Ac Aluminum Coil White - Aluminum Coil/Aluminum Circle/Aluminum Sheet Famous Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Circle

1) Alloy | AA1050, AA1060, AA1100, AA1235, AA1070, AA3104, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011etc |

2) Temper | O/H12/H14/H16/H18/H32/H34/H36/H38//H22/H24/H26/H28/T6/T651/T3/T351 etc |

3) Thickness | 0.2mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | AluminIum |

7) Coil Inner diameter | 76mm, 152mm or as required |

2. Application of Aluminum Circle

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors.

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Circle

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

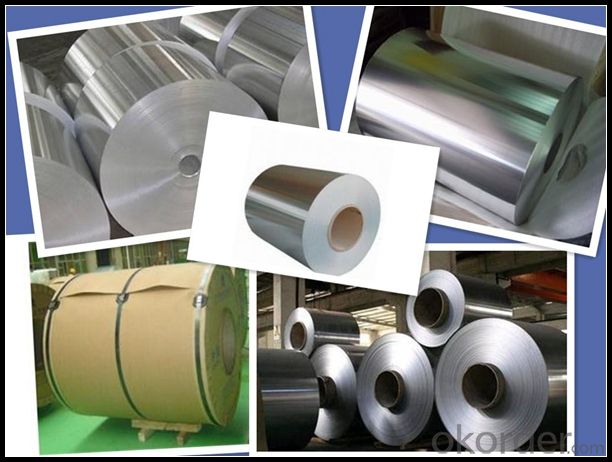

5. Image of Aluminum Circle

6. Package and shipping of

eye to wall

eye to the wall with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 30 to 35 days

2)What is the QC system:

We have QC staffs of 20 person and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) Where is your mainly market?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Would an SS scribe scratch an aluminum plate? What is the hardness value of both metals?

- the fast answer is for particular, the two could be welded with gas. the guy who suggested stainless no and aluminium particular is off the mark. Stainless is greater straightforward to weld with gas as aluminium has a quicker droop than stainless. droop is while it starts off to soften, and could become liquid. Aluminum will droop very rapidly, and in case you're no longer careful, will run off, or drip and you will might desire to enable it cool. With practice you will know while it quite is approximately to droop, and adjust how lots warmth you're including. you additionally can cool the puddle via including filler( welding rod). endure in concepts although, you may in basic terms weld comparable metals, and could use an identical kind of welding rod by way of fact the metallic you're welding. Stainless will start to puddle, and it quite is particularly obtrusive that it quite is transforming into liquid, so which you would be able to upload filler and notice that the weld is progressing. My single superb piece of suggestion is to learn welding, and if available, get somebody to tutor you strategies. a community highschool might have a unfastened or very low priced direction on welding. discovering on your guy or woman is obtainable, yet no longer something beats sturdy suggestion. you will get lots greater suited effects, and not have almost the disappointment.

- Q: Are there any limitations to using aluminum coils?

- Using aluminum coils comes with several limitations. Firstly, their cost is higher compared to other materials like copper, which can be a constraint for those with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means they are less efficient at transferring heat, resulting in decreased performance in some applications. In addition, aluminum is more prone to corrosion and oxidation than other materials. This limitation is particularly relevant in highly corrosive environments, like coastal areas or industrial settings. Moreover, aluminum coils are generally unsuitable for high-pressure applications. They are more likely to experience leaks or failures under high pressure, which restricts their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are less malleable than copper coils, making them more challenging to handle during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, although aluminum coils have advantages like being lightweight and environmentally friendly, their limitations must be carefully considered based on the specific application and requirements.

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- Well using aluminum heads would be enough to justify doing it because i have aluminum heads and im at 11:1 compression. These heads are 9.5:1 compression with 11:1 compression with twin turbos. Now you are running with straight motor and shoud be fine. Now if you are going to get that pony a supercharger I would suggest getting cast iron heads with a chrome finish to manage this power gain. I have had these for about 40K miles and are still fine. I will eventually change to cast iron with a chrome finish. Hope this helps.

- Q: What is the typical fatigue strength of aluminum coils?

- The fatigue strength of aluminum coils can vary depending on several factors, such as the alloy composition, heat treatment, manufacturing process, and the specific application. However, compared to other metals like steel, aluminum is generally known to have relatively low fatigue strength. Typically, the fatigue strength of aluminum coils falls within the range of 30% to 50% of their ultimate tensile strength (UTS). This means that the fatigue limit or endurance limit of aluminum coils is usually less than half of their maximum strength. It is worth noting that factors such as surface defects, stress concentrations, and environmental conditions like temperature and humidity can also affect the fatigue strength of aluminum coils. These factors can further decrease the fatigue strength of aluminum coils. Hence, when designing and using aluminum coils in applications where fatigue is a concern, it is crucial to consider the specific alloy and processing conditions. Additionally, implementing suitable design practices and maintenance procedures is vital to mitigate the risk of fatigue failure.

- Q: Can aluminum coils be used in high-altitude environments?

- Yes, aluminum coils can be used in high-altitude environments. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various applications, including in high-altitude environments. Aluminum coils are commonly used in air conditioning systems, heat exchangers, and refrigeration units, which can function efficiently at high altitudes. Aluminum's high strength-to-weight ratio allows it to withstand the extreme conditions found at high altitudes, including low temperatures, high winds, and low atmospheric pressure. Additionally, aluminum is non-magnetic, which is advantageous in certain high-altitude applications, such as aerospace and satellite technologies. Furthermore, aluminum has excellent thermal conductivity, allowing it to efficiently transfer heat, making it ideal for use in cooling systems operating in high-altitude environments. Its corrosion resistance properties also make it durable and able to withstand the effects of moisture, which can be prevalent in such environments. Overall, aluminum coils are a reliable and suitable choice for use in high-altitude environments due to their lightweight, corrosion resistance, thermal conductivity, and strength.

- Q: What are the different coil pattern options for aluminum coils?

- There are several different coil pattern options available for aluminum coils, depending on the specific application and desired aesthetic. Some common coil pattern options include: 1. Stucco Pattern: This pattern features a textured, raised surface that resembles the appearance of stucco. It provides increased durability and a non-slip surface, making it suitable for applications such as flooring or outdoor surfaces. 2. Diamond Pattern: This pattern consists of small diamond-shaped embossed designs, providing a visually appealing and slip-resistant surface. It is commonly used in applications such as stair treads, walkways, and decorative panels. 3. Wood Grain Pattern: This pattern replicates the appearance of natural wood grain, making it an attractive option for various architectural and interior design purposes. It is often used in applications such as wall cladding, ceiling panels, and furniture. 4. Checkered Pattern: Also known as the checker plate pattern, it features a grid of raised diamonds or squares. This pattern offers excellent slip resistance and is commonly used in applications where safety is a priority, such as ramps, industrial flooring, and staircases. 5. Plain Smooth Pattern: This pattern has a smooth, flat surface without any embossed designs or patterns. It is a versatile option suitable for a wide range of applications, including roofing, gutters, and general fabrication. 6. Ribbed Pattern: This pattern consists of parallel lines or ribs running along the length of the coil. It provides added strength and rigidity, making it commonly used in applications such as truck bodies, trailers, and industrial equipment. These are just a few examples of the various coil pattern options available for aluminum coils. The choice of pattern ultimately depends on the specific requirements of the project, such as functionality, durability, and aesthetic preferences.

- Q: I am looking for a place where I can have my aluminium channels anodized in Erode.

- KSR Agency Products Services Aluminum AnodisingAluminum ExtrusionsArchitectural GlassesBus BarComposite Panels Elevation Glass FittingsFalse CeilingHeat Sink Sections About Us KSR Agency is well-known, veteran-owned business enterprise. Our company is a promising manufacturer and supplier of wide range of Aluminum Extrusion channels and Anodizing Aluminum that includes the following products o Glass Fittings for Elevation o Bus Bars o Heat Sink Sections o Aluminum Extrusions o Architectural Glasses o False ceiling o Partitions o Composite Panels Our Anodizing methodologies: o Type I - Chromic Acid Anodize o Type II - Sulphuric Acid Anodize o Type III - Hard Anodize o Class 1 - Non-dyed o Class 2 - Dyed Our range of products has huge demand and widely accepted by many people all across for their outstanding features and are available in various patterns, designs, sizes, shapes. We use the best grade raw material and advanced methods of production in the process of manufacturing these products. Our products meet the international standards in quality that assures excellent performance in usage and customized as per the clients' specification and necessity. We deliver the orders within a stipulated time frame. Contact Details KSR Agency No. 45, Mudali Thottam, Bharathi Nagar, Sulai, Chittode Road, Erode - 638004, Tamil Nadu, India Mr. Sendhil Kumar +(91)-9739956109 Mr. Rajendran +(91)-9842876614

- Q: How to remove the fingerprint and glue residue on the color aluminum coil?

- Try to use essential balm. We often use the essential balm to remove glue residue on the stainless steel bowl and basin.

- Q: How are aluminum coils shipped and transported?

- Aluminum coils tend to be shipped and transported in various ways, depending on factors like size, weight, and destination. Below are a few common techniques: 1. Utilizing flatbed trucks: Flatbed trucks are frequently employed when shipping smaller aluminum coils for shorter distances. These coils are securely loaded onto the flatbed and fastened with straps or chains to prevent any movement during transportation. 2. Opting for intermodal containers: When shipping aluminum coils over longer distances, intermodal containers are a popular choice. These containers can be loaded onto trucks, trains, or ships, providing versatility. The coils are typically stacked and secured within the container using bracing or blocking materials to avoid any shifting. 3. Employing rail transport: Rail transport is also an option for transporting aluminum coils, particularly over longer distances. Coils are loaded onto flatcars or specialized coil cars that have built-in cradles or bolsters to securely hold the coils in place during transit. 4. Utilizing vessels: For international or distant shipments of aluminum coils, sea transport via cargo vessels is often used. Coils are carefully loaded into the cargo hold of the vessel and secured with lashings or other methods to prevent any movement or damage during the voyage. Regardless of the chosen transportation method, it is crucial to ensure that the aluminum coils are adequately protected from moisture, dust, and other potential sources of damage during transit. Packaging materials like moisture-resistant wrapping, protective covers, or crates are employed to safeguard the coils and maintain their quality until they reach their destination.

- Q: How are aluminum coils used in the electrical industry?

- Aluminum coils are widely used in the electrical industry for various applications such as transformers, motors, generators, and electrical transmission systems. These coils are used to create electromagnetic fields, which are essential for the functioning of these electrical devices. Additionally, aluminum coils are preferred due to their lightweight, high thermal conductivity, and cost-effectiveness compared to other materials.

Send your message to us

Ac Aluminum Coil White - Aluminum Coil/Aluminum Circle/Aluminum Sheet Famous Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords