Black Aluminum Coil Stock for Color Coated Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil for Curtain Walls

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coated Aluminum Coil for Curtain Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil for Curtain Walls

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

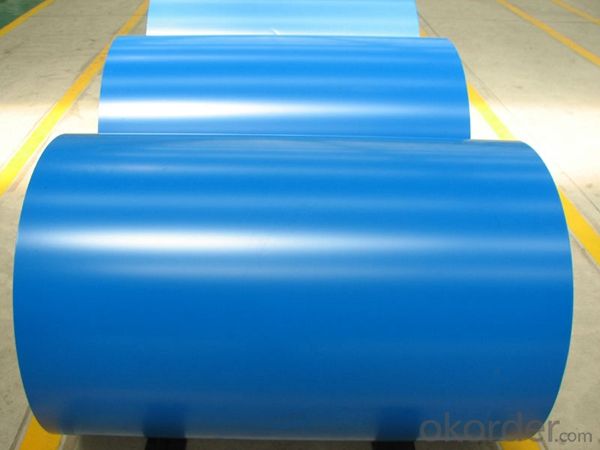

5. Image of Color Coated Aluminum Coil for Curtain Walls

6. Package and shipping of Color Coated Aluminum Coil for Curtain Walls

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. The disposal of aluminum coil waste is subject to various environmental regulations to ensure proper handling and prevent any potential harm to the environment and human health. One of the key regulations is the Resource Conservation and Recovery Act (RCRA) in the United States. Under this act, aluminum coil waste is considered a hazardous waste if it exhibits certain characteristics such as ignitability, corrosivity, reactivity, or toxicity. If the waste meets these criteria, it must be managed as hazardous waste and disposed of in accordance with RCRA regulations. This may involve treatment, storage, and disposal at an approved hazardous waste facility. Additionally, the Environmental Protection Agency (EPA) has established guidelines for the disposal of non-hazardous aluminum coil waste. These guidelines typically require proper storage, labeling, and transportation of the waste to an authorized disposal facility. The disposal facility should be equipped to handle and process the waste in an environmentally responsible manner. In many countries, including the United States, local, state, and federal regulations may also apply to the disposal of aluminum coil waste. These regulations may vary depending on the specific location and the nature of the waste. It is crucial for businesses and individuals involved in the disposal of aluminum coil waste to familiarize themselves with the applicable regulations to ensure compliance and avoid potential penalties. Overall, it is important to follow the specific regulations for the disposal of aluminum coil waste to protect the environment, prevent pollution, and ensure the safety of individuals involved in waste management.

- Q: How do aluminum coils perform in extreme temperature conditions?

- Aluminum coils generally perform well in extreme temperature conditions due to their high thermal conductivity and low thermal expansion. They can efficiently transfer heat and are resistant to warping or cracking, making them suitable for various applications in extreme temperatures.

- Q: How do aluminum coils contribute to energy savings in buildings?

- Aluminum coils play a vital role in HVAC systems for buildings, helping to save energy. To start, aluminum coils are highly effective at transferring heat. HVAC systems use these coils to facilitate the exchange of heat between indoor and outdoor environments. Aluminum's thermal conductivity allows for fast and efficient heat transfer, resulting in less energy needed to heat or cool a space. This means that HVAC systems equipped with aluminum coils can achieve the desired indoor temperature more efficiently, leading to energy savings. Furthermore, aluminum coils are lightweight and have excellent corrosion resistance. This property ensures the longevity and durability of the HVAC system, reducing the need for frequent replacements. By lasting longer, the energy and resources used in manufacturing new coils are saved, resulting in reduced energy consumption and environmental impact. Moreover, aluminum coils are highly recyclable. When an HVAC system reaches the end of its life cycle, the aluminum coils can be easily recycled and repurposed. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials. By promoting recycling, energy is conserved, and greenhouse gas emissions are reduced. Additionally, aluminum's reflective properties contribute to energy savings in buildings. When used in HVAC systems, aluminum coils can reflect and deflect sunlight, reducing the amount of heat absorbed by the building. This reduces the workload on the HVAC system, resulting in lower energy consumption and increased energy efficiency. In conclusion, the use of aluminum coils in HVAC systems brings about energy savings in buildings due to their high thermal conductivity, lightweight and durable nature, recyclability, and reflective properties. By adopting aluminum coils, buildings can achieve optimal temperature control with reduced energy consumption, leading to significant energy savings and a more sustainable environment.

- Q: is Aluminum wrotten with a 2 behnd it?

- Aluminum is not a diatomic atom, which is to say, in it's equilibrium state it has only one atom, written Al. As an ion, aluminum has a charge of 3+, and may have a subscript of 2 when written in an ionic formula (i.e., aluminum oxide: Al2O3).

- Q: How are aluminum coils used in the packaging industry?

- Aluminum coils play a vital role in the packaging industry due to their excellent properties and versatility. These coils are used extensively in the packaging industry to create a wide variety of packaging materials. One of the primary uses of aluminum coils in the packaging industry is in the production of aluminum foil. Aluminum foil is a thin sheet of aluminum that is used for various packaging applications. It is flexible, lightweight, and has excellent barrier properties, making it ideal for preserving the freshness, taste, and quality of food products. Aluminum foil is commonly used for wrapping food items such as sandwiches, snacks, and leftovers. It is also used for packaging pharmaceutical products, cosmetics, and other consumer goods. Furthermore, aluminum coils are used to create aluminum cans, which are widely used for packaging beverages, such as soda, beer, and energy drinks. Aluminum cans are lightweight, durable, and provide excellent protection against light, oxygen, and moisture. They also have a longer shelf life compared to other packaging materials, ensuring the preservation of the product's taste and quality. In addition to aluminum foil and cans, aluminum coils are used in the production of blister packs, which are commonly used in the pharmaceutical industry. Blister packs consist of a plastic sheet with individual compartments that hold medications or capsules. The aluminum coil is laminated onto the plastic sheet, providing a barrier against light, moisture, and oxygen, ensuring the stability and integrity of the medications. Moreover, aluminum coils are utilized in the production of flexible packaging materials, such as pouches, sachets, and bags. These packaging materials are widely used for various products, including snacks, pet food, coffee, and personal care items. Aluminum coils are laminated onto plastic films to create a barrier against moisture, oxygen, and light, thereby extending the shelf life of the packaged products. Overall, aluminum coils are indispensable in the packaging industry, offering an array of benefits such as lightweight, durability, barrier properties, and versatility. From aluminum foil to cans, blister packs to flexible packaging materials, these coils are vital in preserving the freshness, taste, and quality of various products.

- Q: What are the different types of protective coatings for aluminum coils?

- Aluminum coils can benefit from various protective coatings to boost their durability and lifespan while safeguarding against environmental elements. 1. Polyester Coatings: With their exceptional UV ray and weather resistance, polyester coatings are widely utilized for aluminum coils. They offer vibrant color retention and a broad spectrum of color options, making them ideal for applications where aesthetics matter, such as in architecture. 2. Polyvinylidene Fluoride (PVDF) Coatings: Renowned for their exceptional resistance against fading, chalking, and chemical exposure, PVDF coatings are suitable for harsh environments. They exhibit high weatherability and can withstand extreme temperatures, making them commonly used in industrial and commercial settings. 3. Epoxy Coatings: Epoxy coatings present robust adhesion and excellent corrosion resistance. They act as a protective barrier against moisture and chemicals, making them well-suited for applications where the coils may encounter harsh conditions, particularly in marine and industrial settings. 4. Acrylic Coatings: Acrylic coatings offer good adhesion and flexibility. They provide moderate weather resistance and can be easily applied and repaired. Acrylic coatings find applications in various sectors, including automotive and general industrial uses. 5. Polyurethane Coatings: Polyurethane coatings showcase outstanding resistance to abrasion, chemicals, and weathering. They offer exceptional durability and are commonly employed in demanding applications where the coils may face harsh conditions or heavy wear. 6. Silicone Coatings: Silicone coatings boast remarkable resistance to extreme temperatures and UV exposure. They exhibit excellent weatherability and can endure prolonged exposure to sunlight without degradation. Silicone coatings are frequently utilized in automotive parts and outdoor equipment. The selection of the appropriate protective coating should be based on the specific requirements of the aluminum coils and the intended application. Factors to consider include the desired level of protection, appearance, and the environmental conditions to which the coils will be exposed.

- Q: How are aluminum coils typically stored and transported?

- Aluminum coils are typically stored and transported in a way that ensures their protection and prevents any damage. They are usually stored in a warehouse or storage facility where they are kept in a vertical position. This vertical storage helps to prevent any bending or warping of the coils. When it comes to transportation, aluminum coils are often transported using specialized coil trailers or flatbed trucks. These trailers are designed to securely hold the coils in place during transit. The coils are typically secured using straps or bands to prevent any movement or shifting while on the road. Additionally, it is common for aluminum coils to be wrapped in protective materials such as plastic or cardboard to provide an extra layer of protection against moisture, dirt, and other potential hazards during transportation. It is important to handle aluminum coils with care to avoid any damage, as even small dents or scratches can affect their performance. Therefore, proper storage and transport methods are crucial to ensure that the coils arrive at their destination in optimal condition.

- Q: I think the use of aluminum, at the lower levels, has really hurt US born players. To give a kid a piece of metal, and expect him to use wood when drafted........ I think US should go back to wood, whatever the costs (I know the aluminum is far cheaper). Thoughts....Cheers.

- You nailed it my friend. Aluminum has given our players a false sense of themselves and what they think they can do as a hitter. At the same time it is ruining the young pitchers when it comes to confidence. I have thought for years that it's destroying the game from within. Wood has always been the way to go. I would much rather hear the crack of the bat instead of the ping of the bat any day. Finally let's not forget the danger of aluminum bats. A line drive back to the mound comes off metal a lot faster than with wood. Pitchers are in harms way every time they throw a pitch!

- Q: What are the environmental benefits of using aluminum coils?

- The environmental benefits of using aluminum coils include their high recyclability, low carbon footprint, and energy efficiency. Aluminum is one of the most recycled materials in the world, reducing the need for mining and extraction of new raw materials. Recycling aluminum coils requires significantly less energy compared to making new ones from scratch, resulting in reduced greenhouse gas emissions. Additionally, aluminum coils have excellent heat transfer properties, enabling more efficient cooling and heating systems, which ultimately reduce energy consumption and contribute to a greener environment.

- Q: How do aluminum coils compare to stainless steel coils in terms of durability?

- Aluminum coils are generally less durable than stainless steel coils. While aluminum coils are lightweight and corrosion-resistant, they are prone to denting and are not as strong as stainless steel. On the other hand, stainless steel coils are highly durable, resistant to dents, and have a longer lifespan.

Send your message to us

Black Aluminum Coil Stock for Color Coated Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords