EPDM Rubber Waterproof Membrane for Thickness1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. What's the Product ?

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-

popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene

rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof

membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization

technology.

2. Features for EPDM Waterproof Membrane

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

3. Application for EPDM Waterproof Membrane

l Roofs, Basement, Toilet

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suit for projects with high requirements in durability, anti-corrosion and deformation

4 Specification for for EPDM Waterproof Membrane

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

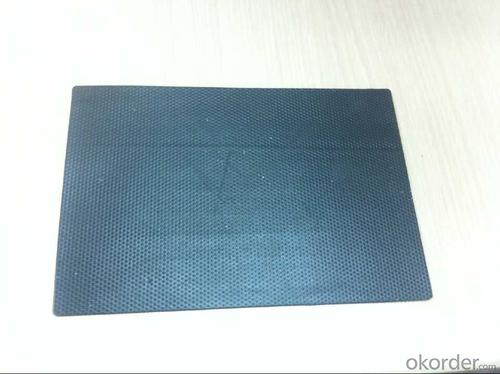

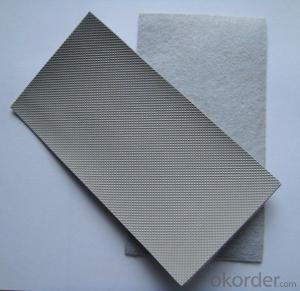

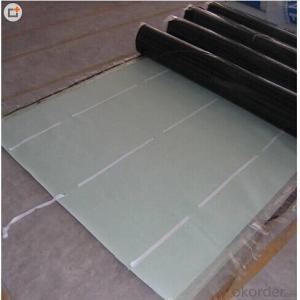

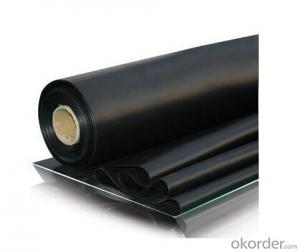

5. Image for EPDM Waterproof Membrane

5. Installations:

1. Adhere the EPDM membrane directly to the smooth and clean substrate like concrete deck, insulation board, etc.

2. Adjust membrane to make sure the overlaps is no less than 10cm and wiped clean.

3. Then, apply special adhesive evenly to both the substrate and the membrane laps or seam tape.

4. After minutes, press it securely and finish with sealant.

6. FAQ

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane,

Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane,

Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2.What's the main type for EPDM ?

Vulcanized and weldable are the main type .

3.What's the thickness for EPDM ?

1.2mm ,1.5mm ,2.0mm.

- Q: Is a waterproofing membrane resistant to gasoline or other petroleum-based substances?

- Yes, a waterproofing membrane is generally resistant to gasoline and other petroleum-based substances.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Indeed, precast insulation surfaces can make use of a waterproofing membrane. The primary purpose of this membrane is to create a safeguard against water infiltration, and it can be applied to diverse surfaces, such as precast insulation. In effect, the membrane serves to thwart water from penetrating the insulation, thereby averting potential harm and preserving its efficacy. By employing a waterproofing membrane on precast insulation surfaces, one can guarantee that the insulation stays dry and preserves its thermal properties for the long term.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Theaters and concert halls can benefit greatly from the use of waterproofing membranes. These membranes are commonly employed in construction projects to safeguard buildings against water damage by preventing water infiltration. They are applied to various surfaces, including walls, floors, and roofs, creating a barrier that stops water from seeping through. In the case of theaters and concert halls, where the protection of the building structure and equipment is of utmost importance, waterproofing membranes can be extremely advantageous. They play a crucial role in preventing water damage to delicate equipment like audiovisual systems, lighting fixtures, and musical instruments. Furthermore, these membranes ensure a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. In conclusion, the use of a waterproofing membrane in theaters or concert halls guarantees the longevity and functionality of the building, creating a safe and enjoyable experience for all involved.

- Q: Can waterproofing membranes be used on outdoor fountains?

- Yes, waterproofing membranes can be used on outdoor fountains. Waterproofing membranes are designed to create a barrier that prevents water from penetrating through surfaces, making them ideal for protecting outdoor fountains from water damage. These membranes are typically made of materials such as rubber, PVC, or bitumen, which are highly resistant to water and can effectively seal the fountain's structure. Applying a waterproofing membrane to an outdoor fountain can help prolong its lifespan, prevent leaks, and protect it from the elements.

- Q: Can a waterproofing membrane be used for tunnels?

- Yes, a waterproofing membrane can be used for tunnels. Tunnels are often exposed to water infiltration due to their underground nature, making waterproofing crucial to prevent water damage and ensure structural integrity. Waterproofing membranes, which are specially designed to provide a barrier against water penetration, can be applied to the tunnel walls, floors, and ceilings to create a waterproof seal. These membranes are typically made of materials such as bitumen, EPDM, PVC, or polyurethane, which are highly resistant to water and can withstand the constant exposure to moisture in tunnels. Additionally, waterproofing membranes can also provide protection against other potential sources of water ingress, such as groundwater or heavy rainfall. Overall, the use of a waterproofing membrane in tunnels is a reliable and effective method to maintain a dry and safe environment within the tunnel structure.

- Q: Can a waterproofing membrane be used for underground parking structures?

- Yes, a waterproofing membrane can be used for underground parking structures. Underground parking structures are particularly vulnerable to water infiltration due to their location and exposure to groundwater. Waterproofing membranes are designed to provide a protective barrier against water penetration, preventing potential damage to the structure and its contents. These membranes are typically applied to the exterior walls and floors of the underground parking structure, ensuring a watertight seal. Additionally, the use of a waterproofing membrane can also help to prevent the formation of moisture-related issues such as mold growth, corrosion, and deterioration of concrete. Therefore, incorporating a waterproofing membrane is essential for the long-term durability and functionality of underground parking structures.

- Q: Can waterproofing membranes be used on utility vaults?

- Utility vaults, which are commonly found underground and contain vital utility equipment like electrical transformers, water meters, and communication systems, can benefit from the use of waterproofing membranes. These structures are vulnerable to water infiltration, which can harm the equipment and disrupt its operation. To prevent water from entering utility vaults, waterproofing membranes are often employed. These membranes, typically composed of robust materials like rubber, PVC, or modified bitumen, form an impenetrable barrier against moisture. Applied to the walls and floors of the vault, they establish a tight seal that wards off any water seepage. By employing waterproofing membranes on utility vaults, the risk of water damage is significantly diminished. This safeguard ensures that the equipment housed within remains functional and undamaged for an extended period. Additionally, these membranes offer protection against other potential issues, such as leaks, corrosion, and chemical damage. However, it is crucial to note that the proper preparation of the surface and correct installation techniques are essential for a successful and enduring waterproofing system on utility vaults. Therefore, it is advisable to consult a professional waterproofing contractor with experience in working on utility vaults to achieve optimal results.

- Q: Can a waterproofing membrane be applied to existing structures?

- Yes, a waterproofing membrane can be applied to existing structures. The membrane acts as a protective barrier, preventing water from penetrating the structure and causing damage. It can be applied to various surfaces such as roofs, basements, and foundations, providing an effective solution for waterproofing existing buildings.

- Q: Can a waterproofing membrane be used in tunnels or underground structures?

- Absolutely, tunnels or underground structures can definitely benefit from the utilization of a waterproofing membrane. In fact, it is highly advisable to employ a waterproofing membrane in such environments to prevent any water-related harm or leakage. Due to their positioning and exposure to underground water sources, tunnels and underground structures are particularly susceptible to water infiltration. By acting as a protective barrier, the waterproofing membrane effectively prevents water from seeping into the tunnels or structures, thus averting potential structural damage or compromising the safety of the area. Its ability to establish a watertight seal ensures that the interior remains dry and devoid of any water-related problems such as mold growth, material corrosion, or degradation. Moreover, waterproofing membranes are specifically engineered to withstand the unique challenges posed by underground environments, including high water pressure, ground movement, and exposure to harsh chemicals. Hence, employing a waterproofing membrane is not only feasible but also indispensable for preserving the durability and integrity of tunnels and underground structures.

- Q: Is a waterproofing membrane resistant to UV radiation?

- Yes, a waterproofing membrane is typically resistant to UV radiation. Most waterproofing membranes are designed to be durable and long-lasting, and part of that includes being able to withstand exposure to UV rays. UV radiation from the sun can cause degradation and damage to various materials over time, including waterproofing membranes. However, manufacturers often incorporate UV stabilizers and additives into the membrane's composition to enhance its resistance to UV radiation. These additives help to prevent the breakdown of the membrane's structure, ensuring that it remains effective in preventing water infiltration and maintaining its overall performance for an extended period, even when exposed to direct sunlight. Additionally, some waterproofing membranes may have a protective layer or coating that offers additional UV resistance. It is always recommended to consult the manufacturer's specifications and guidelines to understand the specific UV resistance capabilities of a particular waterproofing membrane.

Send your message to us

EPDM Rubber Waterproof Membrane for Thickness1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords