Alu Stock, Casting Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

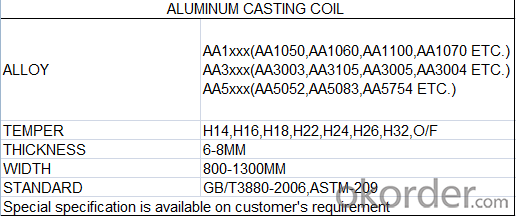

1.Structure of Alu Stock, Casting Coil Stock:

Alu Stock, Casting Coil Stock for thin coil and sheet is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Alu Stock, Casting Coil Stockis about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Alu Stock, Casting Coil Stock :

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Alu Stock, Casting Coil Stock

4. Production Process of Alu Stock, Casting Coil Stock

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Casting Coil

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: I want to separate the copper and aluminum so I will get more at the scrap yard for my radiators any one know of an easy way to do this? Thanks

- Does your scrapyard not have a good price for aluminum/copper radiators? Mine does. I Don't think you can separate them short of melting off the aluminum. The copper goes right through it. It would be a lot of work to separate them. Much more work than stripping copper wire. Before I take a load of scrap, I call all of the yards and get the best price. Sometimes this varies as much as $.50/pound on copper and radiators and brass and clean aluminum. Work with your phone, it will make you money. Last I checked, #1 copper 3.10/pound #2: 2.90, Radiators $1.50, Brass $1.40, Insulated copper wire $1.10 to $.90 Aluminum $.85 to $.55 dependingScrap Metal(steel). $9.00/100 Lets recycle Car batteries are $6 ea.

- Q: Are there any limitations on the surface treatment of aluminum coils?

- Yes, there are limitations on the surface treatment of aluminum coils. These limitations can vary depending on the specific surface treatment method being used. Factors such as the type of coating or finish being applied, the thickness of the coating, and the compatibility of the treatment with the aluminum alloy can all impose limitations on the surface treatment process. Additionally, environmental and regulatory considerations may also play a role in determining the allowable surface treatments for aluminum coils.

- Q: Can aluminum coils be used in the production of aluminum wire?

- Aluminum wire production can utilize aluminum coils as a starting material. To create aluminum wire, aluminum rods or bars are drawn or extruded through dies to decrease their diameter and increase their length. Aluminum coils, which are continuous rolls of aluminum sheet or strip, can serve as the initial material for this procedure. Initially, the aluminum coils are unwound and introduced into the wire production line for further processing. They undergo annealing, cleaning, and are then fed through a series of drawing dies to reduce their diameter and increase their length until the desired wire gauge is achieved. Consequently, aluminum coils prove to be an efficient and cost-effective starting material for aluminum wire production.

- Q: im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- why dont get wack each one over your head and see which hurts more. than you'll get your answer, just kidding. you should know metal is always harder than wood. but for baseball, you want a wooden bat, better for the swing, and the grip. I used to play little league back in the day and used aluminum bats, and even with batting gloves my hands were always killing me after the game.

- Q: What are the rules and regulations regarding the use of aluminum coil in commercial kitchen settings?

- <p>Yes, there are regulations on the use of aluminum coil in commercial kitchens. These regulations often relate to food safety, hygiene, and the material's suitability for contact with food. Aluminum is generally safe for food contact, but it must meet specific standards to ensure it does not leach harmful substances into food. Regulations may vary by country or region, with some areas having strict guidelines on the types of aluminum alloys allowed and their intended use. Compliance with these regulations is crucial to avoid health risks and legal penalties. It's important for commercial kitchens to use food-grade aluminum and to follow local health department guidelines.</p>

- Q: Is it possible to determine the spring constant of an aluminum coil using a spring compressor?

- <p>Yes, you can use a spring compressor to measure the spring constant of an aluminum coil. The spring constant (k) can be calculated using Hooke's Law, which states that the force exerted by a spring is proportional to its displacement (F = kx). By applying a known force to the spring and measuring the resulting displacement, you can calculate the spring constant. A spring compressor can apply a controlled force, and a displacement gauge can measure the compression, allowing you to determine the spring constant accurately.</p>

- Q: What are the different coil slitting methods for aluminum coils?

- There are several coil slitting methods for aluminum coils, including rotary shear slitting, loop slitting, and double knife slitting. Each method offers its own advantages and is suitable for different applications.

- Q: Are there any recycling programs for used aluminum coils?

- Yes, there are recycling programs available for used aluminum coils. Aluminum is highly recyclable and can be melted down and reused without losing its quality. Many recycling centers and scrap metal yards accept aluminum coils for recycling. Additionally, some HVAC (Heating, Ventilation, and Air Conditioning) companies have their own recycling programs for used aluminum coils, as they are commonly used in air conditioning systems. It is always recommended to check with your local recycling center or HVAC companies to inquire about specific recycling programs for used aluminum coils in your area.

- Q: where's the best place to look for aluminum not cans

- It depends on what you will use it for. If you are just looking for scrap aluminum to be melted down, cars radiators a full of aluminum. Otherwise, maybe check with a local metal fabricator and see if you could buy some of their drop.

- Q: What types of aluminum coil are best suited for specific applications?

- <p>Yes, different types of aluminum coil are better suited for specific applications. For instance, 1100 series aluminum coil, known for its high purity and excellent formability, is ideal for applications requiring deep drawing or bending. The 3003 series is often used for applications needing good corrosion resistance and formability, such as automotive parts and chemical equipment. The 5052 series offers a balance of strength and corrosion resistance, making it suitable for marine applications and aircraft structures. The 6061 series is known for its strength and is often used in construction and transportation industries. Each series has unique properties that make it more suitable for certain applications, so selection should be based on the specific requirements of the project.</p>

Send your message to us

Alu Stock, Casting Coil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords