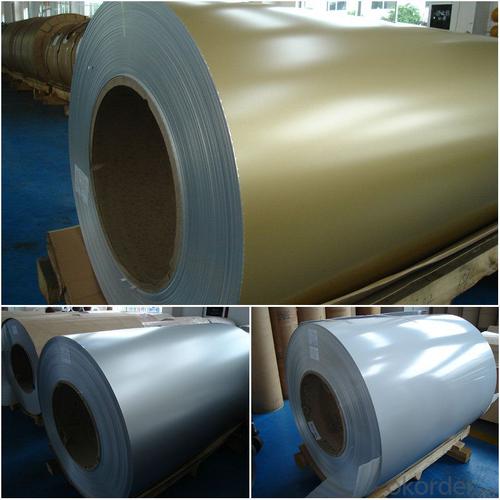

Aluminum Coil Price Per Pound - Color Prepainted Aluminum Panel Sheet 3105h44

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum magnesium alloy Al-Mn

First, the raw materials:

Al-Mn-Mg aluminum alloy is in generalbased on the addition of manganese and magnesium components, and its productsthan the average tensile strength and elongation strength aluminum, doubled,and its corrosion resistance to oxidation has been further enhanced in Metalindustry is known as rust aluminum. Therefore, Al-Mn-Mg alloy 3004 with arust-proof characteristics and high strength, wide range of uses.

Second,the Al-Mn-Mg alloys the characteristics of color coated aluminum

Colorcoated aluminum magnesium alloy Al-Mn alloy is used for the 3004 state of theAl-Mn-Mg aluminum alloy substrate, after de-ester, cleaning, passivation layerprocessing, and then painting on this basis, the international most advancedlevel of KANAR500 and HYLAR5000 Series Fluorocarbon (PVDF) resin coating, thecolor coated aluminum manganese alloy known international companies use theU.S. PPG, Sweden and the United States Weishi Bo Beca companies paint company,its products by the natural light exposure, Florida testing, with more than 20years of weathering quality assurance. Color coated aluminum magnesium alloyAl-Mn advantages of raw materials, its products have a high strength, corrosionresistance, high weather resistance and other characteristics, and according totheir own customers were asked to choose a different color palette, you cancolor integration, can co-exist to gorgeous effect.

Third,Al-Mn-Mg alloys the use of color coated aluminum

Ourcompany specializes in aluminum color coated aluminum manganese alloy has beenwidely used in large factories, exhibition halls, stadiums, airports, trainstation roof and ceiling decorative envelope system board. Thickness of thealuminum can choose different color coated aluminum magnesium alloy ofmanganese, by cutting, pressing, punching, bending and other follow-up moldingprocess for large span, the larger the overall roof, wall decorative panelsused in construction; You can also cut into small panels by bending, stampingmold, etc., for indoor decorative roof plate; also with polyurethane foam,bonded aluminum honeycomb composite construction for energy-saving decorativewall plates.

Fourth,the development prospects

As the field of building decoration materials, the continuous improvementrequirements, as poor performance of color coated steel corrosion, rust, yellowrust after a large amount of the deficiency of serious impact on the building'soverall appearance, the urgent need to develop a color plate with bothstrength, but also overcome the shortcomings of color-coated steel, while thereare long-term durability of new materials, building decoration, used inairports, commercial buildings, train stations, subways, hospitals and otherarchitectural decoration. The Al-Mn-color coated aluminum magnesium alloymaterials precisely meet these requirements, with the expanding domesticdemand, strengthen public infrastructure under the principle of color coatedaluminum magnesium alloy of manganese will become an increasingly widespreaduse of aluminum, a good prospect.

Embossed color coatedaluminum coil

the company can produce the aluminum coil pattern are: classic orange peel pattern,and variation orange peel pattern (also called as bugs’ pattern). Thicknessspecification is 0.2mm ~ 0.6mm, width less than 1600mm. The materials used arefluorocarbon coated aluminum, polyester coated aluminum coil, aluminum roll,light aluminum, brushed aluminum rolls.

By embossing the surface of aluminum coil elegant, streamlined good, solidsense. Embossed aluminum coil aluminum coil can not only increase the thicknessof the aluminum coil thickness of 0.1 ~ 0.25mm. At the same time can enhance thestrength of aluminum coil, stiffness, and does not affect the original surfacelayer of the aluminum coil with the performance.

Embossed aluminum coil, wide range of uses. Mainly used for indoor and outdoordecoration, freezer, refrigerator, decorative aluminum products, bags, centralair conditioning and ventilation nozzles, and mechanical equipment enclosuresand so on. Is a new decorative material.

Thecompany has two production lines embossed aluminum coil: one for the simpleformula: put through Unwinder mechanical embossing roll winder windingembossed, convenient and quick. Another is the compound: that is embosseddirectly into the device placed in the coating line, coating and embossingsynchronization, when the coating needs of embossed aluminum coil, through thehydraulic transmission, the embossing machine, under the pressure rollerengagement, aluminum coating line directly in the embossing roll, fast, lowcost, no turnover.

Thickness range

0.2mm—0.6mm

Width range

800mm—1590mm

Technical parameters

Aluminum thickness | Coating thickness | MEK | T-bend | Impact | Adhesion | Pencil hardness | Boiling water proof |

0.20-0.60mm | ≥18±1um | ≥100times | ≤3T | 50kg.cm | 0grade | ≥HB | no change within 2 hours |

Performance and Application

Embossed aluminum coil for roofing is coatedwith high-performance polyester paints. And its each performance index is up toor exceeds the national standard. With its glorious colors, little chromatism,strong impact and easy machinability, the product serves as a premium materialin roofing, electric appliances, etc.

Export sea worthy packing,coilOD and through coil ID covered with water proof polythene film to avoidcondensation and white rusting,over the polythene film the coils covered withhard cardboard.Coils should be place on wooden pallets.Coils ID contain hardinner cardboard sleeve.

Used for manufacture decorative materials, such as aluminum veneers, ACP aluminum composite panels, honeycomb panels, aluminum roofing, lighting decoration, household electrical appliances, food package(such as pop can cover and ring-pull),and furniture etc.:

1) Exterior applications: wall cladding, facades, roofs and canopies, tunnels, column covers or renovations;

2) Interior applications: wall cladding, ceilings, bathrooms, kitchens and balconies;

3) Advertisement and market applications: display platforms, signboards, fascias and shop fronts;

4) Transport and industrial applications

- Q: What are the production processes of aluminum coil and what are the functions of various industrial furnaces in the production of aluminum? The more detailed, the better. Thank you! Points!

- There are aluminum annealing furnace, aluminum alloy quenching furnace, aging furnace and smelting furnace.

- Q: What are the common surface finishes available for aluminum coils?

- Aluminum coils come in various surface finishes, each with its own advantages and aesthetic appeal. One popular option is the mill finish, which is the standard finish applied directly from the mill. It provides a smooth and shiny surface without any additional treatments or coatings. Another common choice for aluminum coils is the anodized finish. This involves an electrochemical process that creates a durable and corrosion-resistant layer on the aluminum's surface. Anodized finishes can be clear or colored, offering a wide range of design options. Painted or coated finishes are also widely used for aluminum coils. This involves applying a layer of paint or coating to enhance appearance and protect against corrosion. The color, gloss level, and texture of painted finishes can be customized to suit different design needs. Brushed finishes are often employed for aluminum coils, creating a pattern of fine lines or scratches on the surface. This unique texture adds visual interest to various applications. Laminating is another option for aluminum coil finishes. It involves applying a thin layer of film or other material to provide additional protection against scratches, UV rays, and other elements. The laminated finish can be glossy or matte, depending on the desired look. In summary, the available surface finishes for aluminum coils include mill finish, anodized finish, painted or coated finish, brushed finish, and laminated finish. Each finish has its own advantages and can be chosen based on specific requirements such as aesthetics, durability, corrosion resistance, and customization options.

- Q: hello, i have been recently studying the production of aluminum from aluminum dross (recycling of aluminum) .this chemical equations represents the hydrolization of sodium aluminate to obtain aluminum hydroxide :Na2Al2O4 + 4H2O -----------gt; 2Al(OH)3 + 2NaOHafter that the next step is to produce Al2O3the next step to obtain Aluminum is to pass a current through the solution (electrolysis)this is the part that i don't get .... how could we electrolyze Aluminium oxide to produce aluminum if we are recycling aluminum ... i mean electrolysis consumes most of the energy and is very expensive .... so how do electrolysis be used in the recycling industry...please answer ... all answers are really appreciated ....and correct me if my informations are wrong...

- As Aluminum dross composition will vary from different sources Electrolytic aluminium dross w(Al)25.58, w(Al2O3)31.55, w(SiO2)5.56, w(Na2O)2~3, w(MgO)2.0~3.0, w(CaO)2.00, w(FeO)+ w(MnO)1.0 Cast aluminum dross w(Al)10, w(Al2O3)50~60, w(SiO2)3.0~5.0, w(Na2O)1.0~1.5 w(MgO)2.0~3.0, w(CaO)1. 5~3.0, w(FeO)+ w (MnO)1.0 The most popular way is mechanical recover aluminum from aluminum dross. Rotary furnace and aluminum dross recovery machine can do this work easily and effectively. You can put heating flux in the processing to get the certain temperature for the dross, them aluminum dross can be processed in the rotary furnace or aluminum dross processing machine, aluminum will be recycled from aluminum dross. It is automatic and that is such simple!

- Q: What are the main causes of aluminum strip rolling?

- Different thickness analysis is not the same, is curly after the thickness of the upper rib, or out of the roll can be visual?

- Q: Can aluminum coils be used for HVAC systems?

- Yes, aluminum coils can be used for HVAC systems. They are commonly used due to their durability, resistance to corrosion, and efficiency in transferring heat.

- Q: This question asks about the economic impact of aluminum coils, which are a key material in various industries.

- <p>Aluminum coils significantly impact the economy by driving growth in various sectors. They are vital in construction, automotive, aerospace, and packaging industries due to their lightweight, durability, and recyclability. The aluminum coil market stimulates manufacturing, job creation, and technological advancements. Additionally, their high demand supports the growth of the aluminum industry, influencing trade and contributing to GDP. The recycling of aluminum coils also reduces energy consumption and environmental impact, further benefiting the economy by promoting sustainable practices.</p>

- Q: Can aluminum coils be used for food processing equipment?

- Food processing equipment can indeed utilize aluminum coils. The reason behind the popularity of aluminum in this context lies in its remarkable thermal conductivity, resistance to corrosion, and lightweight properties. The food industry heavily relies on aluminum for a variety of applications, including heat exchangers, evaporators, and condensers. Specifically engineered to effectively transfer heat and uphold a consistent temperature, aluminum coils prove to be ideal for food processing equipment that demands precise temperature control. Moreover, aluminum is a non-toxic material, guaranteeing that it does not contaminate the processed food. Consequently, aluminum coils establish themselves as a dependable and secure choice for food processing equipment.

- Q: Can aluminum coils be used in automotive suspension systems?

- Automotive suspension systems can utilize aluminum coils. Aluminum, a lightweight and sturdy material, provides numerous advantages for suspension components. Its high strength-to-weight ratio allows it to handle heavy loads without burdening the vehicle with unnecessary weight. This can enhance fuel efficiency and overall performance. Furthermore, aluminum is resistant to corrosion, making it particularly valuable for automotive suspension systems exposed to harsh weather conditions and road debris. By incorporating aluminum coils, manufacturers can ensure that suspension components have a longer lifespan and require less maintenance. In addition, aluminum coils possess superior heat absorption and dissipation capabilities compared to materials like steel. This aids in preventing overheating and mitigating the risk of suspension failure, especially during intense driving conditions or off-road usage. However, it is important to note that the use of aluminum coils in automotive suspension systems may entail certain compromises. Although aluminum is lighter and more resistant to corrosion, it may not be as strong as steel. Therefore, manufacturers must meticulously design and engineer the suspension system to ensure it can withstand necessary loads and provide sufficient support and stability for the vehicle. In summary, aluminum coils can be effectively employed in automotive suspension systems, offering benefits such as lightweight construction, corrosion resistance, and efficient heat dissipation. Nevertheless, manufacturers must carefully consider the specific requirements and trade-offs associated with aluminum usage in suspension components to ensure optimal performance and safety.

- Q: Aluminum coil thickness measurement, real-time measurement of aluminum coil thickness value, you can use displacement sensor?

- Yes, the two sensors measure and measure the thickness

- Q: I am concerned about the environment so I collect empty aluminum cans off the street when I walk my dog. Right now I have 3 large garbage bags full of crushed aluminum can. The problem is... some of the cans have dirt on and in them. Some of thoroughly flattened ones may even have small pebbles embedded in them. Will these be accepted at the recycling facility? I'm guessing it doesn't matter because when they melt them any organic materials will burn away and any dirt particles or small pebbles will be separated from the molten aluminum. What do you think?

- No problem with dirt and dust.

Send your message to us

Aluminum Coil Price Per Pound - Color Prepainted Aluminum Panel Sheet 3105h44

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords