Coil Aluminum Stock for Composite Panel Coating Aluminum Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The Specification of Coated Aluminium Foil

1)Coil width:upon request,max up to 1550mm

2)Coil thickness:0.02-3.0mm

3)Internal diameter: 150mm, 405mm, 505mm

4)Coil weight: 1.5-4MT/coil

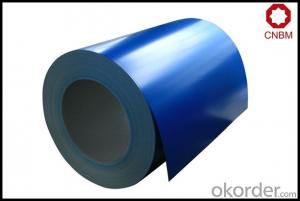

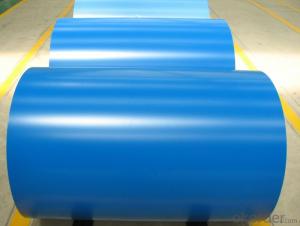

5)Coating: PE & PVDF color paiting

coated emboss aluminum coil/metal roofing

| |

Aluminum Temper and Grade | Alloys: 1100, 1050, 1100, 3003, 3105, 8011 in a range of standard Temper: O-H112 |

Widths | Max up to 1600mm |

Thickness | 0.02-3.0mm |

Coating | PE or PVDF |

Color | AS per the RAL |

Weight | 1.5-4MT/Coil as per your request |

Packing Detail | Wooden pallet either eye to side or eye to sky

|

Application | Building material such as metal ceiling, roofing, wall cladding panel; Automobiles, etc. |

PVDF Coated:

Coated Aluminum Coil features with super durability and weather resistance,and better properties to anti-acid,anti-alkali,keeping more than 15 years without fading in using as external wall cladding.

The Main Features of Aluminium Coated Coil:

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

The Imagin

FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C,T/T, West Union,etc.

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- There are great bats that are made out of each, but I generally tend to think that composite bats have better performance. There are aluminum bats that may be better than a given composite, but generally a high-end composite will be better than a high-end aluminum. Composites tend to have larger sweet spots, some span the entire length of the barrel, and the ball will still travel well if hit towards the outside of the sweet spot. contact hitters should look towards composites, because their slower swings will be compensated for with the spring action of the composite material. I think aluminums are better for power hitters because that material has been used for decades and the weight distribution has been better perfected for harder swings.

- Q: aluminum foil production of ERP software, requiring a comprehensive production process, and have special assistance to pre operation, the best price is reasonable

- Aluminum foil and aluminum coil production is a typical manufacturing type. With ERP, you can manage all the production processes, carry out cost accounting and voucher making, and can download the long-term trial.

- Q: Are aluminum coils resistant to mold and mildew?

- Yes, aluminum coils are highly resistant to mold and mildew. Aluminum does not provide a favorable environment for mold or mildew growth, making it an excellent choice for applications where moisture and humidity are concerns.

- Q: Can aluminum coils be used in power generation facilities?

- Aluminum coils are indeed suitable for use in power generation facilities. Aluminum, being a highly conductive material, offers numerous benefits for power generation applications. Its exceptional thermal conductivity allows for efficient heat transfer from the coils, a critical factor in cooling systems within power generation facilities. Moreover, aluminum's lightweight nature simplifies handling and installation, setting it apart from metals such as copper. This lightweight attribute also contributes to cost savings by reducing overall equipment weight. Additionally, aluminum's corrosion resistance is particularly valuable in power generation facilities, which frequently operate in challenging environments. In conclusion, considering their conductivity, thermal efficiency, lightweight nature, and corrosion resistance, aluminum coils present a feasible choice for power generation facilities.

- Q: How do aluminum coils compare to fiberglass coils in terms of weight?

- Aluminum coils are generally lighter in weight compared to fiberglass coils. Aluminum is known for its lightweight properties, making it an ideal choice for various applications, including coil manufacturing. Fiberglass, on the other hand, tends to be denser and heavier than aluminum. This weight difference can have several advantages when it comes to installation and transportation. Lighter aluminum coils are easier to handle, require less effort to install, and can be more cost-effective in terms of shipping and logistics. Additionally, the reduced weight of aluminum coils can contribute to overall energy efficiency in HVAC systems, as it requires less power to move and circulate air through the coils. However, it's worth noting that the weight comparison between aluminum and fiberglass coils may vary depending on the specific design and thickness of the materials used.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry due to its high strength-to-weight ratio. Its corrosion-resistant properties also make it an ideal choice for fuel tanks, as it can withstand the harsh conditions and chemicals found in aviation fuel. The use of aluminum coils allows for efficient manufacturing processes, as they can be easily formed and welded into the desired tank shape. Additionally, aluminum has excellent thermal conductivity, which helps dissipate heat generated during flight and prevents the fuel from overheating. Overall, aluminum coils are a suitable and widely-used material in the production of aircraft fuel tanks.

- Q: Can aluminum coils be used in the production of aluminum honeycomb panels?

- Yes, aluminum coils can be used in the production of aluminum honeycomb panels. Aluminum honeycomb panels are made by bonding aluminum sheets to a honeycomb core material, usually made of aluminum as well. The aluminum coils are typically used to produce the aluminum sheets that form the outer skin of the panels. These coils are rolled into thin sheets and then cut to the desired dimensions before being bonded to the honeycomb core. The use of aluminum coils allows for efficient and cost-effective production of aluminum honeycomb panels, as they can be easily formed and processed into the required shape and size. Additionally, aluminum is a lightweight and durable material, making it an ideal choice for the production of honeycomb panels used in various industries such as aerospace, construction, and transportation.

- Q: I'm ball milling aluminum into powder and I have filled the canister with some water to prevent the aluminum from igniting. The powder has begun to dissolve in the water. I'd like to know the best way to remove the dissolved aluminum from the water so I can get to the powder.There is around of cup of water in the canister, just to give an idea of the situation.

- Boil the water. The water will evaporate, leaving the aluminum behind.

- Q: Are aluminum coils susceptible to warping or bending?

- Yes, aluminum coils are susceptible to warping or bending. Aluminum, although lightweight and highly corrosion-resistant, is a relatively soft metal compared to other materials like steel. This means that it is more prone to bending or warping under certain conditions. Factors such as excessive heat, heavy loads, or improper handling can cause aluminum coils to deform. It is important to handle and store aluminum coils carefully to prevent any damage or distortion. Additionally, proper installation techniques and maintenance practices can help minimize the risk of warping or bending.

Send your message to us

Coil Aluminum Stock for Composite Panel Coating Aluminum Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords