used on precast brick block surfaces?

- Precast brick block surfaces can indeed benefit from the application of a waterproofing membrane. Such a membrane serves as a protective shield, safeguarding the bricks against water infiltration, which could otherwise lead to undesirable consequences like cracks, efflorescence, or the growth of mold. It is crucial to select a waterproofing membrane explicitly designed for masonry surfaces, as these membranes are specially formulated to adhere perfectly to the distinct properties of brick and block materials. Moreover, to guarantee the membrane's effectiveness, it is essential to adhere to proper surface preparation and application techniques.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Indeed, water treatment plants can benefit from the utilization of waterproofing membranes. These specialized membranes are specifically engineered to impede the flow of water, making them an ideal solution for safeguarding against water seepage in diverse structures, including water treatment plants. By applying these membranes to various sections of the facility, such as tanks, reservoirs, pipes, and basements, infiltration of water can be effectively prevented, thus shielding the infrastructure from potential harm. Furthermore, the implementation of waterproofing membranes aids in preserving the integrity of the water treatment process by ensuring that water remains confined within designated areas and does not permeate the surrounding soil or structures.

Send your message to us

EPDM Waterproofing Membrane for Roofing Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords