Root-puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Root-puncture Resistant Waterproofing Membrane:

Because the traditional waterproofing materials as well as ordinary polymer waterproof material, all kinds of waterproof coating can meet the requirements of building planting system, because these materials do not have root resistance, it is easy to plant root penetration, the building damage and leakage, directly led to the failure of the "planting green building system. And a PVC duplex root puncture resistant waterproofing materials in copper base as root membrane resistance, resistance to plants with long roots or rhizomes puncture performance, strong cohesive force, good stability, low temperature flexibility and good heat resistance, chemical corrosion resistance and radiation resistance is strong, for more than 20 years still showed good resistance waterproof performance.

2.Main Features of Root-puncture Resistant Waterproofing Membrane:

Waterproof and prevent plant root through the dual function.

Durable, resistant to cough up, tear resistance, resistance to fatigue

Tensile strength is high, the change of asphalt coating cover thickness is big

Corrosion resistance, resistance to mildew, good corrosion resistance

3.Specification of Root-puncture Resistant Waterproofing Membrane:

| Tensile Strength | 800N/5CM | |||

| Elongation at break | 40% | |||

| Heat resistance | 115℃ | |||

| Low temperature resistant | -35℃ | |||

| Thickness | ≥4mm |

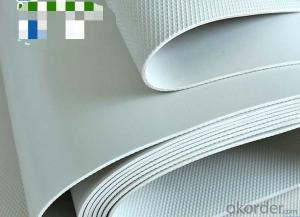

4.Root-puncture Resistant Waterproofing Membrane Images;

- Q: Can a waterproofing membrane be used in areas with high foot traffic?

- Yes, a waterproofing membrane can be used in areas with high foot traffic. Waterproofing membranes are designed to provide a protective barrier against water and moisture, making them suitable for various environments, including areas with heavy foot traffic. These membranes are commonly used in commercial buildings, such as shopping malls, hospitals, and office complexes, where foot traffic is frequent. However, it is important to choose the right type of waterproofing membrane that is specifically designed for high foot traffic areas. Some membranes are more durable and resistant to wear and tear, making them ideal for such environments. Additionally, proper installation and maintenance of the membrane are crucial to ensure its longevity and effectiveness in high foot traffic areas. Furthermore, it is worth considering the specific requirements of the area and consulting with professionals or manufacturers to determine the most suitable waterproofing membrane for the given conditions. Overall, with the right selection and proper installation, a waterproofing membrane can effectively protect areas with high foot traffic from water damage and ensure their longevity.

- Q: Can waterproofing membranes be used for planter boxes?

- Yes, waterproofing membranes can be used for planter boxes. Waterproofing membranes provide a protective barrier against moisture, preventing any water leakage that could damage the planter box or surrounding areas. This helps to preserve the longevity and integrity of the planter box, making it suitable for long-term use in outdoor environments.

- Q: Can a waterproofing membrane be used for a warehouse floor?

- No, a waterproofing membrane is not typically used for a warehouse floor. Instead, materials such as epoxy or concrete sealers are commonly used for warehouse floors to provide durability and resistance to heavy loads and foot traffic.

- Q: Is a waterproofing membrane resistant to solvents or chemical spills?

- Yes, a waterproofing membrane is typically resistant to solvents or chemical spills.

- Q: Are waterproofing membranes suitable for historical buildings?

- Yes, waterproofing membranes can be suitable for historical buildings. These membranes provide an effective solution for preventing water penetration and damage to the structure, helping to preserve the integrity and longevity of the building. However, it is essential to consider the specific requirements and characteristics of the historical building and select an appropriate membrane that is compatible with its materials and architectural features. Additionally, any waterproofing work should be done with sensitivity and care to ensure it does not compromise the historical value or aesthetics of the building.

- Q: How does a waterproofing membrane handle movement joints or cracks?

- A waterproofing membrane is designed to handle movement joints or cracks by providing a flexible and stretchable barrier that can accommodate the shifting or settling of a structure. When there are movement joints or cracks present, the membrane is applied in a way that creates a continuous and seamless layer over the surface. The flexibility of the waterproofing membrane allows it to move and adapt to changes in the structure, such as expansion or contraction, without compromising its integrity. This is especially important in areas where there is significant movement or where cracks are prone to develop, such as in concrete slabs or foundations. In the case of movement joints, the membrane is typically terminated or split at the joint to allow for movement without creating stress or tension on the membrane. This ensures that any movement or shifting of the structure does not cause the membrane to tear or fail. For cracks, the waterproofing membrane is applied directly over the surface, bridging the gap and sealing it off from water infiltration. The flexible nature of the membrane allows it to stretch and conform to the shape of the crack, effectively sealing it and preventing further water damage. Overall, a waterproofing membrane is designed to handle movement joints or cracks by providing a durable and flexible barrier that can accommodate structural movements and prevent water penetration. This helps to maintain the integrity of the structure and protect it from water damage.

- Q: Can a waterproofing membrane be used in conjunction with flooring materials?

- Indeed, flooring materials can be used in conjunction with a waterproofing membrane. It is actually quite common to advise the application of a waterproofing membrane while installing specific types of flooring, particularly in wet spaces such as bathrooms, kitchens, or basements. The waterproofing membrane functions as a shield against moisture, effectively thwarting water penetration that could potentially harm the flooring material or the subfloor. It provides safeguard against leaks, spills, and even excessive moisture in the atmosphere. Through the utilization of a waterproofing membrane, you can guarantee the longevity and sturdiness of your flooring, simultaneously upholding a waterproof and moisture-resistant environment.

- Q: What is the accounting subject of the waterproofing membrane

- Own spare, included in the project materials Waterproof sheet, used for sale, remember inventory goods

- Q: Can a waterproofing membrane be used in shower pans?

- Using a waterproofing membrane in shower pans is indeed recommended to prevent water leakage or damage to the underlying structure. This barrier prevents water from seeping through the shower pan and into the subfloor or surrounding walls, maintaining the integrity and longevity of the shower pan and the overall shower system. Furthermore, it also safeguards against mold and mildew growth, creating a safe and hygienic environment. Thus, incorporating a waterproofing membrane in shower pans is crucial for a durable and water-resistant shower installation.

- Q: Can a waterproofing membrane be used for crawl spaces?

- Yes, a waterproofing membrane can be used for crawl spaces. Waterproofing membranes are commonly used in crawl spaces to prevent moisture and water infiltration, which can cause structural damage and promote mold growth. By installing a waterproofing membrane, it creates a barrier that keeps moisture out and helps maintain a dry and healthy crawl space environment.

Send your message to us

Root-puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords