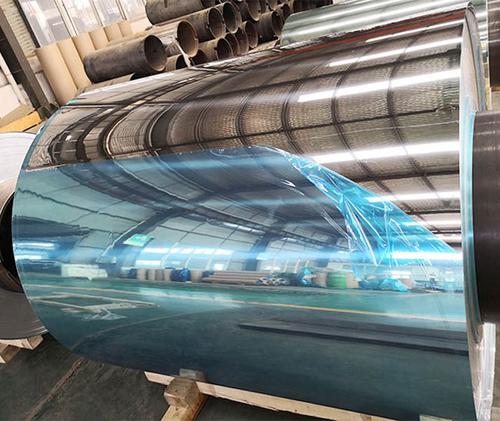

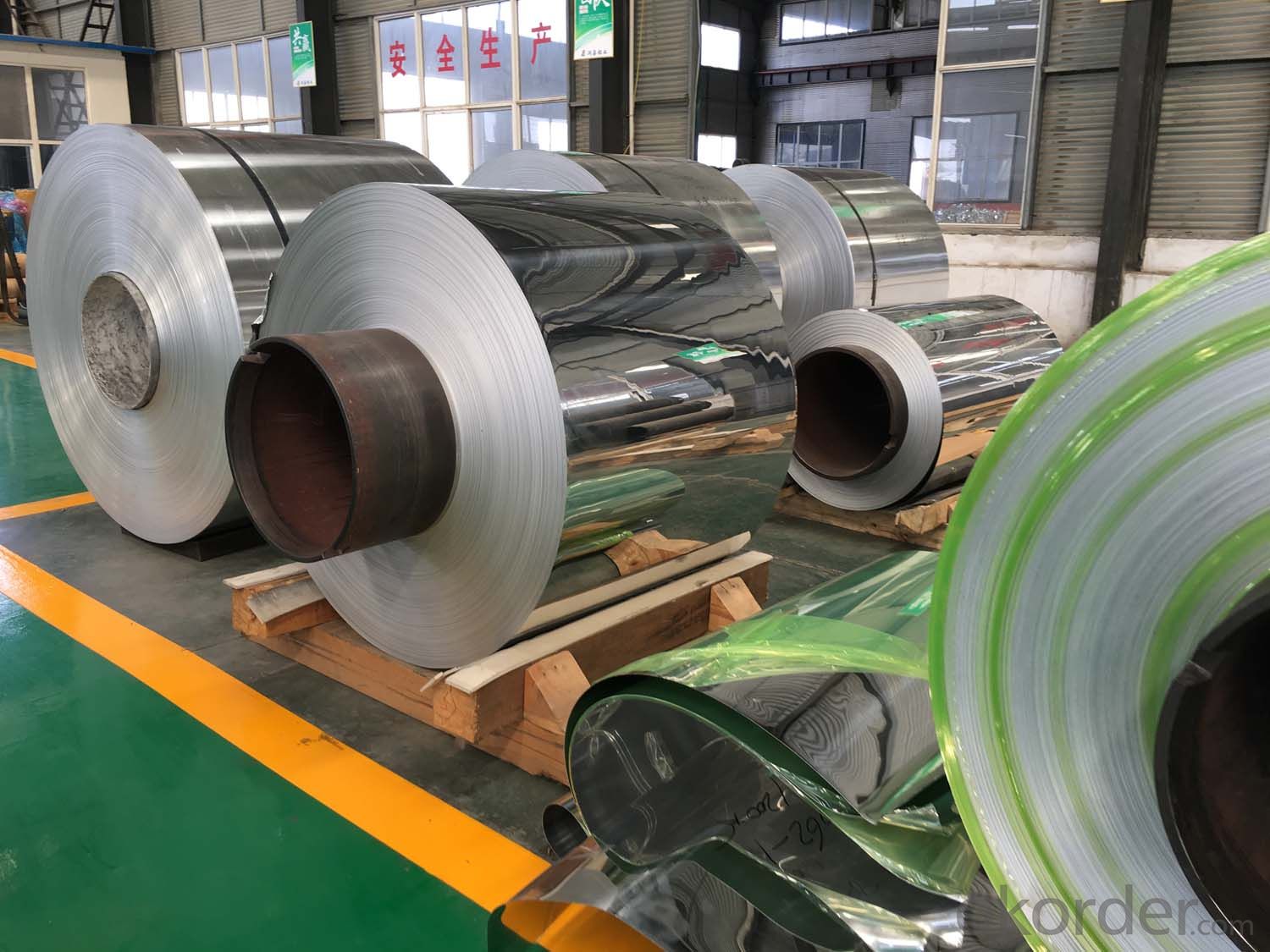

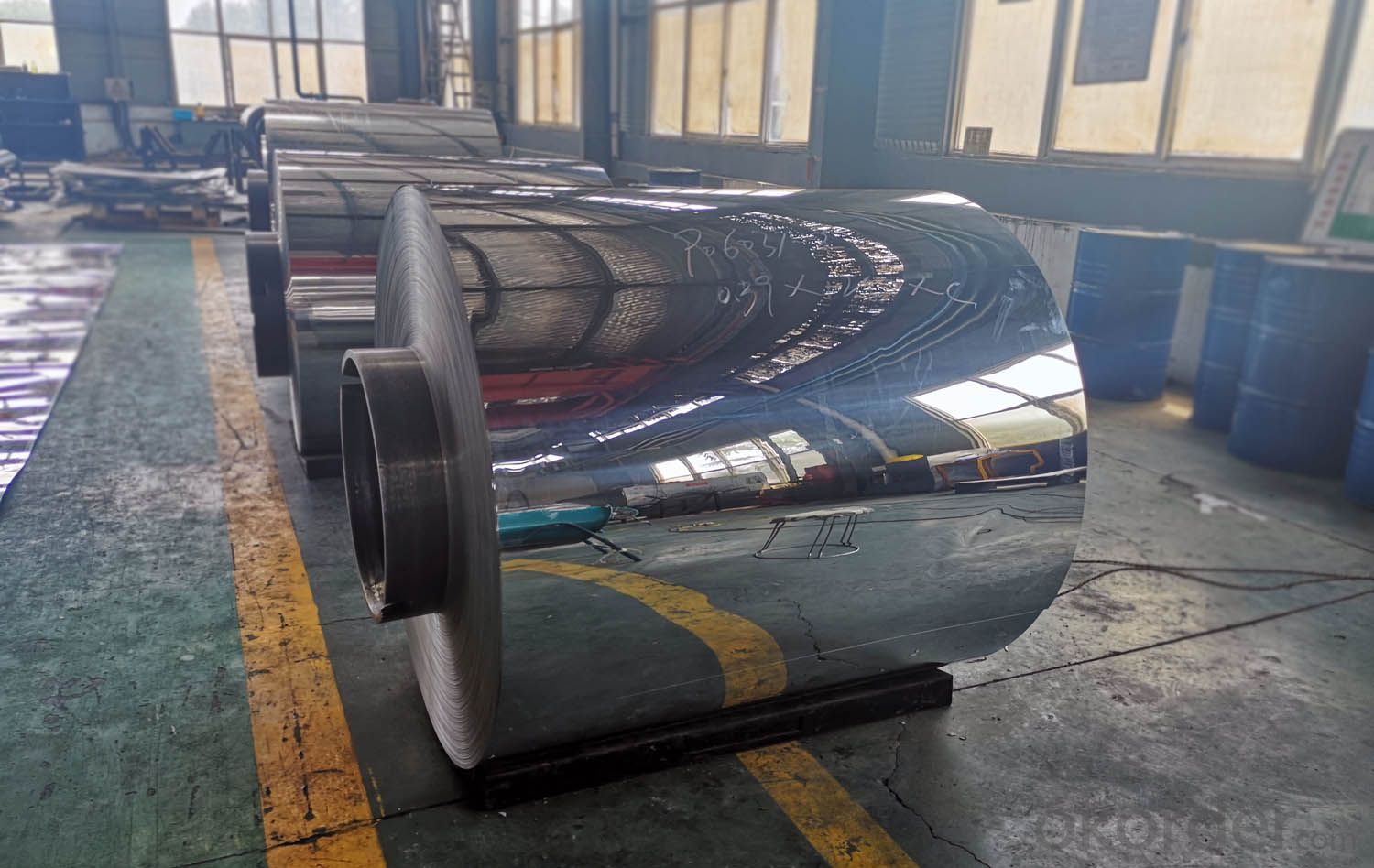

Polished aluminum mirror coil for sale 1050 1100 3003 5052 high brightness mirror aluminum coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High brightness mirror aluminum coil is a kind of aluminum alloy material treated by special process, with high reflectivity and glossiness on the surface, similar to the effect of mirror. Mirror aluminum coil is more suitable for lamp decoration and electrical panel than ordinary aluminum coil. It is widely used in architectural decoration, lighting equipment, electronic product housing, home appliance manufacturing and decorative parts of transportation vehiHigh brightness mirror aluminum coil is a kind of aluminum alloy material treated by special process, with high reflectivity and glossiness on the surface, similar to the effect of mirror. Mirror aluminum coil is more suitable for lamp decoration and electrical panel than ordinary aluminum coil. It is widely used in architectural decoration, lighting equipment, electronic product housing, home appliance manufacturing and decorative parts of transportation vehicles.

Mirror aluminum coil specifications:

| Alloy | 1050, 1060, 1070, 1085, 1100, 3003, 5052, etc |

| Temper | O - H112 |

| Thickness | 0.1-2.0mm |

| Width | 100-1600mm |

| Length | 100-16000mm |

| Reflectivity | 86 - 93% |

| Color | Silver or RAL color |

| Surface protection | PE/Plastic film covering |

| Application | ACP, lamp, decoration, solar reflector, etc. |

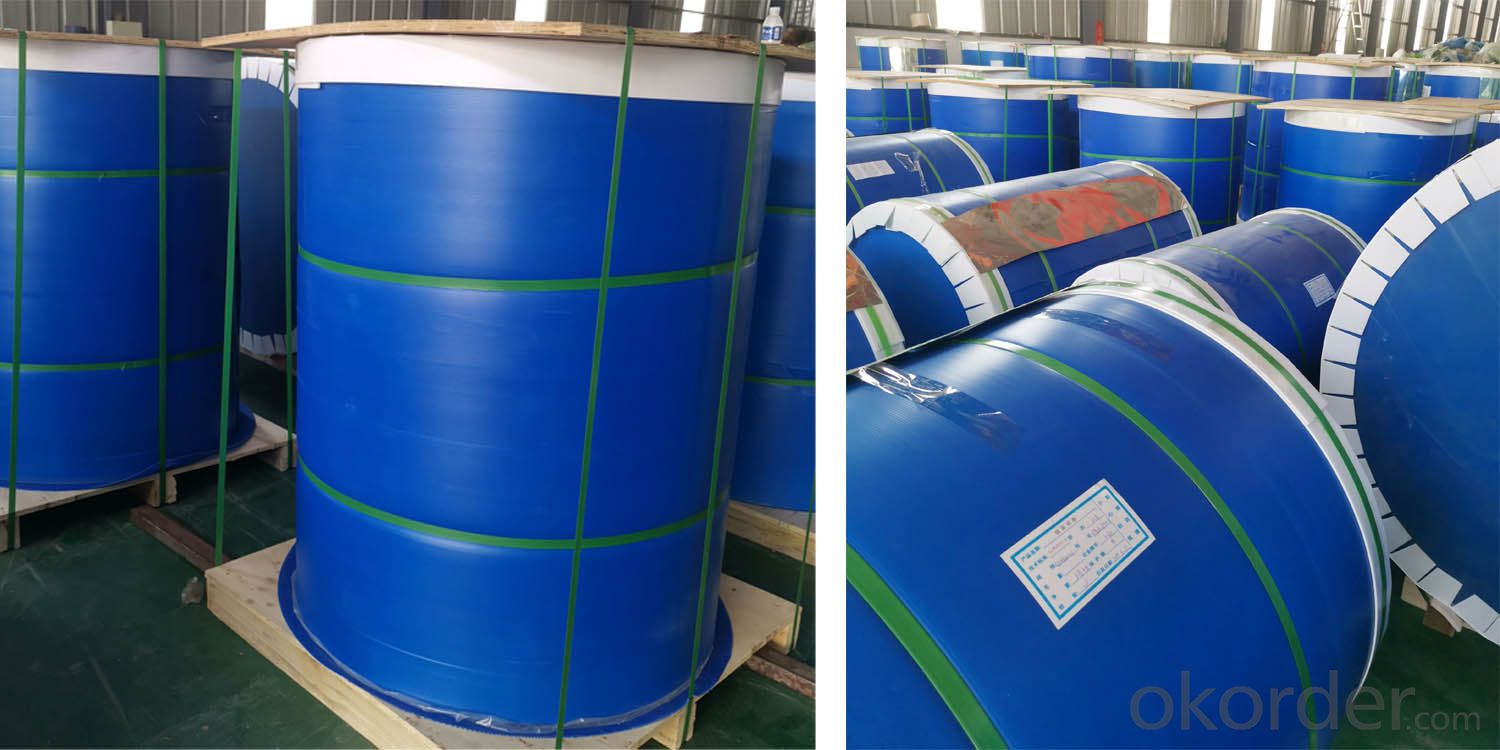

| Packaging | Standard seaworthy export carton. Wooden pallet. Waterproof paper and plastic kraft paper covering. Or as per customer requirements. |

Features:

1. High reflectivity: The surface of mirror aluminum coil can reflect a lot of light, suitable for lamp reflector and solar collector.

2. Good processing performance: It can be processed into various shapes by cutting, stamping, bending, etc.

3. Corrosion resistance: After the surface is oxidized, it has strong corrosion resistance and is suitable for long-term use.

4. Light weight: Aluminum has low density, which reduces the weight of the finished product.

5. Environmental protection: It can be recycled and conforms to the concept of green environmental protection.

Application areas:

1. Lighting reflective materials: such as reflectors and light guide plates of lamps.

2. Architectural decoration: used for wall and ceiling decoration and indoor and outdoor decoration.

3. Home appliance industry: such as decorative parts of TV, refrigerator panels and other electrical appliances.

4. Automobiles and vehicles: used for interior decoration, dashboards and headlight reflectors.

5. Solar energy equipment: as a light reflective material to improve the utilization rate of light energy.

FAQ:

Q1: How can I get a quote from you?

A1: You can leave us a message and we will reply in time.

Q2: Can I visit the factory?

A2: Of course. We warmly welcome you to visit our factory.

Q3: Can I get samples before ordering?

A3: Of course, free samples can be provided, the shipping fee needs to be paid by the buyer, and the postage will be returned after placing the order.

Q4: Do you accept third-party inspection?

A4: Yes, we definitely can accept inspection.

- Q: How are aluminum coils used in the production of sporting goods?

- Aluminum coils are used in the production of sporting goods primarily for their lightweight and durable properties. They are commonly used in the manufacturing of sports equipment such as baseball bats, tennis rackets, and bicycles. The coils are shaped, formed, and molded into the desired product, providing strength and flexibility while reducing overall weight. This allows athletes to have better control, enhanced performance, and reduced fatigue during sports activities.

- Q: Can aluminum coils be used for architectural applications?

- Yes, aluminum coils can be used for architectural applications. Aluminum is a versatile and lightweight material that is commonly used in construction due to its durability, corrosion resistance, and ease of installation. It can be formed into coils and used for various architectural elements such as roofing, cladding, facades, gutters, and window frames.

- Q: How do aluminum coils contribute to energy-efficient appliances?

- Enhancing the energy efficiency of appliances is a key role played by aluminum coils. The utilization of aluminum in the form of coils enables efficient transfer of heat, which is vital for appliances that require cooling or heating mechanisms. To begin with, the thermal conductivity of aluminum coils is exceptional. This implies that they can rapidly absorb and dissipate heat, resulting in more efficient cooling or heating procedures. This is particularly significant in appliances like refrigerators, air conditioners, and heat pumps, where effective heat transfer is crucial for maintaining the desired temperature. In addition, aluminum coils are lightweight yet durable, making them an ideal option for energy-efficient appliances. The lightweight nature of aluminum reduces the overall weight of the appliance, leading to lower energy consumption during transportation and installation. Furthermore, the durability of aluminum ensures a longer lifespan for the appliance, reducing the need for frequent maintenance or replacement. Furthermore, aluminum exhibits high resistance to corrosion, a common issue in appliances that come into contact with water or moisture. By incorporating aluminum coils, manufacturers can ensure the longevity and reliability of the appliance, thereby contributing to energy efficiency by minimizing the need for repairs or replacements. Lastly, aluminum is a highly recyclable material. The use of aluminum coils in appliances promotes sustainability and reduces the environmental impact. By opting for energy-efficient appliances that integrate aluminum coils, consumers can support the circular economy and contribute to a more sustainable future. In conclusion, aluminum coils significantly contribute to the energy efficiency of appliances. Their exceptional thermal conductivity, lightweight yet durable nature, corrosion resistance, and recyclability make them an ideal choice for enhancing the performance and sustainability of energy-efficient appliances.

- Q: How to use aluminum sheet to roll a 12m-long aluminum coil with a diameter of 184cm?

- According to project experience, first you should check the specification of the aluminum sheet and then design crafts such as connection method, installation and transportation according to equipment.

- Q: How are aluminum coils transported and delivered?

- Aluminum coils are typically transported and delivered using specialized transport vehicles equipped with coil racks or cradles that securely hold the coils in place. These vehicles can be trucks, trains, or ships, depending on the distance and mode of transportation. The coils are usually loaded onto the transport vehicle using cranes or forklifts, ensuring proper handling and minimizing damage. Once at the delivery destination, the coils are carefully unloaded using similar equipment and delivered to their final destination, such as a manufacturing facility or warehouse.

- Q: I know that Aluminum is a metal, and it's corrosive, but I've been wondering about how Aluminum Foil is created. Is it the same as the metal? Just pounded down? or is it a mixture of different elements?

- It is made by rolling an aluminum block thinner and thinner. Metal foil, such as tin foil had been around for years. The first plant designed for rolling aluminum foil was opened in 1910. NASA was not in existence then. It appears the inventor was: Hans Christian Oersted Year Invented: 1825 P.S. Aluminum is not corrosive. corrosive means it corrodes other things (as acid would). It does corrode. It is also the most reactive metal. It is oxidized immediately upon exposure to air - why it is difficult to solder. The aluminum oxide is not whetted by solder. Aluminum oxide is a ceramic, called Alumina. Anodized aluminum has has a thick layer of aluminum oxide formed on its surface

- Q: This question asks for a brief explanation of the process involved in the manufacturing of aluminum coils.

- <p>Aluminum coil is made through a series of processes starting with the melting of aluminum ingots or scrap. The molten aluminum is then poured into a casting machine where it's cooled and solidified into large slabs. These slabs are then heated and passed through a series of rolling mills to reduce their thickness and achieve the desired coil gauge. The rolling process is often hot or cold, depending on the final application of the coil. After rolling, the aluminum is coiled into rolls and may undergo additional treatments like annealing to improve its properties. Finally, the aluminum coil is cleaned, inspected, and shipped for use in various industries such as construction, automotive, and packaging.</p>

- Q: What are the density and specific gravity values of aluminum coils?

- The density of aluminum coils is approximately 2.7 g/cm³, and the specific gravity value is approximately 2.7.

- Q: Can aluminum coils be utilized in the process of welding?

- <p>Yes, aluminum coils can be used for welding work. They are commonly used as filler material in processes like MIG (Metal Inert Gas) welding. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need for shielding from oxidation. The aluminum coils must be of good quality and compatible with the welding process to ensure a strong and durable weld. Proper selection of welding parameters, such as amperage and voltage, is crucial for successful aluminum welding.</p>

- Q: How are aluminum coils cut to length?

- The process of cutting aluminum coils to length is typically done using two methods: shearing and slitting. Shearing involves the use of sharp blades to cut the coil into shorter lengths, which is commonly used for thicker coils. On the other hand, slitting is a process where the coil is passed through rotating circular knives to cut it into narrower strips of the desired width, often used for thinner coils. Both shearing and slitting can be done manually or automatically, depending on the scale of production and project requirements. Large-scale production usually utilizes automated cutting machines for their higher precision and faster cutting speeds. It is important to note that during the cutting process, the coil is usually uncoiled and guided through the cutting machine. Once the desired length or width is achieved, the cut aluminum pieces are collected, bundled, and prepared for further processing or distribution.

Send your message to us

Polished aluminum mirror coil for sale 1050 1100 3003 5052 high brightness mirror aluminum coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords