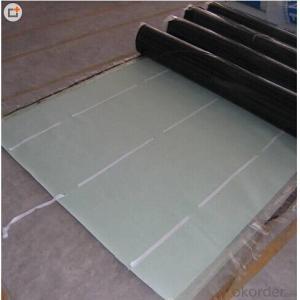

EPDM High Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A high polymer membrane is a type of synthetic sheet material made from high-performance polymers, such as PVC (polyvinyl chloride), TPO (thermoplastic polyolefin), or EPDM (ethylene propylene diene monomer). These membranes are known for their flexibility, durability, and excellent waterproofing properties, making them widely used in construction and industrial applications.

Description:

1.EPDM Waterproof Membrane / Roofing Material / Sheets Roofing

2.High tensile strength.

3.Good elongation.

4.UV resistant.

5.Anti-corrosion.

Main features:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6.Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low.

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. Start application till it is dry.

2. Reinforce the parts which are easy to leak, such as seam, hole, channel, wall, pipe and corner.

3. Application Method: Lay the membrane directly. Be careful to control the overlaps of the long side and short side.

4. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

FAQ:

Q:Can we get some samples before place order?

A:We can send the free samples to you by freight collect.

Q:How many years can your PVC membrane guarantee?

A:We will guarantee the quality for 5 years at least.

Q:Which countries you ever export the product?

A:We export the PVC membrane to South Africa, Middle east and even European countries.

Images:

- Q: Can a waterproofing membrane be used for concrete tank linings?

- Concrete tank linings can make use of waterproofing membranes, which are frequently employed in construction to obstruct water penetration and offer a protective shield. By applying a waterproofing membrane to the inner surfaces of a concrete tank, the infiltration of water and subsequent harm can be effectively averted. This becomes especially crucial for tanks that store fluids or chemicals, as any leakage can result in contamination or structural decay. By utilizing a waterproofing membrane, the tank can be shielded against water ingress, guaranteeing its durability and preserving its structural soundness.

- Q: Are waterproofing membranes suitable for high-traffic areas?

- Waterproofing membranes prove to be an ideal solution for areas with high foot traffic. Their purpose is to create a barrier against water infiltration, safeguarding the structure and preventing water-related harm. It is worth noting that high-traffic zones like walkways, driveways, parking lots, and other heavily frequented spaces are at risk of continuous exposure to water, resulting in structural damage and gradual deterioration. By employing waterproofing membranes in these areas, water penetration is effectively thwarted, guaranteeing their resilience and longevity. Furthermore, these membranes are often engineered to be slip-resistant, adding an extra layer of safety in high-traffic zones. Consequently, implementing waterproofing membranes in such areas is a prudent decision to address water-related concerns, preserve the structural integrity of the space, and ensure the safety of its occupants.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Certainly! Waterproofing membranes can be applied to tunnels that have emergency exits. It is strongly advised to utilize a waterproofing membrane in these tunnels to prevent water infiltration and safeguard the integrity of the exits. These membranes are specifically designed to establish a barrier against water and moisture, guaranteeing that the tunnels stay dry and unharmed by water. This is particularly crucial for emergency exits, as they must remain accessible and operational under all circumstances. By installing a waterproofing membrane, the tunnels can be adequately shielded from potential water ingress, thus ensuring the safety and functionality of the emergency exits.

- Q: Can a waterproofing membrane be used for tunnels and underground structures?

- Yes, a waterproofing membrane can definitely be used for tunnels and underground structures. These membranes are specifically designed to provide a protective barrier against water infiltration, preventing moisture from penetrating the structure and causing damage. They are highly effective in ensuring the long-term durability and structural integrity of tunnels and underground constructions.

- Q: Can a waterproofing membrane be used for plant rooms?

- Yes, a waterproofing membrane can be used for plant rooms. Plant rooms often house machinery and equipment that require protection from water and moisture. Using a waterproofing membrane can help prevent water damage to the plant room and the equipment inside. It creates a protective barrier that keeps water from penetrating the walls, floors, and ceilings of the plant room. This can be especially important in areas where there is a higher risk of water leaks or condensation. Waterproofing membranes are designed to withstand various environmental conditions and can provide long-lasting protection for plant rooms.

- Q: Can a waterproofing membrane be used in renovation or retrofitting projects?

- Certainly, a waterproofing membrane is a viable option for use in renovation or retrofitting endeavors. In fact, it often plays a crucial role in these projects, guaranteeing the long-term resilience and safeguarding of the building or structure. Waterproofing membranes are specifically designed to establish a barrier against moisture infiltration, effectively thwarting water damage, mold proliferation, and structural decay. When engaging in renovation or retrofitting tasks, it is not uncommon to encounter predicaments such as leaks, cracks, or deteriorated building materials that undermine the building's waterproofing system. In such scenarios, the application of a waterproofing membrane over the affected areas proves to be a reliable method of sealing and protecting them from further harm. This can be accomplished both internally and externally, tailored to the specific requirements at hand. Waterproofing membranes are available in a variety of forms, including sheet membranes, liquid coatings, or spray-applied membranes. They can be employed on various surfaces such as roofs, walls, basements, and even foundations. These membranes possess qualities such as flexibility, durability, and resistance to water and other environmental pressures, rendering them exceptional for renovation or retrofitting undertakings where augmenting the building's waterproofing capabilities is imperative. In conclusion, it is highly advisable to incorporate a waterproofing membrane into renovation or retrofitting ventures to ensure the endurance and integrity of the building. It serves as a proactive measure to preclude future water damage, preserve structural stability, and enhance the overall quality of the revitalized or retrofitted space.

- Q: Can a waterproofing membrane be used on green roofs?

- Yes, a waterproofing membrane can be used on green roofs. It is an essential component of the green roof system as it prevents water from penetrating the roof structure and causing damage. The waterproofing membrane ensures that the roof remains watertight and protects the building below from potential leaks.

- Q: Is a waterproofing membrane resistant to saltwater or salt damage?

- Yes, a waterproofing membrane is typically resistant to saltwater or salt damage. Waterproofing membranes are designed to provide a barrier against water and moisture, and they are commonly used in various applications where exposure to saltwater or salt is expected, such as in marine environments or near coastal areas. These membranes are often made from materials that are specifically formulated to withstand the corrosive effects of saltwater or salt. Additionally, the installation of a waterproofing membrane includes proper preparation and sealing techniques to ensure its resistance to saltwater or salt damage. However, it is important to note that the specific resistance of a waterproofing membrane to saltwater or salt damage may vary depending on the type and quality of the membrane used. Therefore, it is recommended to consult with a professional or manufacturer to ensure the appropriate membrane is selected for the specific application and environment.

- Q: Are waterproofing membranes environmentally friendly?

- Depending on the type and installation, waterproofing membranes have the potential to be environmentally friendly. Some membranes are manufactured with recycled materials, which reduces the need for new resources and waste generation. Moreover, certain membranes are designed for durability and longevity, reducing the frequency of replacement and overall environmental impact. Nevertheless, it is crucial to consider the potential adverse environmental effects of waterproofing membranes. Some membranes are composed of synthetic materials that may release harmful chemicals into the environment during production or degradation. Furthermore, improper installation or disposal of these membranes can result in pollution and contamination of soil and water sources. To ensure the environmental friendliness of waterproofing membranes, it is essential to select products certified as sustainable or eco-friendly by reputable organizations. Additionally, hiring experienced professionals for correct installation minimizes the risk of leaks or damage that could lead to environmental issues. Lastly, proper disposal of old or damaged membranes is vital to prevent pollution and ensure responsible waste management. In conclusion, waterproofing membranes can be environmentally friendly if appropriate materials are chosen, installation is performed correctly, and disposal is handled responsibly. It is crucial to assess the environmental impact of these membranes and make informed choices to minimize any negative effects.

- Q: Can a waterproofing membrane be used for historical buildings?

- Yes, a waterproofing membrane can be used for historical buildings. While it is important to preserve the architectural integrity and historical value of such buildings, it is equally essential to protect them from water damage. Waterproofing membranes provide an effective solution to prevent water infiltration and subsequent decay or deterioration. These membranes can be applied to various surfaces, including roofs, walls, and foundations, without compromising the aesthetics of the historical structure. It is crucial to choose a waterproofing membrane that is suitable for historical buildings, considering factors such as breathability, compatibility with the existing materials, and adherence to preservation guidelines. By using a carefully selected and properly installed waterproofing membrane, historical buildings can be protected from moisture-related issues, ensuring their longevity and continued preservation.

Send your message to us

EPDM High Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords