TPO/PVC High Polymer Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Thermoplastic Polyolefin (TPO) Waterproof Membrane

Product Introduction

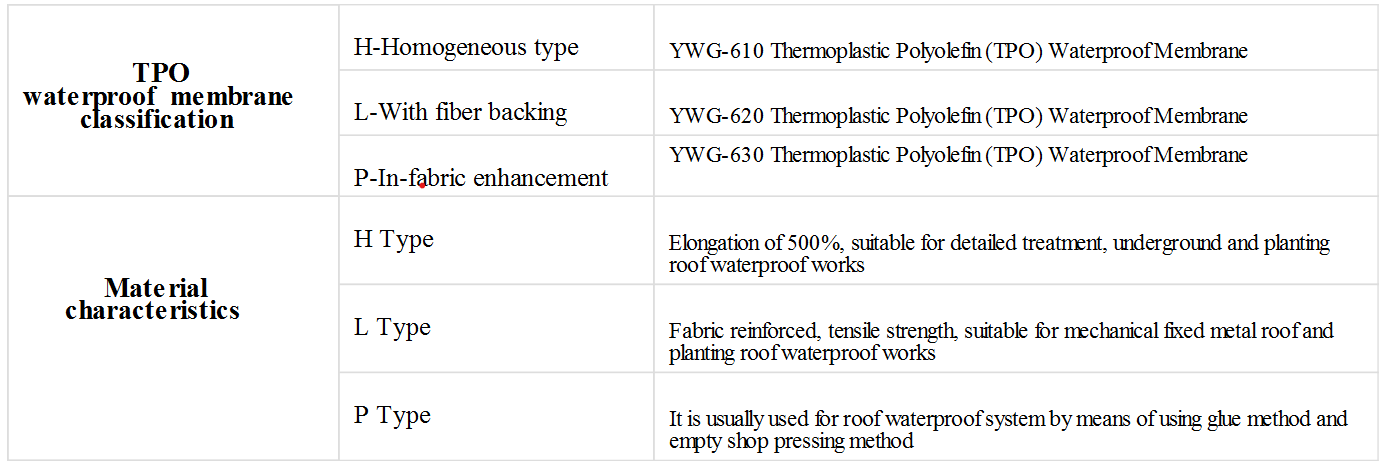

The product is made of thermoplastic polyolefin synthetic resin (TPO) as the base material and adopts advanced processing technology to make flake polymer waterproof material. TPO membrane is made of EPDM rubber for weathering and aging resistance and polypropylene for weld ability. In addition, it has the advantages of chemical corrosion resistance, high and low temperature resistance, and good dimensional stability.

Product Classification

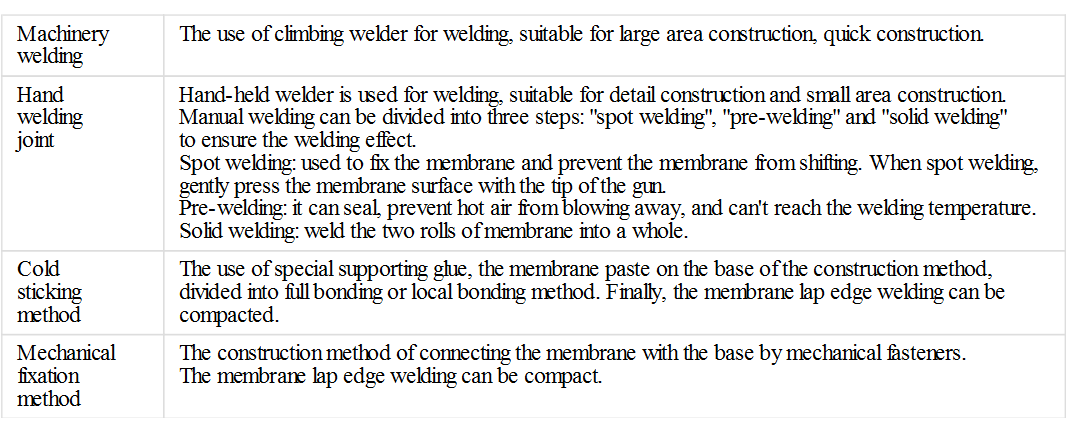

Construction Method

- Q: PVC waterproof membrane effect how

- 2, cold sticky method: the use of adhesive or miaolica for membrane and the grassroots, membrane and membrane bonding, and no need to heat the construction method.

- Q: Can a waterproofing membrane be used on rubber surfaces?

- Rubber surfaces, like roofs, decks, or rubber flooring, can benefit from the use of a waterproofing membrane. These membranes are designed to create a barrier that stops water from penetrating and harming the underlying surface. By applying a liquid or sheet membrane, it adheres to the rubber surface and forms a protective layer that prevents water from seeping through. This protective layer not only extends the lifespan of the rubber surface but also prevents problems like leaks or decay caused by moisture. However, it is crucial to ensure that the waterproofing membrane is compatible with the specific type of rubber surface being treated. Some membranes may not adhere properly or may cause damage to certain types of rubber. To guarantee proper application and compatibility, it is always recommended to consult with a professional or the manufacturer of the waterproofing membrane.

- Q: Can waterproofing membranes be used on concrete pools?

- Yes, waterproofing membranes can be used on concrete pools. Waterproofing membranes are designed to provide a barrier against water penetration and can be applied to various surfaces, including concrete. Concrete pools are susceptible to water leakage over time due to cracks or deterioration, and applying a waterproofing membrane can help prevent these issues. The membrane is typically applied to the pool's interior surface, creating a seamless and watertight seal. It is important to choose a high-quality waterproofing membrane specifically designed for use in swimming pools to ensure long-lasting and effective results.

- Q: How does a waterproofing membrane withstand freeze-thaw cycles?

- A waterproofing membrane is designed to withstand freeze-thaw cycles by being made of materials that are resistant to temperature changes and water infiltration. These membranes are typically composed of durable polymers such as polyurethane, polyethylene, or PVC, which have low permeability to water and can resist the expansion and contraction caused by freezing and thawing. During freeze-thaw cycles, water can enter small cracks and pores in a structure. When this water freezes, it expands, exerting pressure on the surrounding materials. This expansion can cause cracks to widen and weaken the structure, leading to water leakage and potential damage. However, a waterproofing membrane acts as a barrier, preventing water from penetrating the structure and reducing the potential for freeze-thaw damage. The membrane is installed on the exterior surface of the structure, forming a seamless and continuous layer that does not allow water to pass through. It adheres tightly to the surface and is flexible enough to accommodate the dimensional changes caused by temperature variations. Moreover, waterproofing membranes are often reinforced with other materials such as fabrics or meshes to enhance their strength and stability. These reinforcements further protect the membrane from damage during freeze-thaw cycles, ensuring its long-term effectiveness. In summary, a waterproofing membrane withstands freeze-thaw cycles by preventing water infiltration and resisting the expansion and contraction caused by freezing and thawing. Its composition, including durable polymers and reinforcements, makes it a reliable barrier against water penetration, reducing the risk of structural damage and maintaining the integrity of the protected surface.

- Q: Can a waterproofing membrane be used on concrete?

- Yes, a waterproofing membrane can be used on concrete. In fact, it is a commonly used method to prevent water penetration and protect concrete structures from moisture damage. A waterproofing membrane is a thin layer of material that is applied on the surface of the concrete to create a barrier against water and moisture. It can be made from various materials such as bitumen, rubberized asphalt, polyurethane, or acrylic. The membrane is typically applied in liquid or sheet form and adheres to the concrete surface to form a continuous and impermeable coating. This coating prevents water from seeping into the concrete, which can cause degradation, cracks, and other forms of damage. Waterproofing membranes are widely used in various concrete applications, including basements, foundations, roofs, and other structures that are exposed to moisture or water.

- Q: SBS Shale Waterproof Coil

- Advantages: toughness, easy to crack. Adapt to the changing structure of the roof. Disadvantages: shorter service life.

- Q: Can a waterproofing membrane be used for a school building foundation?

- A school building foundation can indeed utilize a waterproofing membrane. These membranes are specifically created to safeguard structures by preventing water from infiltrating. They are commonly employed in various construction scenarios, including building foundations. By applying a waterproofing membrane to the foundation walls, it can effectively shield the building from water-related harm and prevent issues caused by moisture, such as mold, decay, and structural damage. This is especially crucial for school buildings due to their extensive foundations and the possibility of heavy usage and water exposure. Thus, the use of a waterproofing membrane is a viable solution to ensure the durability and structural soundness of the school building foundation.

- Q: Is a waterproofing membrane resistant to saltwater or salt damage?

- Typically, a waterproofing membrane resists saltwater or salt damage. Its purpose is to create a barrier against water and moisture, making it suitable for use in marine environments or coastal areas. These membranes are made from materials that can withstand the corrosive effects of saltwater or salt. To ensure their resistance to saltwater or salt damage, proper preparation and sealing techniques are employed during installation. However, it is important to note that the level of resistance may vary depending on the type and quality of the membrane. Therefore, it is advisable to consult with a professional or the manufacturer to choose the appropriate membrane for the specific application and environment.

- Q: Can waterproofing membranes be used on shower walls?

- Yes, waterproofing membranes can be used on shower walls. These membranes are specifically designed to create a barrier against water, preventing leaks and protecting the underlying structure from moisture damage. Applying waterproofing membranes on shower walls is a common practice to ensure a watertight and durable shower enclosure.

- Q: Is a waterproofing membrane suitable for below-grade applications?

- Yes, a waterproofing membrane is suitable for below-grade applications.

Send your message to us

TPO/PVC High Polymer Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords