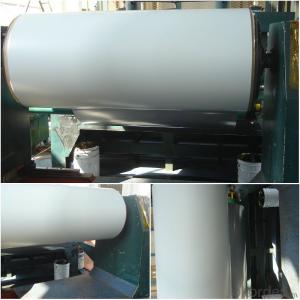

Aluminum Coil Stock White

Aluminum Coil Stock White Related Searches

Aluminum Coil White White Aluminum Coil Stock White Aluminum Coil 24 White Aluminum Coil Stock Aluminum Trim Coil White White Aluminum Trim Coil Black Aluminum Coil Stock Aluminum Coil Stock Colors Coil Aluminum Stock Coil Stock Aluminum Aluminum Siding Coil Stock Anodized Aluminum Coil Stock Aluminum Coil Stock Lowe's Alcoa Aluminum Coil Stock Painted Aluminum Coil Stock Aluminum Coil Stock Brake Aluminum Coil Stock For Sale Aluminum Wire Coil Colored Aluminum Coil Stock White Aluminum Flashing Coil Wood Grain Aluminum Coil Stock Aluminum Trim Coil Stock Aluminum Coil Stock Color Chart Vinyl Coated Aluminum Coil Stock White Aluminum Foil Alcoa Aluminum Coil Stock Colors Aluminum Coil Stock Thickness Aluminum Coil Stock Prices Aluminum Gutter Coil Stock Aluminum Coil Stock GaugeAluminum Coil Stock White Supplier & Manufacturer from China

Aluminum Coil Stock White is a versatile product that encompasses a range of aluminum coils with a white finish, suitable for various industries and applications. These coils are known for their durability, corrosion resistance, and lightweight properties, making them ideal for construction, automotive, aerospace, and packaging sectors. The product's white finish adds an aesthetic appeal, which is particularly useful in applications where appearance is a crucial factor.The application and usage scenarios of Aluminum Coil Stock White are diverse, as it can be utilized in a multitude of ways depending on the specific requirements of the project. For instance, it can be used in the manufacturing of aluminum composite panels, which are popular in the construction industry for their strength and visual appeal. Additionally, it is used in the automotive sector for the production of body panels and other components that require a combination of strength and light weight. In the packaging industry, Aluminum Coil Stock White is employed for creating food and beverage containers, taking advantage of its non-toxic and recyclable properties.

As a wholesale supplier, Okorder.com boasts a large inventory of Aluminum Coil Stock White, catering to the needs of businesses and industries that require this product in bulk. With a comprehensive selection and competitive pricing, Okorder.com ensures that customers have access to the high-quality aluminum coils they need, backed by reliable customer service and efficient shipping options. This makes Okorder.com a go-to source for businesses looking to purchase Aluminum Coil Stock White in large quantities for their operations.

Hot Products