Color Aluminum Coil Stock for Aluminum Coil Gutter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil Stock used for Aluminum Coil Gutter

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Coil Stock used for Aluminum Coil Gutter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil Stock used for Aluminum Coil Gutter

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

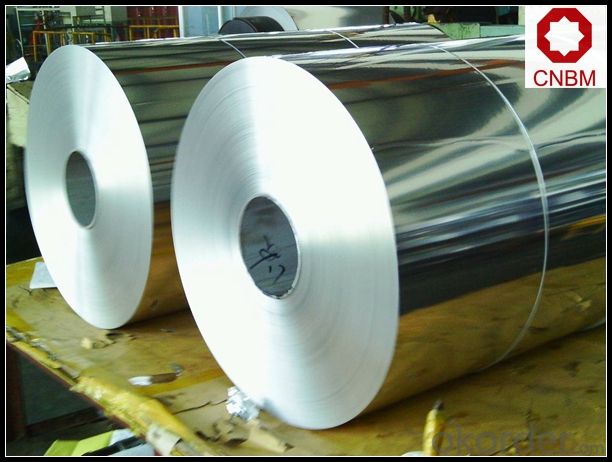

5. Image of Aluminum Coil Stock used for Aluminum Coil Gutter

6. Package and shipping of Aluminum Coil Stock used for Aluminum Coil Gutter

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ of

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Explain the distinctions among various welding equipment used specifically for joining aluminum coils.

- <p>Different types of welding equipment for aluminum coils include Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Resistance Welding (RW). GTAW, also known as TIG welding, uses a non-consumable tungsten electrode and produces high-quality welds with minimal distortion. GMAW, or MIG welding, uses a continuous wire feed as the electrode and is faster but may not be as precise. Resistance Welding involves using electrical current to heat the metals at the joint, which is quick and efficient but not suitable for all aluminum alloys. Each method has its advantages and is chosen based on factors like weld quality, speed, and the specific aluminum alloy being welded.</p>

- Q: What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils have a wide range of potential applications due to their unique characteristics. They are commonly used in architectural and construction projects for cladding, roofing, and facades, as their anodized coating provides excellent durability, corrosion resistance, and aesthetic appeal. Other potential applications include electronic casings, automotive trim, signage, cookware, and industrial components, where the anodized coating offers protection against wear, abrasion, and chemicals. Additionally, the ability to dye the anodized coating enables customization and allows for decorative uses in jewelry, artwork, and consumer goods.

- Q: Can aluminum coils be used in the construction industry?

- Yes, aluminum coils can be used in the construction industry. Aluminum is a lightweight and durable material with excellent corrosion resistance, making it suitable for various construction applications like roofing, siding, gutters, and HVAC systems. Aluminum coils are commonly used to create custom shapes and profiles that meet specific project requirements.

- Q: If so why does an aluminum bend or get nicked or break quickly?

- It depends on how you set the criteria of comparison. If you go by volume, Aluminum isn't stronger. That's why a steel can is stronger than one of similar size and thickness. If you go by weight, aluminum is said to be stronger. Let's say we were looking to create a wall, spec'ed to a particular height and width, and just thick enough to hold back a given PSI of pressure. The aluminum one would have to be thicker to have the strength to hold back the pressure, but it'd be lighter than the steel equivalent. Also, the ease by which a material can be nicked isn't an indicator of strength but of hardness. Harder, isn't necessarily stronger.

- Q: What are the potential risks of using aluminum coils in specific applications?

- There are several potential risks associated with using aluminum coils in specific applications. Firstly, aluminum is a highly reactive metal and can undergo oxidation, leading to the formation of aluminum oxide. This oxide layer can be protective in some cases, but in certain environments, such as acidic or alkaline conditions, it can break down and result in corrosion of the aluminum coils. This corrosion can compromise the structural integrity of the coils and reduce their lifespan. Secondly, aluminum coils have relatively low strength compared to other metals, such as steel. This can make them susceptible to deformation or damage under heavy loads or high pressure conditions. In applications where the coils are exposed to significant mechanical stress, they may be more prone to bending or cracking, leading to potential failure. Furthermore, aluminum has a relatively low melting point compared to other metals, such as copper or iron. This means that in applications where the coils are subjected to high temperatures, such as in heating or cooling systems, there is a risk of the aluminum coils melting or deforming. This can result in system malfunctions, reduced efficiency, or even safety hazards. Another potential risk of using aluminum coils is related to their electrical conductivity. While aluminum is a good conductor of electricity, it has a higher resistance compared to copper. This can lead to increased power losses and reduced energy efficiency in electrical applications. Additionally, aluminum coils may also be more prone to electrical arcing or sparking, which can pose a fire hazard. Finally, it is worth mentioning that aluminum is a lightweight metal, which can be advantageous in certain applications. However, this also means that aluminum coils may have lower durability and resistance to physical impacts or external forces compared to heavier metals. In environments where the coils are exposed to vibrations, impacts, or other mechanical stresses, they may be more susceptible to damage or premature failure. Overall, while aluminum coils offer various benefits, including light weight, good thermal conductivity, and resistance to corrosion, it is important to carefully consider the potential risks associated with their use in specific applications. Proper design, maintenance, and compatibility with the operating conditions are crucial to mitigate these risks and ensure the safe and effective performance of aluminum coils.

- Q: How do aluminum coils contribute to improved indoor air quality?

- Aluminum coils contribute to improved indoor air quality by efficiently removing heat and moisture from the air, preventing the growth of mold and mildew. Additionally, aluminum coils are resistant to corrosion, reducing the risk of air contamination caused by rust or other harmful particles.

- Q: could you please help me find information of the element aluminum??? all the information i can get will be great... thanks very mucho.... who discovered? where can i find pictures of it?

- hi ive found this: Aluminium is a silvery white member of the boron group of chemical elements. It has the symbol Al and its atomic number is 13. It is not soluble in water under normal circumstances. Aluminium is the most abundant metal in the Earth's crust, and the third most abundant element, after oxygen and silicon. It makes up about 8% by weight of the Earth's solid surface. Aluminium is too reactive chemically to occur in nature as a free metal. Instead, it is found combined in over 270 different minerals.[5] The chief source of aluminium is bauxite ore. Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are very important in other areas of transportation and building. Its reactive nature makes it useful as a catalyst or additive in chemical mixtures, including ammonium nitrate explosives, to enhance blast power. Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. Aluminium is nonmagnetic and nonsparking. It is also insoluble in alcohol, though it can be soluble in water in certain forms. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[6] Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

- Q: Can aluminum coils be used for electrical applications?

- Yes, aluminum coils can be used for electrical applications. Aluminum is a highly conductive material and is commonly used in various electrical applications such as transformers, motors, and generators. It offers advantages such as lightweight, good thermal conductivity, and cost-effectiveness, making it a suitable choice for electrical coils.

- Q: Is it possible to create a baking pan using aluminum coil material?

- <p>Yes, you can use aluminum coil to make a baking pan. Aluminum is a popular material for baking pans due to its excellent heat conductivity, which allows for even heating. When creating a baking pan from aluminum coil, ensure that the coil is food-grade and that the edges are properly sealed to prevent any sharp edges. It's also important to consider the thickness of the aluminum, as a thicker gauge will distribute heat more evenly. Always follow safety guidelines and ensure that the aluminum coil is suitable for use in an oven.</p>

- Q: This question asks for precautions that should be taken when handling aluminum coils to ensure safety.

- <p>When handling aluminum coil, it's crucial to follow safety measures to prevent accidents and injuries. Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and closed-toe shoes. Ensure that the work area is well-lit and free from clutter to avoid trips and falls. Use lifting equipment, such as cranes or forklifts, for heavy coils and never attempt to lift them manually. Keep the coils dry to prevent corrosion and ensure they are stored properly on wooden pallets or racks to prevent damage. Be aware of the risk of aluminum dust, which can be a fire hazard, and ensure proper ventilation is in place. Regularly inspect the coil for any sharp edges or damage that could cause injury. Always follow the manufacturer's guidelines and adhere to local safety regulations.</p>

Send your message to us

Color Aluminum Coil Stock for Aluminum Coil Gutter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords