Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,degrease , chemical treatment and liquid dope with several layers of color

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable of decoration

• Superior workability

• Good visual effect

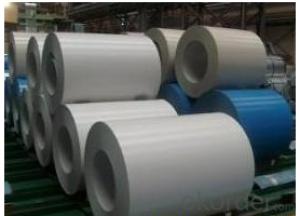

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Available Painting OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 5+20microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

5.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

- Q: Hello,I have been thinking about buying a Tungsten Carbide Diamond wedding band for my husband but one of my family members keep telling me that Tungsten Carbide is merely steel and hence, a low quality metal, therefore, I shouldn't buy it. I don't really know much about it. Please if anyone can tell me more about this metal? Thanks.

- Tungsten is not steel. Tungsten is a chemical element. What they do is add an alloy mixture to tungsten and it turns into Tungsten Carbide. You want to find a ring with a nickel alloy, some manufacturers cheap out and add cobalt instead. Make sure the ring you buy does not contain cobalt. Steel is an alloy consisting mostly of iron, with a carbon.

- Q: How are steel coils used in the production of food processing machinery?

- Steel coils are used in the production of food processing machinery as they are commonly used to create the structural frames and components of the machinery. Additionally, steel coils are often used to manufacture cutting blades, conveyor belts, and various other parts that require strength and durability in the food processing industry.

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- Broken Steel's quests activate once you have beaten the final mission in the purifier. If you have already beaten the game, then you should just go back to the purifier and beat it again, since normally you wouldn't be able to continue to play the game once you have beaten it without Broken Steel. If you were able to continue playing the game, then it's likely that whatever mod you used is interacting with the game and making it impossible for Broken Steel to activate.

- Q: How are steel coils used in the production of bridges?

- Steel coils are used in the production of bridges as they provide a reliable and strong structural material. These coils are shaped and formed into various components, such as beams and girders, which are then assembled to create the bridge's framework. The steel coils' durability and high tensile strength make them ideal for supporting heavy loads and withstanding the forces experienced by bridges.

- Q: How are steel coils processed for different levels of hardness?

- Steel coils can be processed for different levels of hardness through a combination of heat treatment and mechanical processes. To increase the hardness, the coils undergo a process called quenching and tempering. This involves heating the steel to a specific temperature, followed by rapid cooling (quenching) to create a hardened structure. Subsequently, the coils are reheated to a lower temperature and held there for a specific duration (tempering) to achieve the desired level of hardness. Other mechanical processes, such as cold rolling or cold drawing, can also be employed to further enhance the hardness of the steel coils.

- Q: What materials are used to make steel coils?

- Steel coils consist primarily of steel, an alloy primarily composed of iron and carbon. The choice of steel type for coil production depends on the desired properties and applications. Carbon steel is typically the preferred option due to its strength, durability, and versatility. Additional alloying elements, like manganese, silicon, nickel, or chromium, may be incorporated to enhance specific steel characteristics or properties. To produce steel coils, the raw materials are melted, the molten steel is refined, and specialized equipment and processes are employed to shape it into coils.

- Q: I'm going to buy a guitar for beginners and i wondered what strings are better steel or nylon?

- Yeah, you have some really bad answers here. You don't buy a nylon string guitar because you are a beginner, you buy one because you want to play classical music. You also cannot move between nylon and steel strings on the same guitar. Unless you want to play classical finger style music you need a steel string guitar. Just have extra light strings put on it and you can most likely have the action lowered a bit also, both of which will make it easier on the fingers. But the bottom line is this, if you want to play guitar you will have to go through a stage where you fingers get a little tender. Just keep your practice sessions short in the beginning, like 15 - 20 minutes at a time until the calluses build up.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using heavy-duty cranes and specialized equipment. When loading, the coils are lifted from the dockside or storage area using a crane with strong lifting capacity. They are carefully positioned onto the ship's deck, ensuring proper balance and securement to prevent any damage during transit. Unloading is done in a similar manner, with the crane carefully lifting the coils from the ship's deck and placing them onto the dock or designated storage area. Throughout the process, safety protocols are followed to ensure the smooth and efficient handling of these heavy and valuable cargo.

- Q: What is the thickness range of steel coils?

- The thickness range of steel coils can vary depending on the specific application and industry requirements. However, generally, the thickness range of steel coils can range from as thin as 0.005 inches (0.13 mm) to as thick as 0.5 inches (12.7 mm) or even more.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- There is no way you could make a 110 floor building out of concrete.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords