6061 T6 Aluminum Plate Flatness

6061 T6 Aluminum Plate Flatness Related Searches

6061 T6 Aluminum Plate 6061-T6 Aluminum Plate 6061 Aluminum Plate Thickness T6061 Aluminum Plate Aluminum 6061 Plate Mic 6 Aluminum Plate Flatness 6063 T6 Aluminum Plate Aluminum Plate 6061 6061 Aluminum Alloy Plate Bending 6061 Aluminum Plate 6061 0 Aluminum Plate Aluminum T6 6061 6060 Aluminum Plate 6061 T6 Aluminum Sheet 6061 Aluminum Tread Plate 6061 Aluminum Tooling Plate 6061 Aluminum Plate Tolerances 6061 T651 Aluminum Plate T6 Aluminum Plate 6061 Aluminum Diamond Plate Metric 6061 Aluminum Plate 6061-T651 Aluminum Plate 6082 T6 Aluminum Plate 1 4 6061 Aluminum Plate 1/2 6061 Aluminum Plate 6101 T6 Aluminum Plate Aluminum Tooling Plate Flatness 1/4 6061 Aluminum Plate 1 2 6061 Aluminum Plate 6061 Aluminum Plate Price6061 T6 Aluminum Plate Flatness Supplier & Manufacturer from China

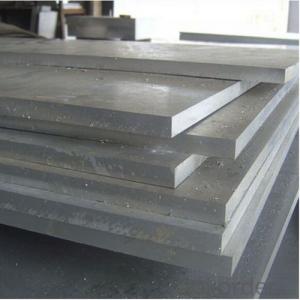

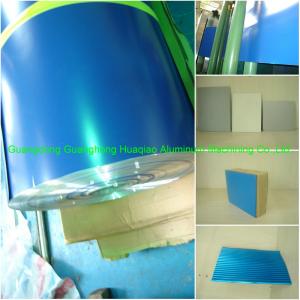

6061 T6 Aluminum Plate Flatness is a high-quality aluminum product known for its excellent strength, corrosion resistance, and workability. It is widely used in various industries such as aerospace, automotive, and construction due to its superior properties. This product is particularly favored for applications where a combination of strength and light weight is required, making it an ideal choice for components that need to withstand heavy loads while maintaining a low overall weight.The 6061 T6 Aluminum Plate Flatness is utilized in a broad range of applications, including structural components, transportation equipment, and architectural projects. Its flatness and dimensional stability make it suitable for precision machining and fabrication, ensuring that the end product meets the highest standards of quality and performance. Whether it's used in the manufacturing of aircraft parts, automotive components, or architectural structures, this aluminum plate's flatness plays a crucial role in ensuring the accuracy and reliability of the final product.

Okorder.com is a leading wholesale supplier of 6061 T6 Aluminum Plate Flatness, offering a vast inventory to cater to the needs of various industries. With a strong commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum plates they provide meet the highest industry standards. Their extensive inventory allows customers to access the product in large quantities, making it an ideal choice for businesses looking to source high-quality aluminum plates for their projects.

Hot Products