Ac Aluminum Coil White Color Painted Aluminum Foils for Insulated Ducts

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Color Painted Aluminium Foils Used for Insulated Ducts

We specialize in Blue Coated Aluminium Foils Used for Insulated Panels . Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Color Painted Aluminium Foils Used for Insulated Ducts

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

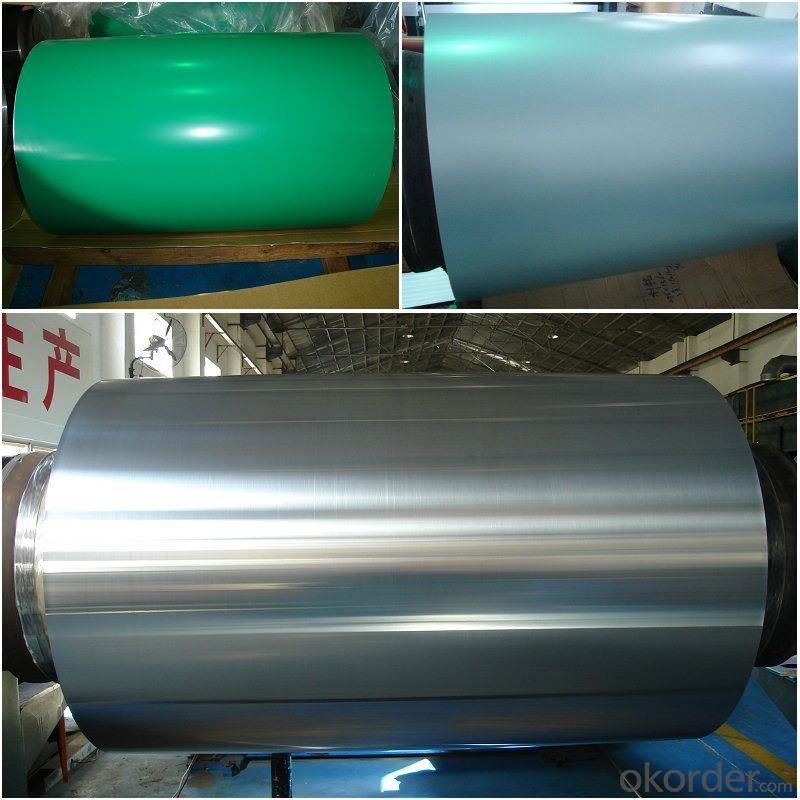

3. Color Painted Aluminium Foils Used for Insulated Ducts Images

4.Specification of Color Painted Aluminium Foils Used for Insulated Ducts

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are aluminum coils affected by magnetic fields?

- No, aluminum coils are not affected by magnetic fields as aluminum is not a magnetic material.

- Q: Can aluminum coils be customized in terms of thickness?

- Aluminum coils can indeed undergo customization in terms of thickness. The specific requirements of a particular application can determine the adjustment of aluminum coils' thickness. This customization is attained through the process of aluminum coil slitting, which involves cutting the original coil into narrower coils of the desired thickness. This method enables the flexibility to meet a range of needs and specifications across diverse industries.

- Q: Hey everybody I'm trying to improve the performance of my vintage metal Coleman cooler I just got. To test it I filled it up with water bottles and 5lbs of cubed ice from Stop and Shop and left it in the closet with the dorm's AC set to 65. When I got back 28 hours later the ice was completely melted. The water still kept the drinks cool for several days after that, but I'm frustrated that the ice melted in a single day.

- Aluminum foil has zero R factor (insulation factor). However, if it put on the outside of a cooler it will reflect the sun rays away from the cooler, and make it easier for your cooler to keep things cool. Gel packs are slightly better than extra ice (depending on the amount/concentration of glycol alcohol in them) -- gel packs are popular because they are self contained and not as wet and messy as melted ice. Edit: Well, indoors the aluminum would not be a complete waist. Heat waves from inside the house would still bounce off the aluminum. But the other answerer mentioned a very good way to further insulate your cooler. Just attach (tape or glue) stryrofoam sheets to the outside of your cooler == that would be a big time improvement.

- Q: This question is asking for a comparison of various types of aluminum coils, highlighting their unique characteristics and uses.

- <p>Aluminum coils are differentiated by their thickness, alloy composition, surface treatment, and temper. Common types include 1000 series coils with high purity, 3000 series known for formability, 5000 series for corrosion resistance, and 6000 series for strength. Thickness varies from thin gauges used in packaging to thick ones for construction. Surface treatments can include anodizing, painting, or lacquering for enhanced properties. Temper refers to the hardness and strength, with 'H' for hard and 'O' for soft tempers. Each type serves specific industries, such as automotive, aerospace, construction, and packaging.</p>

- Q: Hey! I have an Aluminum MacBook (2.4 GHz Core 2 Duo, 9400m graphics processor), and I'm wondering whether it's worth updating to the new 2011 13 MacBook Pro. I'm mainly looking for two things: 1. What would be the difference between the 2.4 GHz Core 2 Duo, and the 2.3 GHz i5, and 2. What would be the difference between the 9400m and the HD 3000 Graphics?Thanks! :)

- THIS ONE IS BEST ACCORDING TO YOUR REQUIREMENT Apple MacBook Pro MC700LL/A 13.3-Inch Laptop *13.3-inch LED-backlit glossy widescreen display with edge-to-edge, uninterrupted glass (1280 x 800-pixel resolution). *2.3 GHz Intel Core i5 dual-core processor (Sandy Bridge) with 3 MB shared L3 cache for excellent multitasking. *Intel HD Graphics 3000 with 384 MB of DDR3 SDRAM shared with main memory. *320 GB Serial ATA hard drive (5400 RPM) *4 GB installed RAM (1333 MHz DDR3; supports up to 8 GB) *8x slot-loading SuperDrive with double-layer DVD support (DVD±R DL/DVD±RW/CD-RW) *Built-in FaceTime HD camera for video chatting *Wi-Fi wireless networking (based on 802.11n specification; 802.11a/b/g compatible) *Gigabit Ethernet wired networking (10/100/1000) *Bluetooth 2.1 + EDR (Enhanced Data Rate) for connecting with peripherals such as keyboards, mice and cell phones *Two USB 2.0 ports, one FireWire 800 port *SDXC card slot *Thunderbolt port with native Mini DisplayPort output plus support for DVI, VGA, dual-link DVI, and HDMI (requires adapters, sold separately) *Multi-Touch trackpad for precise cursor control with support for inertial scrolling, pinch, rotate, swipe, three-finger swipe, four-finger swipe, tap, double-tap, and drag capabilities *Full-size backlit keyboard *Stereo speakers with subwoofers *Dimensions: 12.78 x 8.94 x 0.95 inches (WxDxH) *Weight: 4.5 pounds *Up to 7 hours of battery life *Meets Energy Star 5.0 requirements *Rated EPEAT Gold

- Q: How do aluminum coils perform in high-temperature applications?

- Aluminum coils excel in high-temperature scenarios due to their exceptional performance. Renowned for their superb heat conductivity and high melting point, aluminum coils can withstand extreme temperatures while maintaining their structural integrity. As a result, they are widely favored in various industries, such as automotive, aerospace, and HVAC systems, where heat transfer and dissipation are crucial. A key advantage of aluminum coils in high-temperature applications lies in their efficient heat transfer capabilities. Unlike commonly used metals like copper or steel, aluminum boasts significantly higher thermal conductivity. Consequently, aluminum coils swiftly and effectively transfer heat from one area to another, ensuring efficient heat dissipation and preventing overheating. Furthermore, aluminum possesses a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), surpassing that of many other metals. This notable attribute enables aluminum coils to endure high temperatures without distortion, warping, or compromising their structural integrity. Their stability in elevated temperatures renders them highly suitable for applications where heat resistance is essential, such as engine cooling systems or industrial ovens. Moreover, aluminum coils offer the advantage of being lightweight compared to other metals, making them even more beneficial in high-temperature environments. Their low density facilitates easier handling and installation, thereby reducing the overall weight of the system. This aspect is particularly valuable in industries like automotive and aerospace, where weight reduction plays a significant role in enhancing fuel efficiency and overall performance. In conclusion, aluminum coils are exceptionally dependable and prove to be highly efficient in high-temperature applications. Their outstanding heat conductivity, high melting point, and lightweight properties make them an ideal choice for industries that require effective heat transfer, dissipation, and resistance to heat.

- Q: This question asks for a comparison of the pros and cons of utilizing steel coils in construction projects.

- <p>Advantages of using steel coils in construction include their high strength and durability, which allows for the creation of robust structures. They are also resistant to corrosion and can withstand harsh weather conditions. Steel coils are versatile and can be easily shaped and welded, making them suitable for a variety of construction applications. Additionally, they are recyclable, contributing to sustainability efforts. Disadvantages include the initial high cost of steel coils compared to some other materials, and the potential for rust if not properly maintained. Steel structures may also require more frequent inspections and maintenance due to the risk of corrosion over time, especially in coastal or humid environments.</p>

- Q: I live around Minneapolis, MN. Is there a place that you can recycle crushed aluminum cans for money around here?

- Probably there are scrap metal companies in most major cities. It takes a lot of cans to make any money at it though .

- Q: Briefly describe the process of aluminum production from bauxite. Describe the electrolyte and write the anode and cathode half-reactions.

- Bauxite is purified by washing with sodium hydroxide and then seeding with dry ice. The purified aluminium oxide is then dissolved in molten cryolite at 900 degrees C (the electrolyte). It is electrolysed with grapite anodes and a graphite cathode that acts as the vessel for the reaction. Anode; 2 O2- - O2(g) + 4e Cathode: Al3+ + 3e - Al(l)

- Q: What are the electrical conductivity properties of aluminum coils?

- Aluminum coils exhibit excellent electrical conductivity properties. Aluminum is a highly conductive metal, ranking second only to copper in terms of electrical conductivity. The conductivity of aluminum is approximately 61% of copper's conductivity. This makes aluminum coils a popular choice for electrical applications where high conductivity is required. The electrical conductivity of aluminum is attributed to its atomic structure. Aluminum atoms have a relatively high number of free electrons, which are responsible for the flow of electric current. These free electrons can easily move through the lattice structure of aluminum, resulting in efficient electrical conduction. Furthermore, aluminum possesses low resistance, allowing for minimal energy loss during the transmission of electricity. This makes aluminum coils a cost-effective option for electrical wiring, power transmission lines, and other applications that require efficient electrical conductivity. It is worth noting that aluminum's electrical conductivity decreases slightly with increasing temperature. However, this decrease is relatively small compared to other metals, making aluminum coils a reliable choice for applications that involve high temperatures. In summary, aluminum coils possess excellent electrical conductivity properties, making them suitable for a wide range of electrical applications. Their high conductivity, low resistance, and cost-effectiveness contribute to their widespread use in various industries.

Send your message to us

Ac Aluminum Coil White Color Painted Aluminum Foils for Insulated Ducts

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords