1145 H19 Laminated Raw Aluminum Coil from China 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated Raw Aluminum Coil (3003 H14)

Product Description:

Laminated Raw Aluminum Coil is designed for many fields such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain walls, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc. Laminated Raw Aluminum Coil is hard and durable, even under the blazing sun. You can choose the right alloy for your habitation and we will do our best to meet your requests.

Product Features:

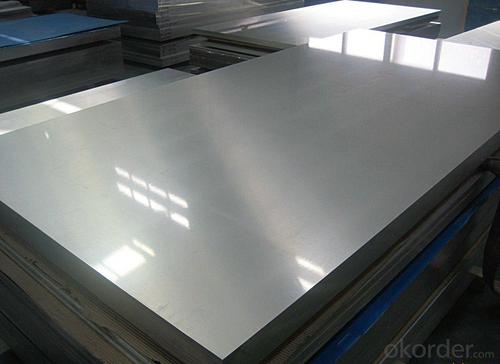

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

Product Applications:

Product Specifications:

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-100mm |

Width: | 30mm-1700mm |

Product Images:

Production of Hojas/Laminas de Aluminio natural 3003 H14

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Aluminium Metal - The Highly Conductive Property

Aluminium metal is the most abundant in the earth's crust but found only in combination, chiefly as an ore called bauxite. It also occurs in gemstones such as topaz, garnet, ruby and sapphire. It is found combined in over 270 different minerals. The metal is highly conductive and has great thermal properties and these properties are used for the various needs of the industries. Aluminium is silvery-white in colour.

The metal is used in various industries like building and construction, power transmission lines, photoengraving plates, cookware and other consumer goods, tubes for ointments and pastes. Global production of aluminium in the year 2005 was 31.9 million tonnes. This comes after iron consumption that was 837.5 million tonnes in the same year.

Pure aluminium has a low tensile strength, but if they are processed with proper heat and mechanics, they can be the strongest metal. Alloys formed with copper, zinc, magnesium, manganese and silicon are used in various industries.

Aluminium metal is extensively used in transportation industry. The use in aircraft and automobiles are well-known. A wide range of household items ranging from cooking utensils to baseball bats and watches are made of aluminium and its alloys. The consumer electronics are enclosed in the shells made of aluminium as they would not add to the weight of the equipment. Aluminium is used for making drinking cans, foil wrappings, bottle tops and foil containers that are extensively used in food and beverage industry. This is more effective as the metal is non-toxic and aromaless.

Powdered aluminium is used in paint and also forms an essential ingredient of the pyrotechnics like solid rocket fuels. The combination of properties light weight and great strength makes it useful in construction industry like window, doors, street lighting poles and sailing ship masts.

The highly conductive property of the metal makes it ideal to be used in electrical transmission lines for power distribution, heat sinks for electronic appliances such as transistors and CPU. About 1 kilogram of aluminium conducts almost twice as much electricity as 1 kilogram of copper. However, use of aluminium in household wiring has been found to be hazardous. Due to its ductile nature and corrosion resistance, the metal is used for electrical applications like TV aerials, satellite dishes and is the standard base for bulbs.

Aluminium is a recyclable material and many products can be made from the old form. Even the silver helium balloons that are commonly seen in birthday parties are covered with a thin, evaporated coating of aluminium metal over the tough plastic.

- Q: Are aluminum coils suitable for interior design applications?

- Aluminum coils are indeed a fitting choice for interior design purposes. The versatility of aluminum as a material presents a multitude of advantages for interior design endeavors. To begin with, aluminum possesses a lightweight nature, ensuring ease of handling and installation. This quality proves particularly advantageous for projects necessitating extensive installations or suspended ceilings. Moreover, aluminum coils exhibit exceptional durability and corrosion resistance, guaranteeing extended lifespan and suitability for high-traffic regions. Furthermore, aluminum can be effortlessly tailored and molded to meet specific design requirements, thereby offering limitless design possibilities. Additionally, the material is available in a plethora of finishes, including brushed, polished, or anodized options, which can significantly enhance the aesthetic allure of any interior space. Furthermore, aluminum emerges as a sustainable and eco-friendly alternative, given its easy recyclability and low carbon footprint relative to other materials. All in all, aluminum coils represent a pragmatic and visually pleasing choice for interior design applications.

- Q: How do aluminum coils contribute to energy-efficient lighting installations?

- Aluminum coils contribute to energy-efficient lighting installations by providing excellent thermal conductivity, which helps dissipate heat efficiently. This reduces the energy consumed by the lighting system and extends the lifespan of the bulbs. Additionally, aluminum coils are lightweight, durable, and corrosion-resistant, making them suitable for various lighting applications.

- Q: Explain how aluminum coils impact the manufacturing process.

- <p>Aluminum coils significantly affect the production process by offering versatility and efficiency. They are easily formed, cut, and shaped, which streamlines manufacturing. Their lightweight nature reduces the energy consumption in transportation and handling. Additionally, aluminum coils' corrosion resistance and durability reduce waste and the need for frequent replacements, enhancing sustainability. They also contribute to the production of various products, such as automotive parts, construction materials, and packaging, by providing a consistent and high-quality material.</p>

- Q: What are the legal frameworks or regulations that control the manufacturing and distribution of aluminum coil?

- <p>Yes, there are regulations and laws governing the production and sale of aluminum coil. These often include environmental protection laws that regulate emissions and waste disposal, safety standards for manufacturing processes, and quality control regulations to ensure the product meets certain specifications. Additionally, trade laws and tariffs may affect the sale of aluminum coil, especially when it crosses international borders. Compliance with these regulations is crucial to avoid penalties and maintain a competitive edge in the market.</p>

- Q: Should the aluminum roll be in the direction of the aluminum roll length or width?

- Grade two subgrade width is 10.0m. When setting up the slow lane, the width of the new standard subgrade is 15m and 12m respectively, while the original standard is 17.0m, corresponding lane 14.0m.Provincial standard is 20m, but must be hard shoulder, the corresponding pavement width of 10.5m, 8.5m.The highway bridge, a special highway, using integrated superstructure, median and shoulder width of appropriate narrow, but should not be less than the minimum value of the corresponding standard 28m subgrade, bridge deck width is 26m.

- Q: What precautions should be taken when handling aluminum coils to ensure safety?

- <p>When using aluminum coils, safety measures include wearing appropriate personal protective equipment such as gloves and safety glasses to prevent cuts and eye injuries. Ensure the work area is well-ventilated to avoid inhaling fumes from any processes involving the coils. Keep the coils dry to prevent electrical hazards. Use proper handling equipment to avoid back injuries from heavy loads. Always follow the manufacturer's guidelines for the specific aluminum coil products being used. Regularly inspect the coils for any signs of damage or wear that could lead to accidents.</p>

- Q: What does it mean to slice aluminum coil by decoiler machine?

- The operating procedures of decoiler machine: 1, Select appropriate aluminum coil according to production work order requirement to be processed, paying attention to the thickness, width and material of aluminum coil. 2, Put the aluminum coil into the coil loading car with traveling crane and inch the car into the uncoiler. The aluminum coil and decoiler machine should be in the same direction. Hold the aluminum coil down with leading head, and open the auxiliary bearing. 3, Turn on the shovel head, and inch the uncoiler to lead the aluminum sheet into the leveler. Adjust the leveler according to the thickness and width of aluminum sheet to ensure the flatness. 4, Turn on the front gap bridge and back gap bridge in control main platform, inch the leveler to lead aluminum sheet into re-leveler. Adjust the re-leveler to ensure the flatness of aluminum sheet. Put it into the shear gauge and plate shearer. 5, Take back the front and back gap bridge. Inch the plate shearer to cut off the sheet head and shear the aluminum sheet according to production work order. Check the first sheet to see whether it meets the quality standard and whether there is defect in flatness, length, diagonal, and surface of aluminum sheet. If it is qualified, turn on the conveyor. Put the aluminum sheet holder on the pallet. Adjust the pallet according to the width and length of aluminum sheet. Input quantity and length on the control main platform. Then turn on the auto control to produce automatically. The production process can be observed at any time. 6, If there is aluminum coil left, unwind, package and put it into storage in reverse steps.

- Q: Aluminum silicate felt fiber needle blanket noise reduction?

- Aluminum silicate needled blanket belongs to the porous material, porosity higher than ninety-six percent in noise reduction has an absolute advantage, because the aluminum silicate needled blanket belongs to soft products, the lack of stress in the industrial application, so there is no large-scale promotion, mainly used in the silencing device of heavy trucks, trucks and cars. And in the heat insulation, aluminum silicate needled blanket technology with a special one-time plastic molding, as the car chassis fireproof heat insulation layer, and now Xiamen Kinglong has reached a cooperation agreement.

- Q: Aluminum is directly below Mg. If aluminum is oxidized so readily, then how can we make planes or ships out of it and they don't fall apart after a few months or years?

- Yes aluminum does oxidize just like any other metal. The difference is that aluminum oxidizes the same color as the metal therefore you cannot tell that is oxidizing. Once is oxidizes a little bit, the oxidize protects the metal and it does not oxidize any more.

- Q: What are the different types of surface defects in aluminum coils?

- Aluminum coils can exhibit various surface defects, which can arise during manufacturing or as a result of handling and transportation. Common types of defects include scratches, pits, streaks, dents, oxidation, corrosion, and stains. Scratches are visible marks caused by contact with sharp objects and can range from superficial to deep grooves. Pits are small depressions caused by corrosion, wear and tear, or impurities in the aluminum material. Streaks are thin lines or bands caused by uneven coating application, improper cleaning, or contamination during manufacturing. Dents are deformations caused by impact or pressure during handling, stacking, or transportation. Oxidation refers to the formation of a thin layer of aluminum oxide on the surface, either naturally or due to exposure to moisture, air, or certain chemicals. Corrosion is the gradual deterioration of the surface due to chemical reactions with the environment, leading to discoloration, pitting, or the formation of powdery or flaky deposits. Stains are visible discolorations caused by water spots, oils, lubricants, or other contaminants. Manufacturers and suppliers implement quality control measures to minimize these defects and ensure that the coils meet the required standards and specifications. It is important to consider the severity and impact of these defects on the performance and appearance of the final product.

Send your message to us

1145 H19 Laminated Raw Aluminum Coil from China 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords